Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

9

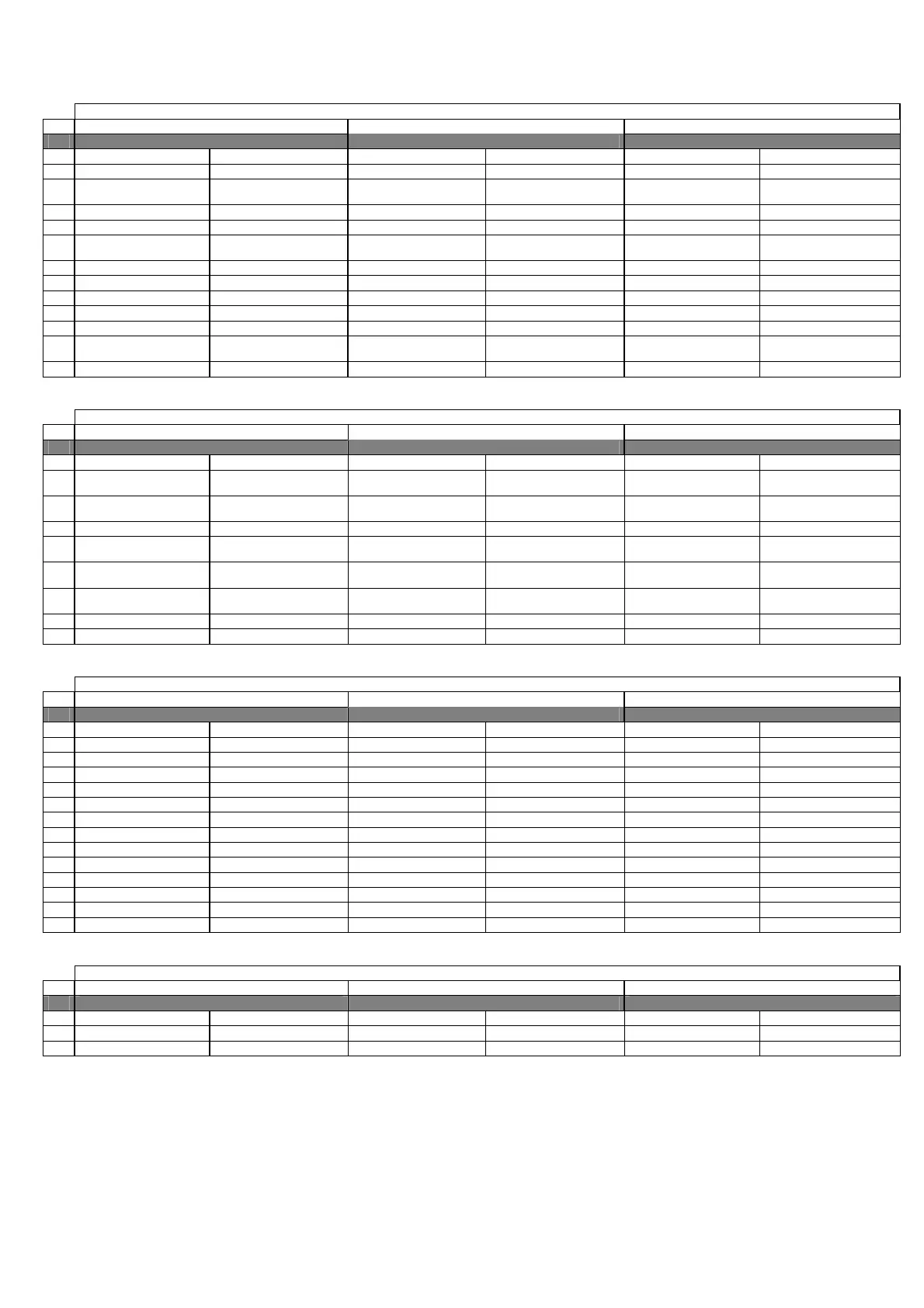

6.2 CHILLER UNIT + HEAT PUMP – MACHINE TYPE “1”

6.2.1 DIGITAL INPUTS

Chiller unit + heat pump MACHINE TYPE “1”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4)

1

Serious alarm (enablable) Serious alarm (enablable) Serious alarm (enablable) Serious alarm (enablable) Serious alarm (enablable) Serious alarm (enablable)

2

Evaporator Flow-switch

(enablable)

Evaporator Flow-switch

(enablable)

Evaporator Flow-switch

(enablable)

