Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

10

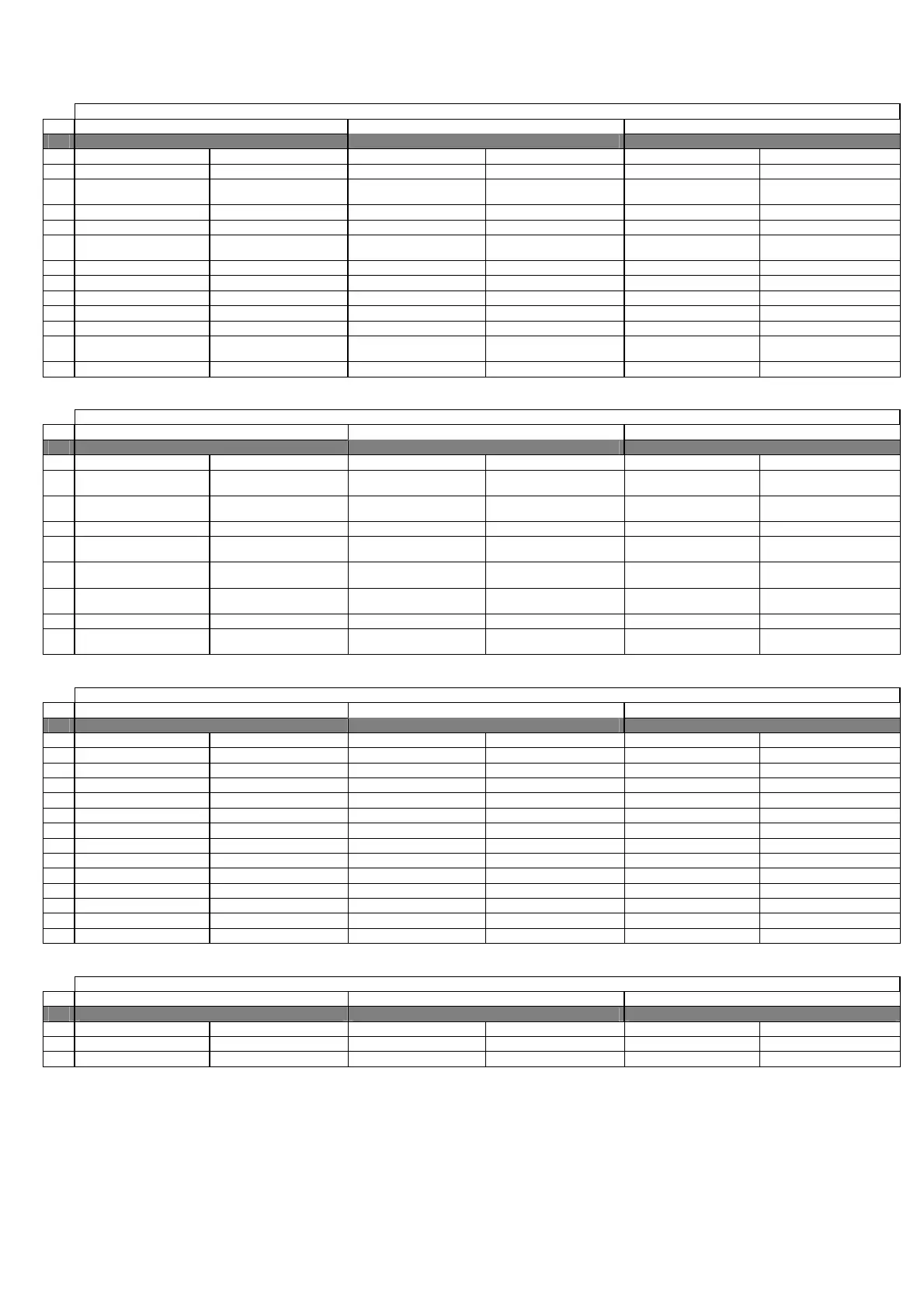

6.3 CHILLER UNIT WITH FREECOOLING – MACHINE TYPE “2”

6.3.1 DIGITAL INPUTS

Chiller unit with freecooling MACHINE TYPE “2”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4)

1

Serious alarm (enablable) Serious alarm (enablable) Serious alarm (enablable) Serious alarm (enablable) Serious alarm (enablable) Serious alarm (enablable)

2

Evaporator Flow-switch

(enablable)

Evaporator Flow-switch

(enablable)

Evaporator Flow-switch

(enablable)

Evaporator Flow-switch

(enablable)

Evaporator Flow-switch

(enablable)

