ENGINE

3 - 62

ENGINES C361M / C364M

3.11.9. RECOMPOSITION OF THE CRANKCASE AND

DRIVE SHAFT

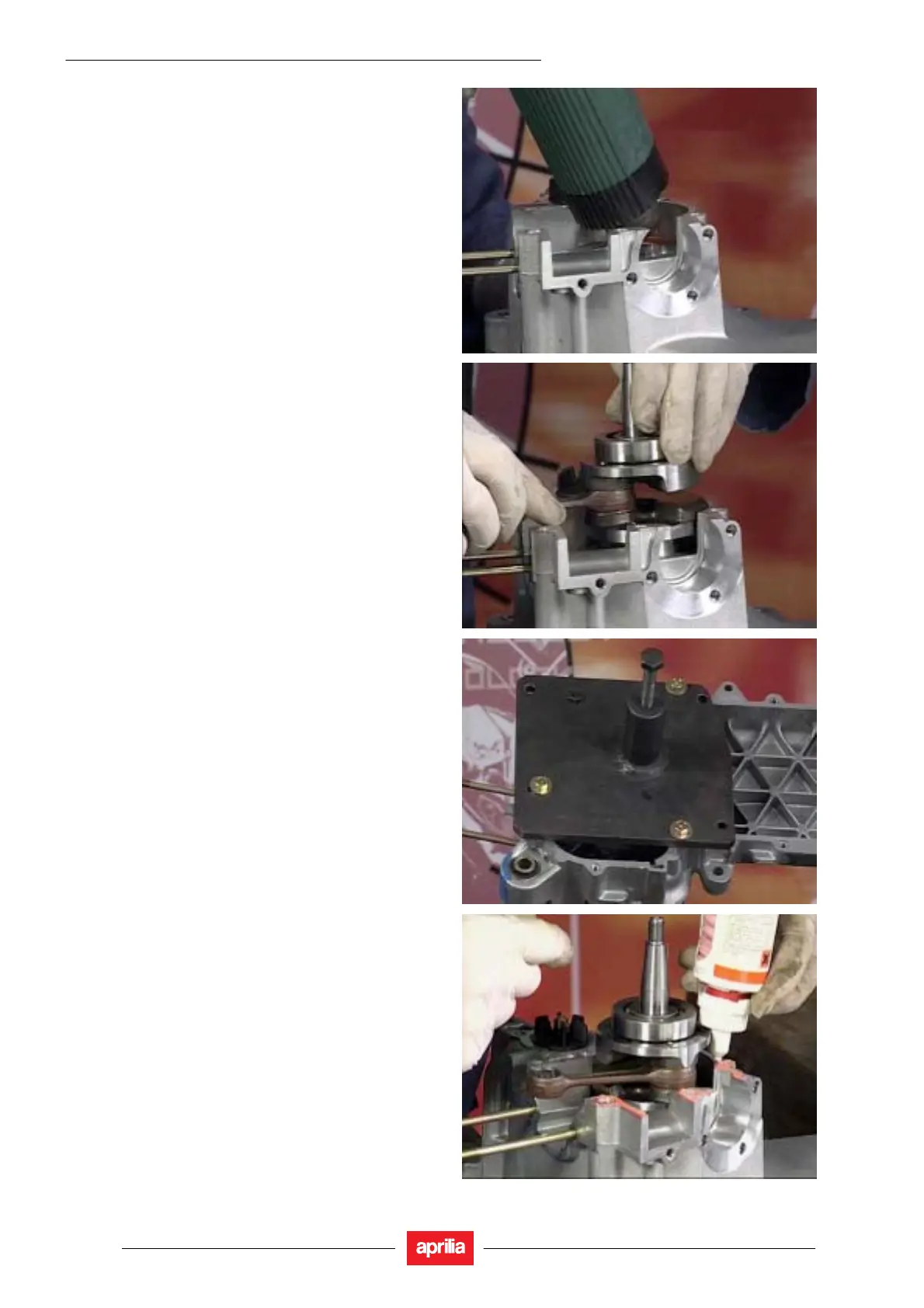

• Position the half-case on two suitable supports. Use a

heat gun to heat the seat of the bearing to about

120°C.

• Insert the drive shaft until the bearing reaches its end

of travel stops. Make sure the con rod is aligned with

the axis of the cylinder.

