Checking combustion CO

2

The CO

2

percentage is set in the factory. This has to be checked during commissioning,

inspection, maintenance and in case of a failure.

CO

2

High Load reading

This can be verified by means of the following action:

• Ensure that the boiler is in operation and that the heat, which it produces,

can be discharged

• If taps are opened the internal diverter motor will move and heat can be discharged

through the hot water side of the boiler. (multiple taps open is preferred)

• Calibrate the flue gas analyser

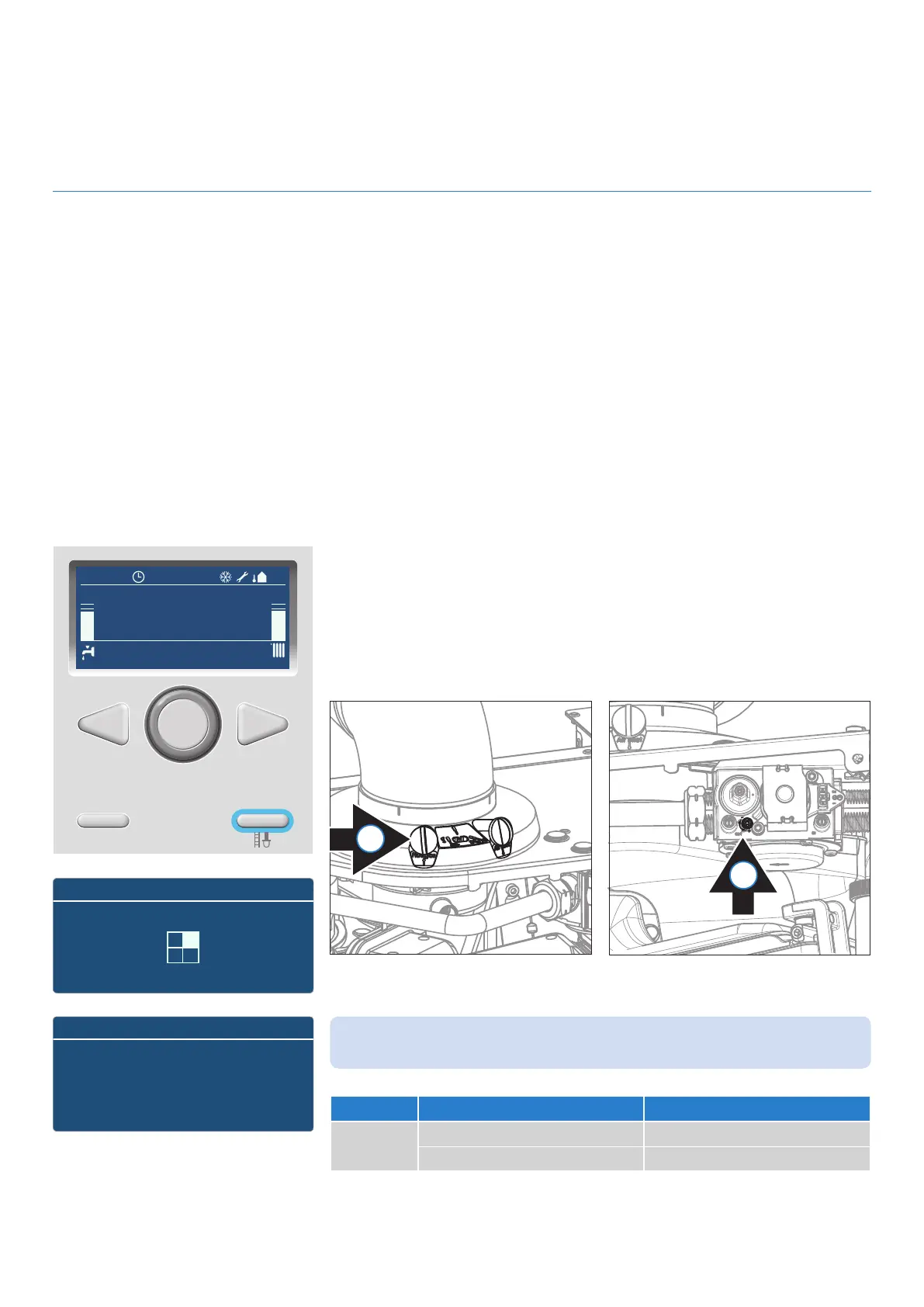

• Place the lance of the flue gas analyser into the flue gas test point

After this check has been done at full load, the CO

2

value at low load need to be tested.

If there are any deviations in the result, then these must be corrected (see Step 3).