Evaporator Flow-switch

(enablable)

3

Remote ON/OFF Remote ON/OFF Remote ON/OFF Remote ON/OFF Remote ON/OFF Remote ON/OFF

4

Pump Thermal cutout Pump Thermal cutout Pump Thermal cutout

5

Low Pressure 2 Pressure-

switch

Low Pressure 2 Pressure-

switch

Low Pressure 2 Pressure-

switch

Low Pressure 2 Pressure-

switch

Low Pressure 2 Pressure-

switch

Low Pressure 2 Pressure-

switch

6

Differential / Oil Level Differential / Oil Level Differential / Oil Level Differential / Oil Level Differential / Oil Level Differential / Oil Level

7

Phase Monitor (enablable) Phase Monitor (enablable) Phase Monitor (enablable) Phase Monitor (enablable) Phase Monitor (enablable) Phase Monitor (enablable)

8

Double Set-point Double Set-point Double Set-point

9

Fan 1 Thermal cutout Fan 1 Thermal cutout Fan 1 Thermal cutout Fan 1 Thermal cutout Fan 1 Thermal cutout Fan 1 Thermal cutout

10

Fan 2 Thermal cutout Fan 2 Thermal cutout Fan 2 Thermal cutout Fan 2 Thermal cutout Fan 2 Thermal cutout Fan 2 Thermal cutout

11

High Pressure Pressure-

switch

High Pressure Pressure-

switch

High Pressure Pressure-

switch

High Pressure Pressure-

switch

High Pressure Pressure-

switch

High Pressure Pressure-

switch

12

Compressor Thermal cutout Compressor Thermal cutout Compressor Thermal cutout Compressor Thermal cutout Compressor Thermal cutout Compressor Thermal cutout

