4.2 General procedures

4.2.1 Performing a leak-down test

General

After refitting any motor and gearbox, the integrity of all seals enclosing the gearbox

oil must be tested. This is done in a leak-down test.

Required equipment

NoteArt. no.Equipment, etc.

3HAC0207-1Leakdown tester

-Leak detection spray

Procedure

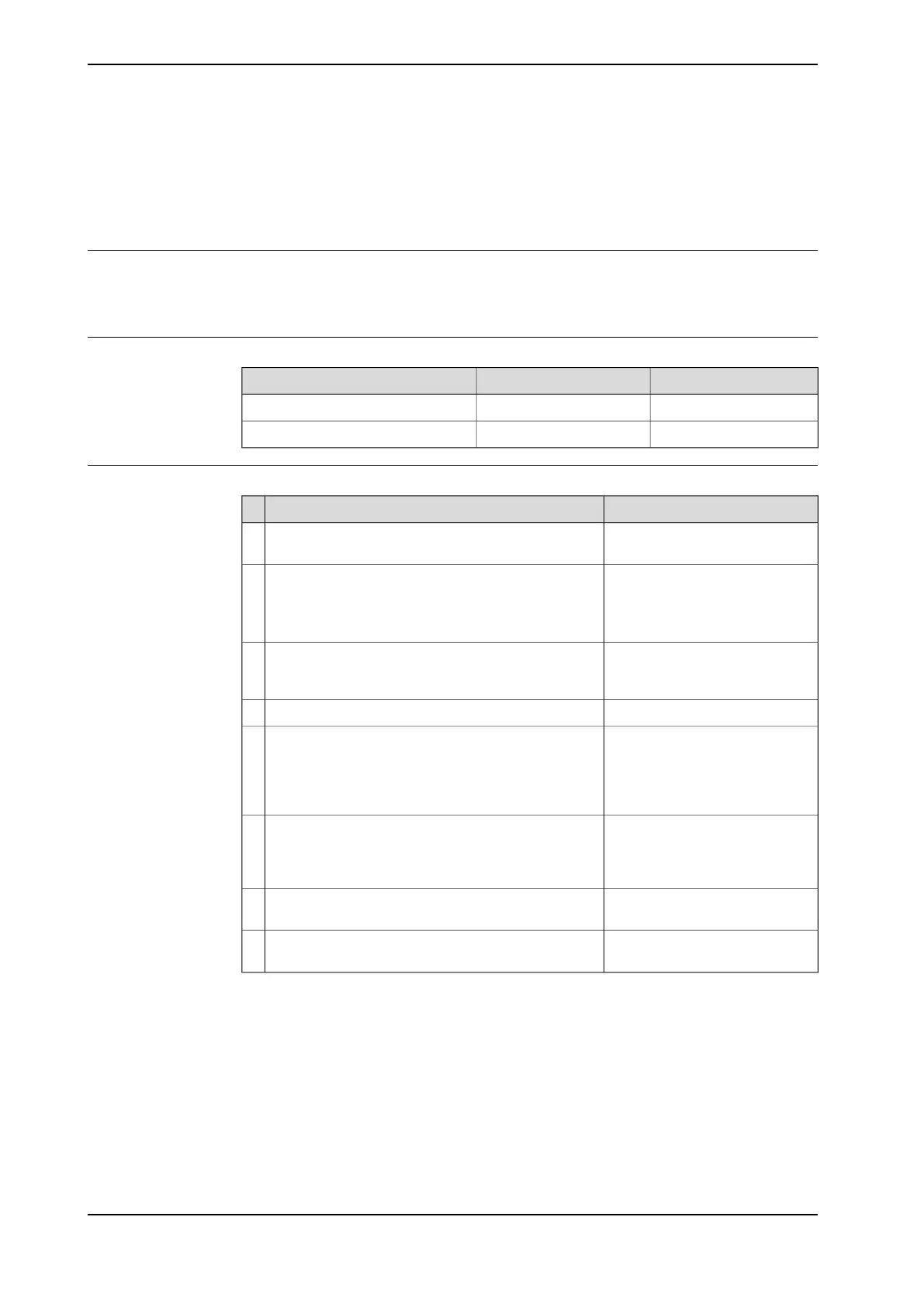

NoteAction

Finish the refitting procedure of the motor or gear in

question.

1

Art. no. is specified in Required

equipment on page 148.

Remove the topmost oil plug on the gear in question

and replace it with the leakdown tester.

Adapters, which are included in the leakdown tester

kit, may be required.

2

Correct value:Apply compressed air and raise the pressure with

the knob until the correct value is shown on the

manometer.

3

0.2 - 0.25 bar (20 - 25 kPa)

Disconnect the compressed air supply.4

If the compressed air is signific-

antly colder or warmer than the

gearbox to be tested, a slight

pressure increase or decrease

may occur. This is quite normal.

Wait for approx. 8-10 minutes. No pressure loss may

be detected.

5

Was any pressure drop evident?

6

Localize the leak as detailed below.

Remove the leakdown tester and refit the oil plug.

The test is complete.

Spray suspected leak areas with leak detection spray.

Bubbles indicate a leak.

7

When the leak has been localized, take the necessary

measures to correct the leak.

8

148 3HAC039838-001 Revision: C

© Copyright 2013 ABB. All rights reserved.

4 Repair

4.2.1 Performing a leak-down test

Loading...

Loading...