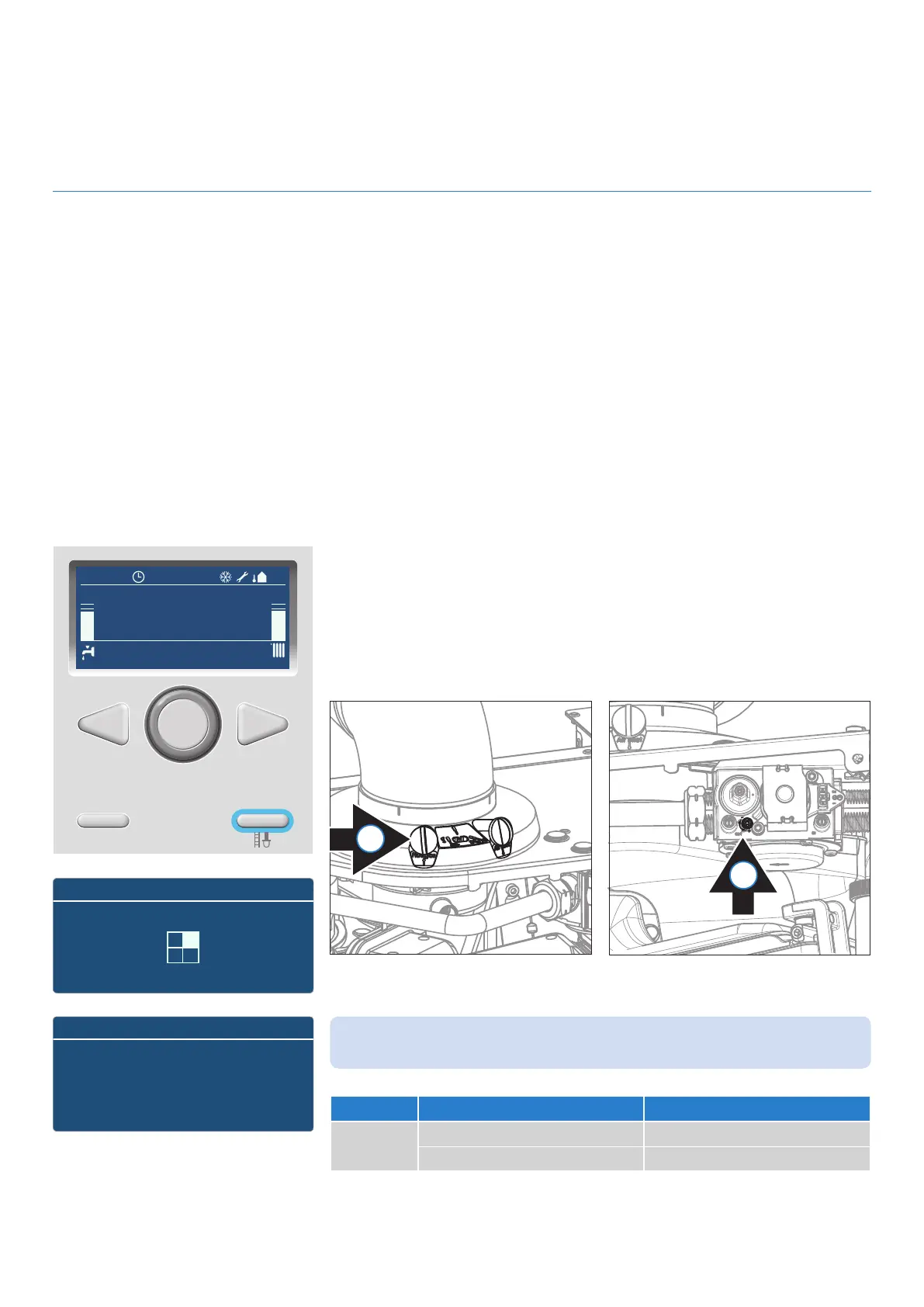

• Press the chimney sweep button for 5 seconds;

• Turn the selector wheel until you reach 100%;

• Press OK; The boiler will switch to maximum power output (full load) of the boiler;

the screen shows 100% (heating capacity)

• Calibrate the Flue Gas Analyser, and then insert the flue gas probe of the Flue Gas Analyser

into the measuring point of the flue gas pipe “A” (see illustration)

• Wait for one minute and then carry out a combustion analysis

• Check whether the CO

2

values that are listed below correspond to the measured value

* Only possible if LPG conversion kit is installed! Note: Values are valid with closed cover/air box.

FULL LOAD NATURAL GAS G20 PROPANE GAS LPG G31*

CO

2

Nominal 9.0% Nominal 10.3%

Minimum 8.6% – Maximum 9.6% Minimum 9.9% – Maximum 11.0%

If required, you may turn the setting screw

"B" (see above illustration) to set the correct CO

2

percentage.

RESET

BACK OK

19°25/07/18 09:00

80°60°

ECO AUTO

Press OK to enter Menu

1.5 bar

Step 1: Set the full load

You can set the full load of the boiler as follows:

A

B

A - Measuring point for the flue gas probe B - Set screw for CO

2

22

Loading...

Loading...