Evaporator Flow-switch

(enablable)

Evaporator Flow-switch

(enablable)

Evaporator Flow-switch

(enablable)

3

Remote ON/OFF Remote ON/OFF Remote ON/OFF Remote ON/OFF Remote ON/OFF Remote ON/OFF

4

Pump Thermal cutout Pump Thermal cutout Pump Thermal cutout

5

Low Pressure Pressure-

switch 1

Low Pressure Pressure-

switch 2

Low Pressure Pressure-

switch 1

Low Pressure Pressure-

switch 2

Low Pressure Pressure-

switch 1

Low Pressure Pressure-

switch 2

6

Differential / Oil Level Differential / Oil Level Differential / Oil Level Differential / Oil Level Differential / Oil Level Differential / Oil Level

7

Phase Monitor (enablable) Phase Monitor (enablable) Phase Monitor (enablable) Phase Monitor (enablable) Phase Monitor (enablable) Phase Monitor (enablable)

8

Double Set-point Double Set-point Double Set-point

9

Fan 1 Thermal cutout Fan 1 Thermal cutout Fan 1 Thermal cutout Fan 1 Thermal cutout Fan 1 Thermal cutout Fan 1 Thermal cutout

10

Summer / Winter Summer / Winter Summer / Winter

11

High Pressure Pressure-

switch

High Pressure Pressure-

switch

High Pressure Pressure-

switch

High Pressure Pressure-

switch

High Pressure Pressure-

switch

High Pressure Pressure-

switch

12

Compressor Thermal cutout Compressor Thermal cutout Compressor Thermal cutout Compressor Thermal cutout Compressor Thermal cutout Compressor Thermal cutout