• Reinstall the specific crankcase separation plate. Do

not install the drive shaft guard.

• Slacken the central thrust bolt during the reassembly

operations. Bring the attachment bolts ot the end of

their travel and then slacken them to the same angle.

• When the temperature is steady, preload the thrust bolt

of the tool just enough to cancel the play of the balls of

the bearing.

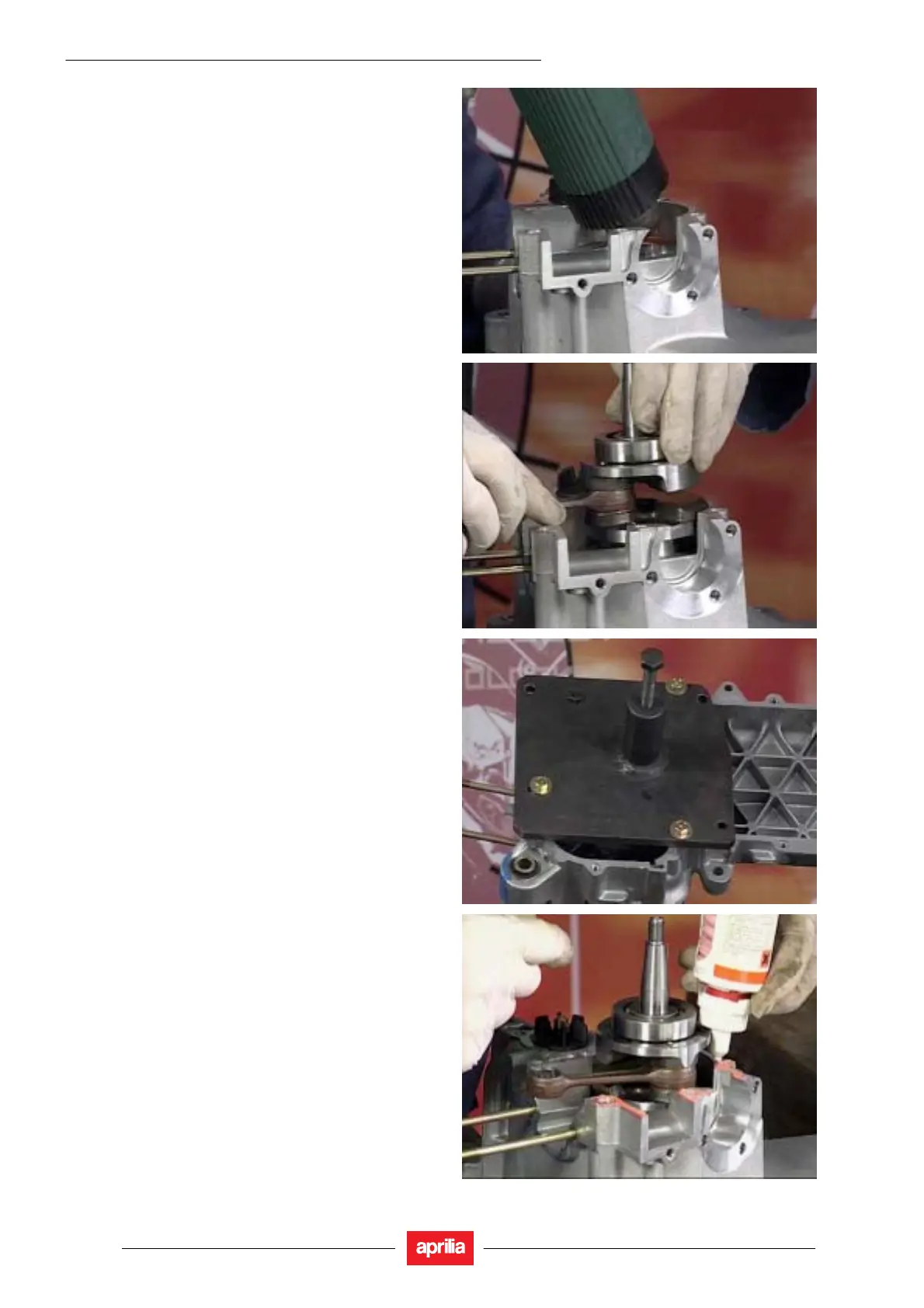

• Degrease the surface with an appropriate solvent and

apply a thin layer of Loctite.

Loading...

Loading...