7.

Tab.62 Distances and tolerances to be observed for the ignition electrode

and the burner

D

Distance POWER HT+ 1.50, POWER HT+ 1.70, POWER HT+ 1.90,

POWER HT+ 1.110

Ignition electrode and ground electrode 4 mm with a tolerance of +/- 0.5 mm

Check the distance between the ignition electrode and the ground

electrode.

Replace the ignition electrode if it is damaged.

8. Check whether the insulation on the inside surface of the burner is

damaged in any way. The surface must be clean and free of any

damage. Replace the insulation if it is damaged.

9. Remount the burner.

Remounting the burner, page 111

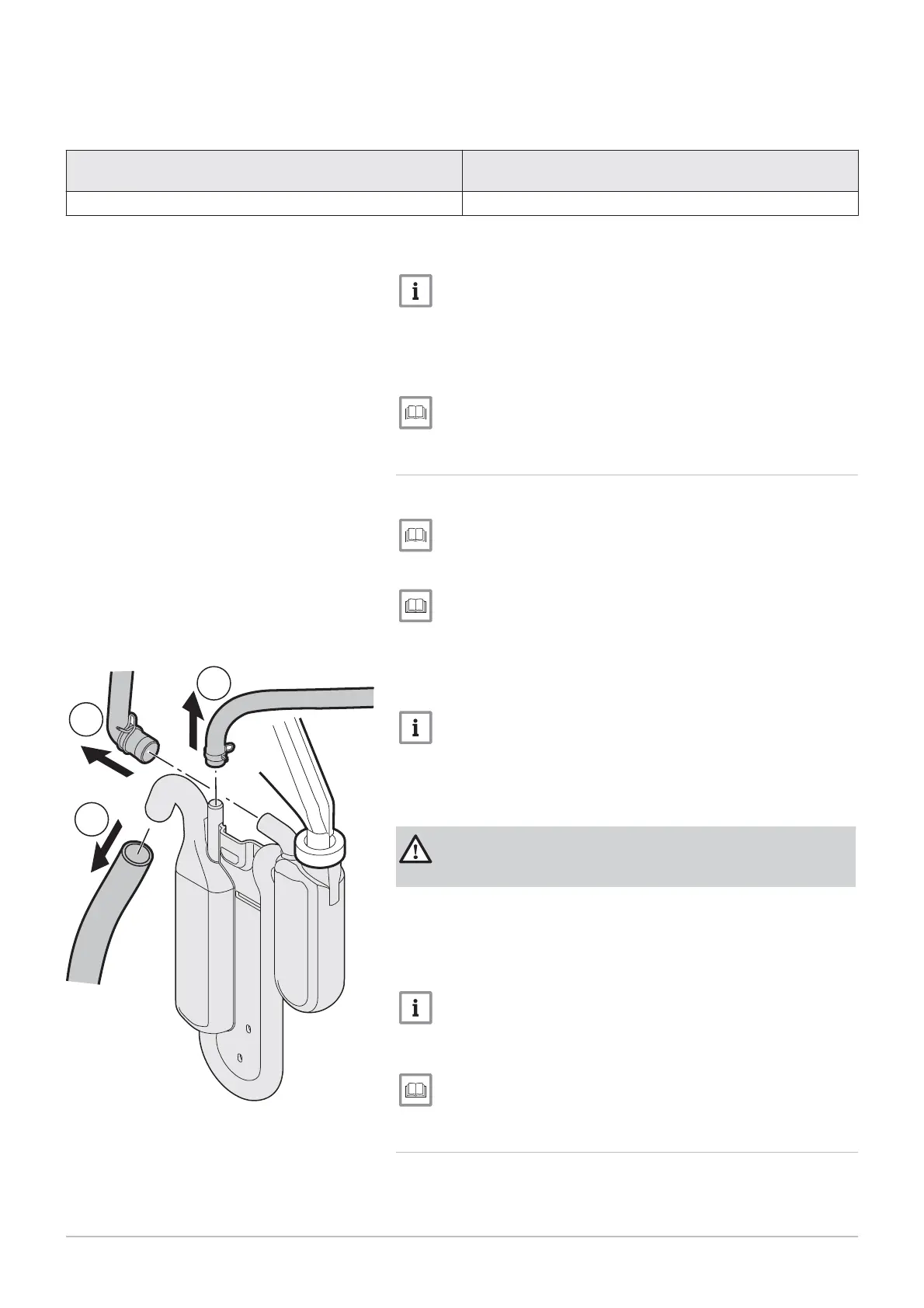

10.2.5 Cleaning the siphon

1. Remove the burner.

Removing the burner, page 107.

2. Access the siphon.

Accessing the internal boiler components, page 37

3. Disconnect the pipe from the combustion chamber (only on POWER

HT+ 1.50 and POWER HT+ 1.70).

4. Disconnect the pipe from the exchanger for the flue gases.

5. Disconnect the condensates discharge pipe.

Use a pair of pliers to remove the spring tightening clamps.

6. Remove the siphon from the heating body by taking out the retaining

screw with a cross-head screwdriver.

7. Clean the bottom of the siphon with water.

8. Completely fill the siphon.

Fill the siphon to the top. If the siphon is empty, there is a danger

of intoxication by exhaust gases.

9. Put the siphon back on the heating body and put the retaining screw

back in place with a cross-head screwdriver.

10. Reconnect the pipe from the combustion chamber, the pipe from the

exchanger for the flue gases and, finally, the condensates discharge

pipe.

Use a pair of pliers to put the spring tightening clamps back in

place.

11. Remount the burner.

Remounting the burner, page 111.

10.2.6 Remounting the burner

1. Remount the pipe connecting the gas valve to the Venturi unit.

2. Remount the burner, the Venturi and the fan.

Fig.

144

Distances and tolerances to be ob

served for the ignition electrode and

the ground electrode

Fig.

145

Removing the siphon

MW-3000104

5

4

3

10 Maintenance

7609474 - v02 - 04092014 111

Loading...

Loading...