7

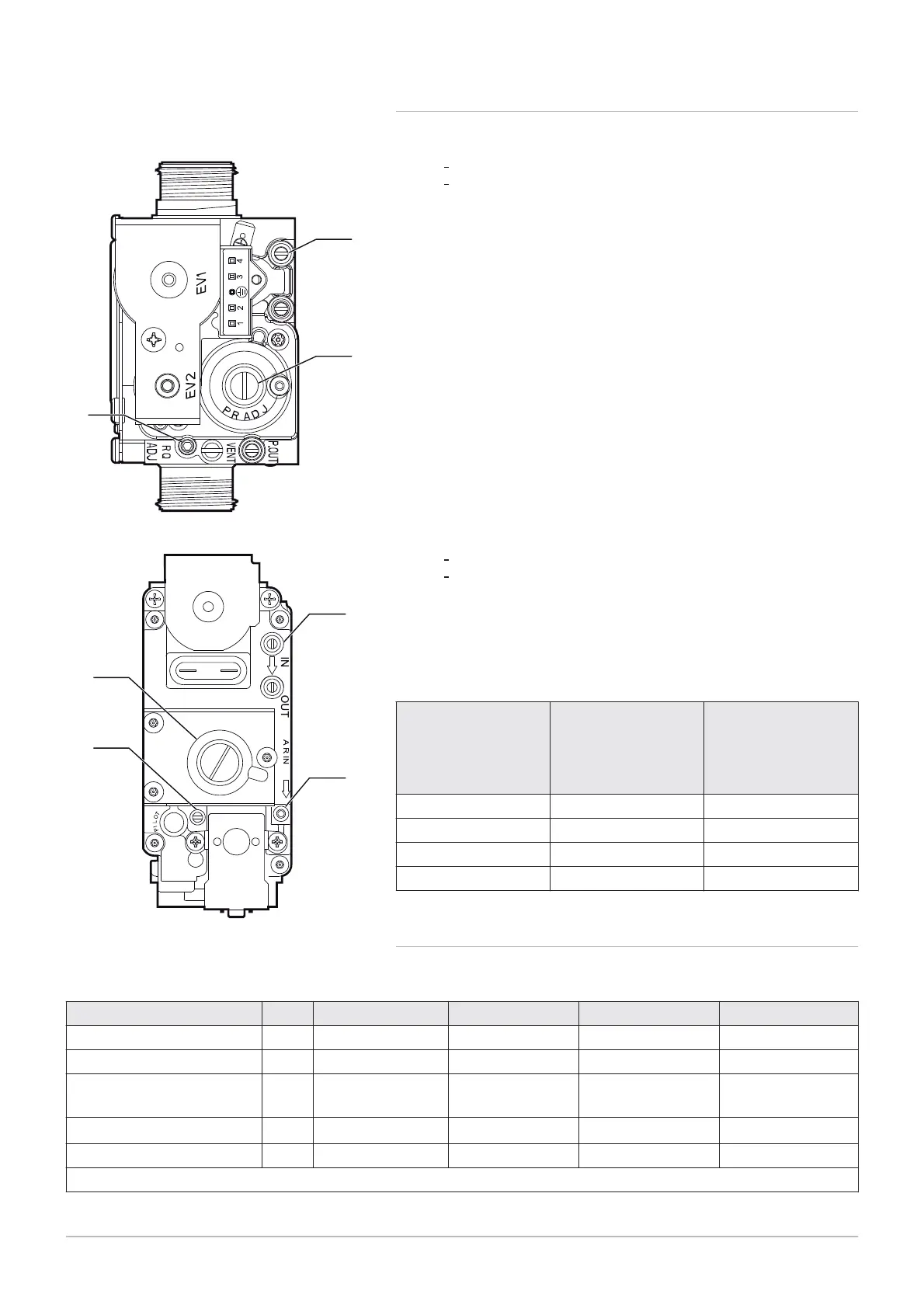

Gas flow rate setting screw

OFFSET setting screw:

