Inspecting, bearings

Use this procedure to inspect the bearings, balancing device.

NoteAction

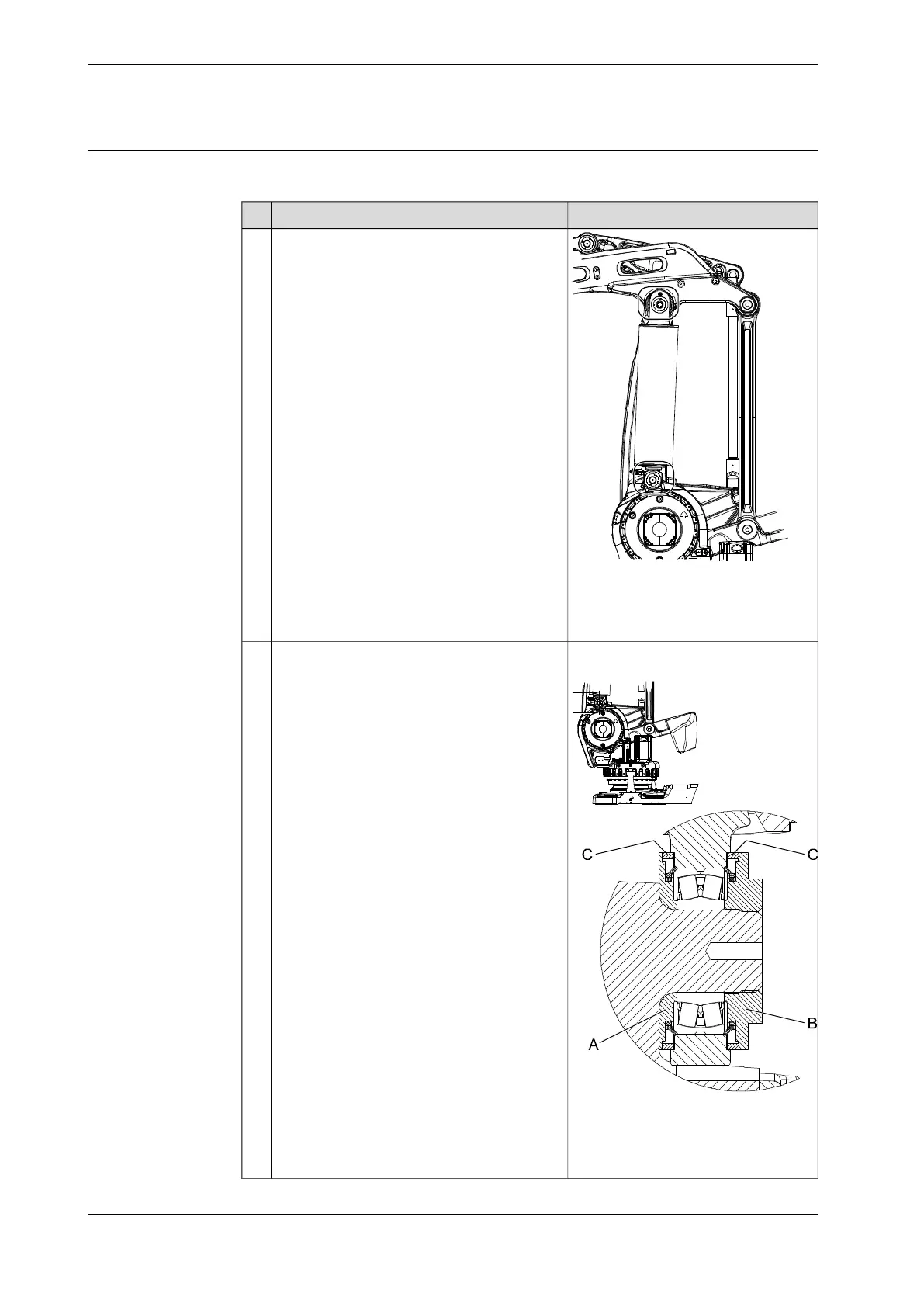

xx1000001130

Check for dissonance from the bearings at ear

and from the piston rod attachment.

Replace the bearing, if dissonance is detected.

1

Replacement is detailed in section Re-

placing the balancing device on

page 265.

See Replacing the balancing device on

page 265.