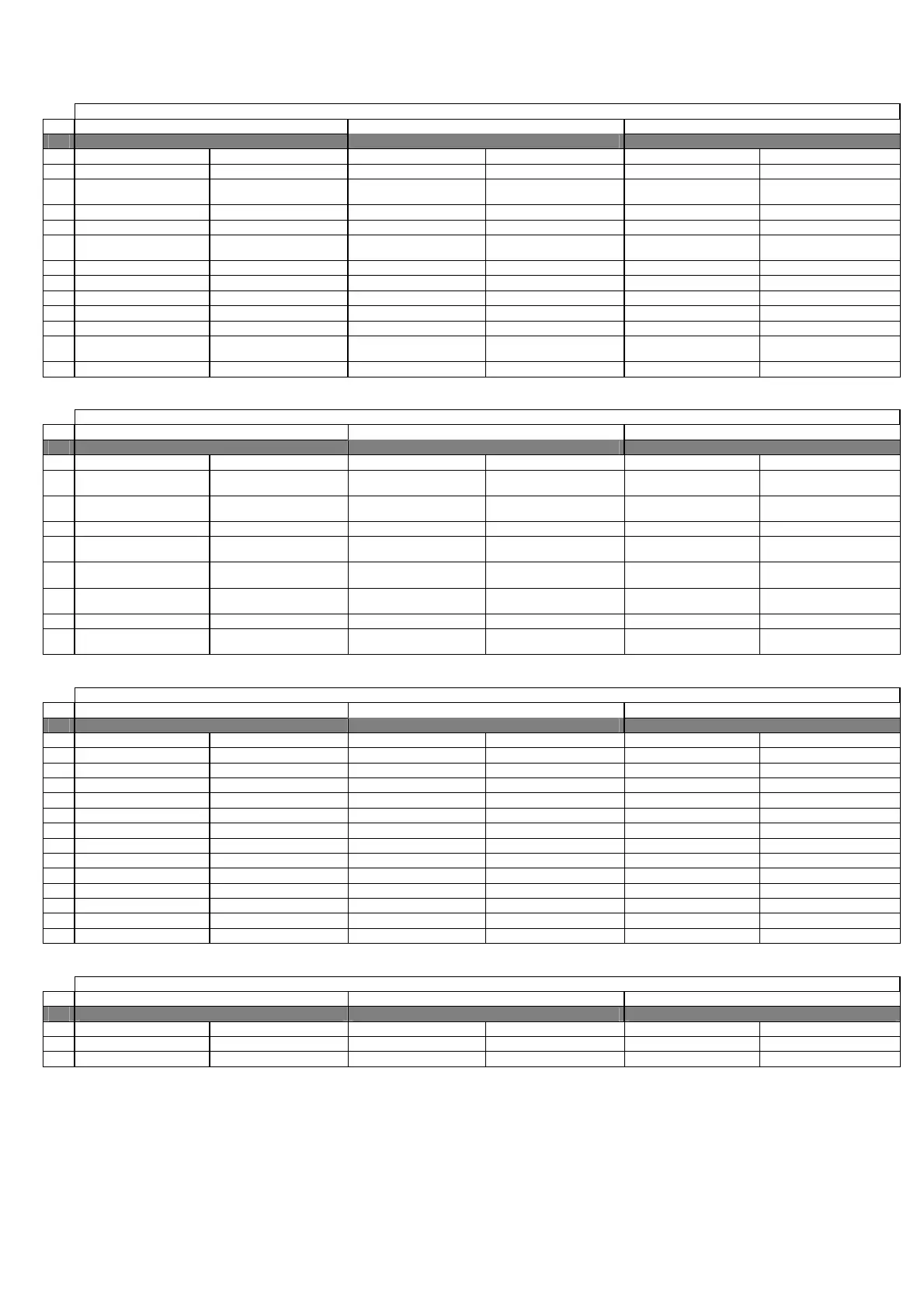

6.3.2 ANALOGUE INPUTS

Chiller unit with freecooling MACHINE TYPE “2”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4)

1

Water temperature at

Evaporator Inlet

High Pressure High Pressure Water temperature at

Evaporator Inlet

2

Water temperature at

Evaporator Outlet

Water temperature at

Evaporator Outlet

Low Pressure Low Pressure Water temperature at

Evaporator Outlet

Water temperature at

Evaporator Outlet

3

Delivery Temperature Delivery Temperature Delivery Temperature Delivery Temperature Outside Air Temperature

4

Water Temperature at

Freecooling Inlet

Voltage / Current / External

Set-point

Voltage / Current Water Temperature at

Freecooling Inlet

5

Outside Air Temperature Water temperature at

Evaporator Inlet

Voltage / Current / External

Set-point

Voltage / Current

6

Voltage / Current / External

Set-point

Voltage / Current Water temperature at

Evaporator Outlet

Water temperature at

Evaporator Outlet

Delivery Temperature Delivery Temperature

7

High Pressure High Pressure Outside Air Temperature High Pressure High Pressure

8

Low Pressure Low Pressure Water Temperature at

Freecooling Inlet

Low Pressure Low Pressure

6.3.3 DIGITAL OUTPUTS

Chiller unit with freecooling MACHINE TYPE “2”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4)

1

Circulation Pump Circulation Pump Circulation Pump

2

Line Contactor Line Contactor Line Contactor Line Contactor Line Contactor Line Contactor

3

Star Contactor Star Contactor Star Contactor Star Contactor Star Contactor Star Contactor

4

Triangle Contactor Triangle Contactor Triangle Contactor Triangle Contactor Triangle Contactor Triangle Contactor

5

Liquid Solenoid Liquid solenoid C 2 Liquid Solenoid Liquid solenoid C 2 Liquid Solenoid Liquid solenoid C 2

6

Capacity Control Relay 1 Capacity Control Relay 1 Capacity Control Relay 1 Capacity Control Relay 1 Capacity Control Relay 1 Capacity Control Relay 1

7

Capacity Control Relay 2 Capacity Control Relay 2 Capacity Control Relay 2 Capacity Control Relay 2 Capacity Control Relay 2 Capacity Control Relay 2

8

Capacity Control Relay 3 Capacity Control Relay 3 Capacity Control Relay 3 Capacity Control Relay 3 Capacity Control Relay 3 Capacity Control Relay 3

9

Fan 2 Fan 2 Fan 2 Fan 2 Fan 2 Fan 2

10

Antifreeze Heater Antifreeze Heater Antifreeze Heater Antifreeze Heater Antifreeze Heater Antifreeze Heater

11

General Alarm General Alarm General Alarm General Alarm General Alarm General Alarm

12

Fan 1 Fan 1 Fan 1 Fan 1 Fan 1 Fan 1

13

Freecooling ON/OFF Valve Freecooling ON/OFF Valve Freecooling ON/OFF Valve

6.3.4 ANALOGUE OUTPUTS

Chiller unit with freecooling MACHINE TYPE “2”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4) Master (Address 1) Slave (addresses 2/3/4)

1

Speed Controller Speed Controller Speed Controller Speed Controller Speed Controller Speed Controller

2

3-way Freecooling Valve 3-way Freecooling Valve 3-way Freecooling Valve

Loading...

Loading...