Remove the plug

Use a 4 mm hexagonal spanner

Gas supply pressure outlet

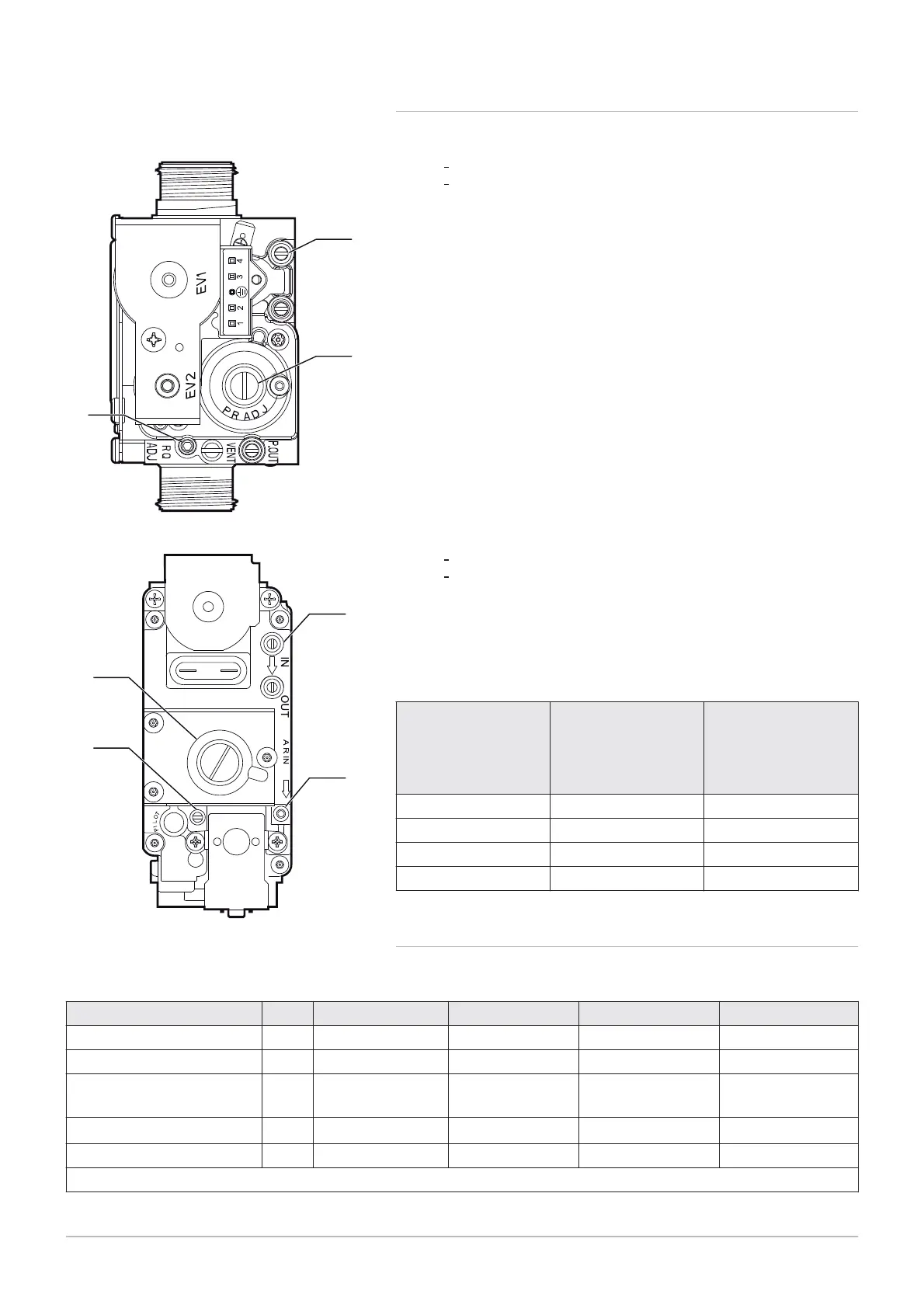

Gas flow rate setting screw

OFFSET setting screw:

Remove the plug

Use a flat-blade screwdriver

Sealed chamber pressure signal

Gas supply pressure outlet

Tab.23 Settings values for a new gas valve on POWER HT +

The settings screw is screwed down as far as it will go and is then is un

screwed according to the number of turns given in the following table.

Boiler model Nominal heating flow

rate:

Number of turns for the

gas flow rate settings

screw

Minimum heating flow

rate:

Number of turns for the

OFFSET settings

screw

POWER HT+ 1.50 12 5 + 3/4

POWER HT+ 1.70 13 5 + 3/4

POWER HT+ 1.90 2 + 2/3 5 + 3/4

POWER HT+ 1.110 2 + 1/3 5 + 3/4

7.4.5 CO

2

checking and setting values

Tab.24 Checking and setting values for gas type G20

Unit POWER HT+ 1.50 POWER HT+ 1.70 POWER HT+ 1.90 POWER HT+ 1.110

Diameter of the Venturi mm 24 30 34 38

Diameter of the nozzles mm 3.70 (no. 2) 5.30 (no. 2) 5.60 (no. 2) 6.40 (no. 2)

Minimum CO

2

(1)

% 8.5 8.5 8.5 9.0

Maximum CO

2

(1)

% 9.0 9.0 9.0 9.2

Maximum CO ppm < 250 < 250 < 250 < 250

(1) The CO

2

value is valid with the front panel mounted. If the front panel is removed (open chamber), the value readout is lower by 0.2%.

Fig.66 POWER HT+ 1.50 – POWER HT+

1.70

MW-3000045-01

1

2

3

Fig.67 POWER HT+ 1.90 – POWER HT+

1.110

MW-3000047-01

3

1

2

4

7 Commissioning

62 7609474 - v02 - 04092014

Loading...

Loading...