TPU2000/2000R Modbus/Modbus Plus Automation Guide

63

Discrete

Address

Item Description

01048 OUT 4 Physical Output Contact 4 Change Detect Between Scans

01049 OUT 3 Physical Output Contact 3

01050 OUT 3 Physical Output Contact 3 Change Detect Between Scans

01051 OUT 2 Physical Output Contact 2

01052 OUT 2 Physical Output Contact 2 Change Detect Between Scans

01053 OUT 1 Physical Output Contact 1

01054 OUT 1 Physical Output Contact 1 Change Detect Between Scans

01055 TRIP Status Breaker Trip Physical Output Contact

01056 TRIP Momentary Breaker Trip Physical Output Contact Change Detect Between Scans

1X Discrete Contact Inputs

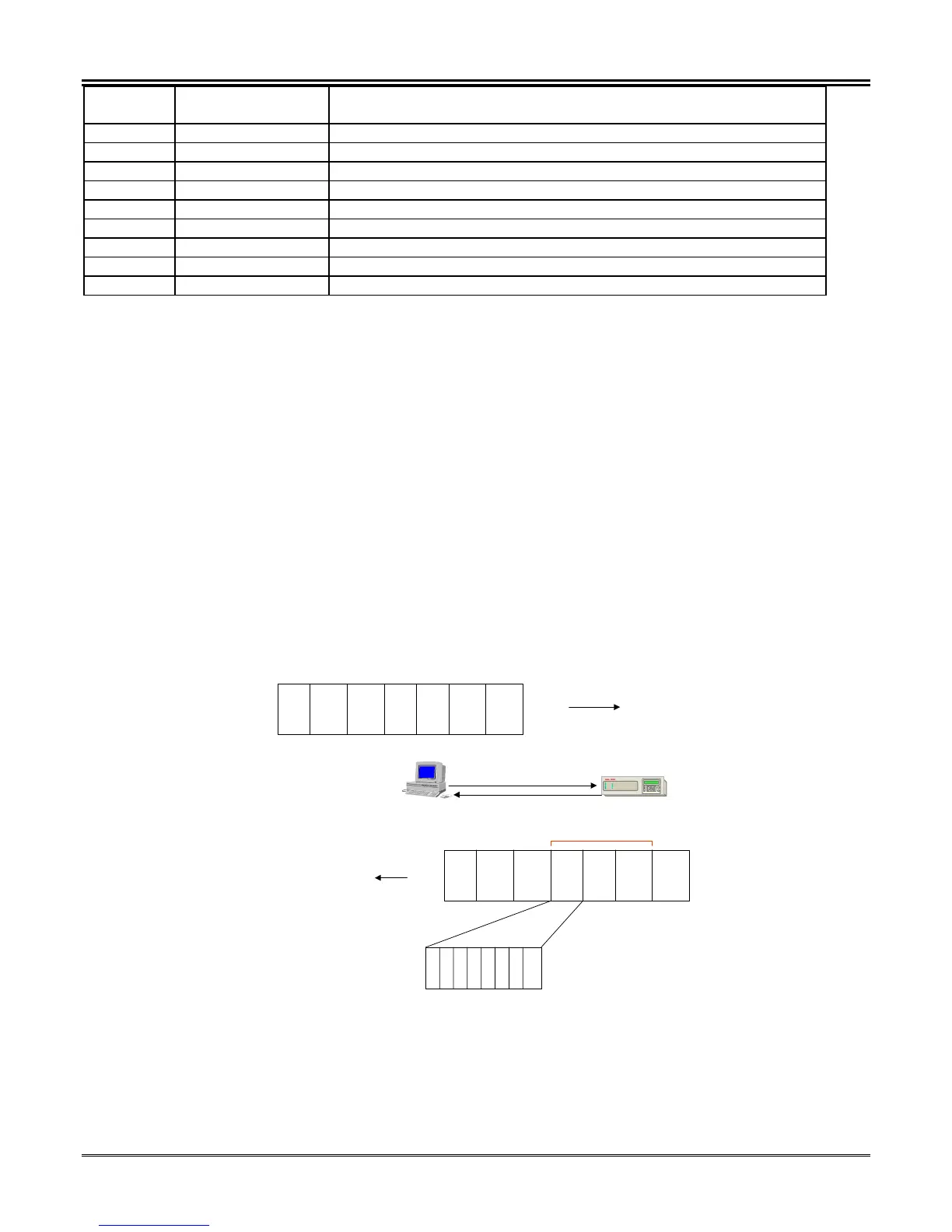

Discrete physical input and relay element status are available via a function 02 request through Modbus and

through a Modbus Plus Host. The TPU2000/2000R does not support the Modbus Plus feature of PEER COP

thus 1X data cannot be obtained from a PLC (Programmable Logic Controller) supporting such a feature. Figure

5-19 illustrates a typical command sequence. The Host polls the TPU2000R for the Data. The TPU2000R

receives the request and responds with the expected data. The Host then interprets the command response,

checks the LRC checksum in ASCII mode and then displays the interpreted data. If the node is configured for

RTU Modbus, the start of message character is three character delays, and the end of message consists of a

CRC-16 checksum and three character delays. Additional information is available in Modicon’s protocol manual

references listed at the beginning of this document. The same information is available through a 4X register read

command, which allows a host without 1X data accesses capabilities to obtain physical input and relay element

information. Tables 5-5 through 5-9 list the 1X discrete contact memory map as defined for Modbus RTU and

ASCII. Modbus Plus embeds the Modbus message in its structure. Please reference Section 5 of this document

for a more complete discussion of Modbus Plus message structure.

Function Code 2 - Read Input Status (Read Only Data)

Figure 5-19 illustrates the command format required for execution of function code 2.

Modbus Host

Modbus Slave Addr =1

Read from

1X Mapping

Slave

Addr.

Funct.

Code

02

Start

Addr

HI

Start

Addr

LO

Coils

Read

HI

Coils

Read

LO

Error

Check

EOM

SOM

Slave

Addr.

Funct.

Code

02

Byte

Count

*

Data

Byte

1

…..

Data

Byte

NNN

Error

Check

EOM

SOM

Byte 1 …2……..3…….4…….5……6……..7….

MSB LSB

87

65

4321

SOM = Start of

Message Header

EOM = End of

Message Header

E

C

Figure 5-19. 1X Input Request Using Modbus Command 02

It should be noted that every TPU2000R allows real time status reporting when the unit is polled. If a status is

momentary and is missed during the host poll, then the data is lost. Polling using the status Momentary Change

Detect Feature insures that the host device does not miss the momentary change. It should also be noted that

data requested from 1X data address ranges not defined within this document generates Modbus exception

codes.

Loading...

Loading...