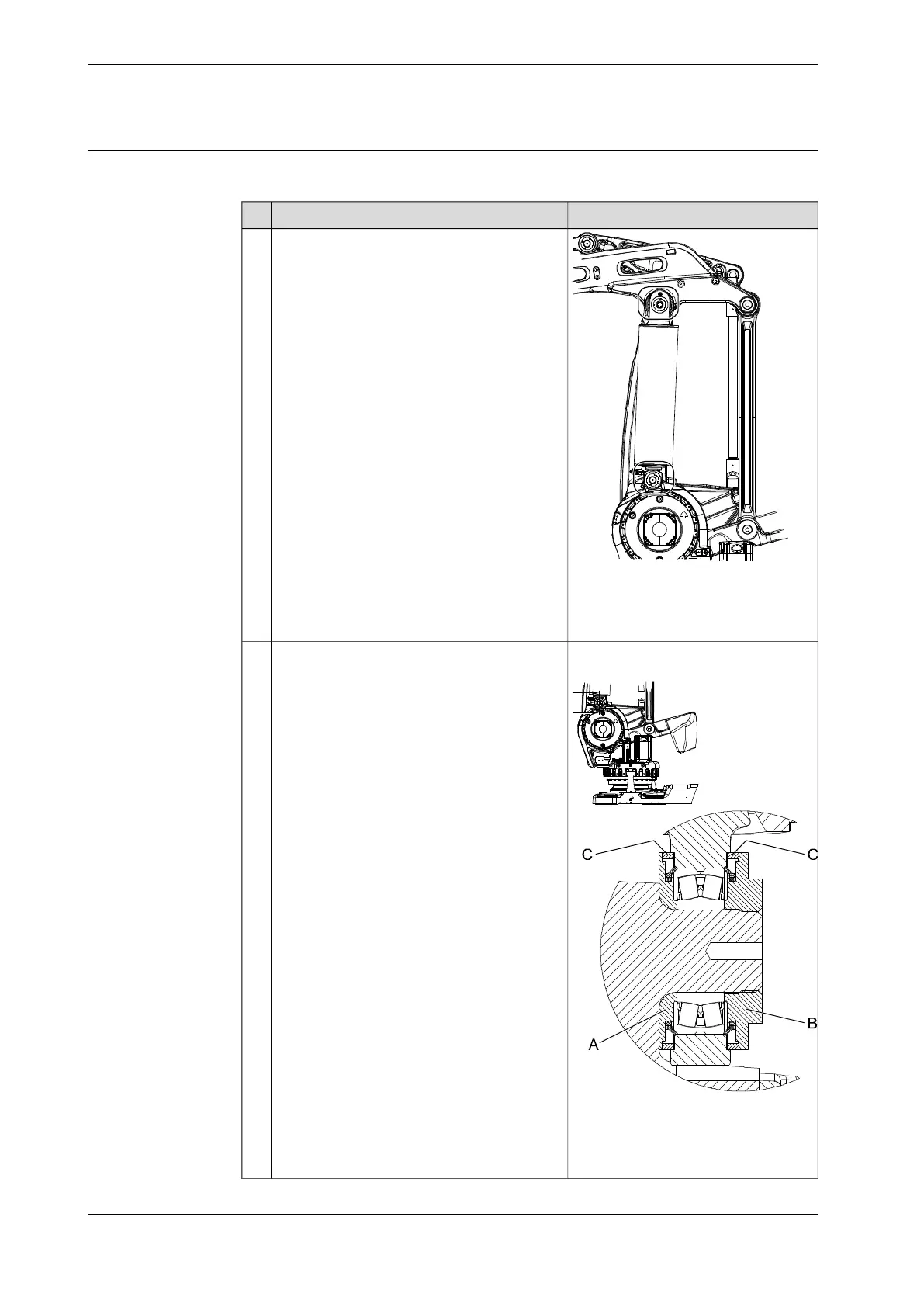

xx1000001145

Check for grease leakage from bearings. If

leakage is suspected, fault trace according to

following step-by-step instruction:

• Clean the area of old grease.

• Run the robot for a few minutes in order

to move the balancing device piston.

• Check for leakage. Leakage from the

inner side of attachment signifies a

damaged spacer ring while leakage from

the outer side signifies a damaged lock

nut. Replace damaged component.

2

A Spacer ring

B Lock nut KM10

C Support washers (2 pcs)

Continues on next page

112 3HAC039838-001 Revision: C

© Copyright 2013 ABB. All rights reserved.

3 Maintenance

3.3.4 Inspecting, balancing device bearings and piston rod guide ring

Continued

Loading...

Loading...