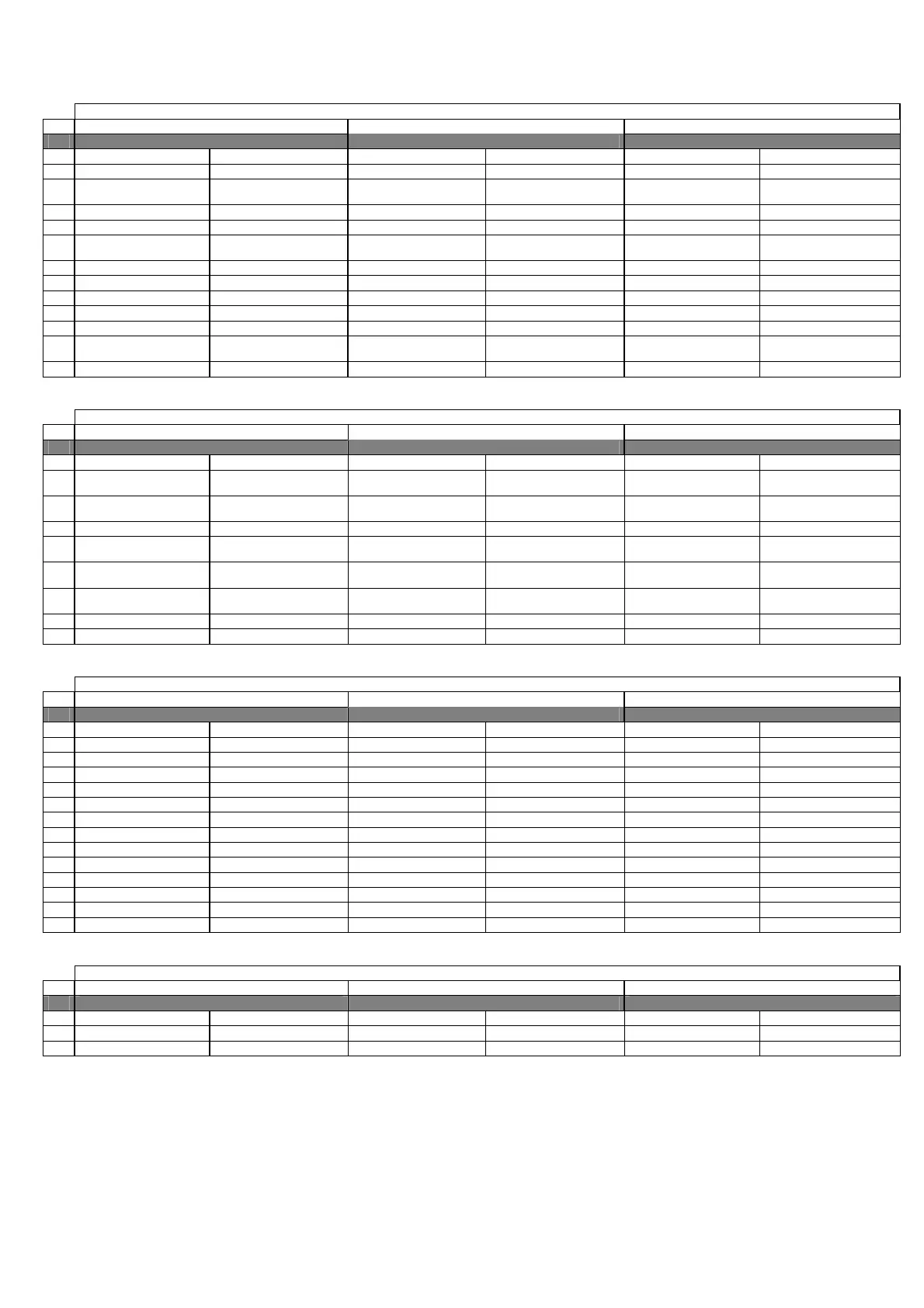

6.2.2 ANALOGUE INPUTS

Chiller unit + heat pump MACHINE TYPE “1”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4)

1

Water temperature at

Evaporator Inlet

High Pressure High Pressure Water temperature at

Evaporator Inlet

2

Water temperature at

Evaporator Outlet

Water temperature at

Evaporator Outlet

Low Pressure Low Pressure Water temperature at

Evaporator Outlet

Water temperature at

Evaporator Outlet

3

Delivery Temperature Delivery Temperature Delivery Temperature Delivery Temperature Condenser Temperature Condenser Temperature

4

Voltage / Current / External

Set-point

Voltage / Current

5

Condenser Temperature Condenser Temperature Water temperature at

Evaporator Inlet

Voltage / Current / External

Set-point

Voltage / Current

6

Voltage / Current / External

Set-point

Voltage / Current Water temperature at

Evaporator Outlet

Water temperature at

Evaporator Outlet

Delivery Temperature Delivery Temperature

7

High Pressure High Pressure Condenser Temperature Condenser Temperature High Pressure High Pressure

8

Low Pressure Low Pressure Low Pressure Low Pressure

6.2.3 DIGITAL OUTPUTS

Chiller unit + heat pump MACHINE TYPE “1”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4)

1

Circulation Pump Circulation Pump Circulation Pump

2

Line Contactor Line Contactor Line Contactor Line Contactor Line Contactor Line Contactor

3

Star Contactor Star Contactor Star Contactor Star Contactor Star Contactor Star Contactor

4

Triangle Contactor Triangle Contactor Triangle Contactor Triangle Contactor Triangle Contactor Triangle Contactor

5

Liquid Solenoid Liquid Solenoid Liquid Solenoid Liquid Solenoid Liquid Solenoid Liquid Solenoid

6

Capacity Control Relay 1 Capacity Control Relay 1 Capacity Control Relay 1 Capacity Control Relay 1 Capacity Control Relay 1 Capacity Control Relay 1

7

Capacity Control Relay 2 Capacity Control Relay 2 Capacity Control Relay 2 Capacity Control Relay 2 Capacity Control Relay 2 Capacity Control Relay 2

8

Capacity Control Relay 3 Capacity Control Relay 3 Capacity Control Relay 3 Capacity Control Relay 3 Capacity Control Relay 3 Capacity Control Relay 3

9

Liquid inj./Econ/Oil Cooler Liquid inj./Econ/Oil Cooler Liquid inj./Econ/Oil Cooler Liquid inj./Econ/Oil Cooler Liquid inj./Econ/Oil Cooler Liquid inj./Econ/Oil Cooler

10

Antifreeze Heater Antifreeze Heater Antifreeze Heater Antifreeze Heater Antifreeze Heater Antifreeze Heater

11

General Alarm General Alarm General Alarm General Alarm General Alarm General Alarm

12

4-wayValve 4-wayValve 4-wayValve 4-wayValve 4-wayValve 4-wayValve

13

Fan 1 Fan 1 Fan 1 Fan 1 Fan 1 Fan 1

6.2.4 ANALOGUE OUTPUTS

Chiller unit + heat pump MACHINE TYPE “1”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4)

1

2

Speed Controller Speed Controller Speed Controller Speed Controller Speed Controller Speed Controller

Loading...

Loading...