Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

31

14 Forced capacity control

Inputs used

• Water temperature at evaporator outlet

• Compressor delivery temperature

• Condensation pressure

Parameters used

• High delivery temperature prevention threshold

• High delivery temperature prevention differential

• High pressure prevention threshold

• High pressure prevention differential

• Antifreeze temperature prevention threshold Antifreeze temperature prevention differential

• Forced selection of compressor at minimum/maximum power

Outputs used

• All compressor capacity control relays

14.1.1 Description of operation

The compressor forced capacity control function prevents the unit from operating in abnormal conditions of pressure, refrigerated water

temperature or condensation temperature, thus preventing any intervention by specific alarms.

A parameter is provided for selecting the compressor operating mode if forced capacity control is enabled. The compressor can be taken to

minimum/maximum power according to the selection when:

• High delivery temperature threshold exceeded

• High pressure threshold exceeded

• Antifreeze temperature threshold exceeded

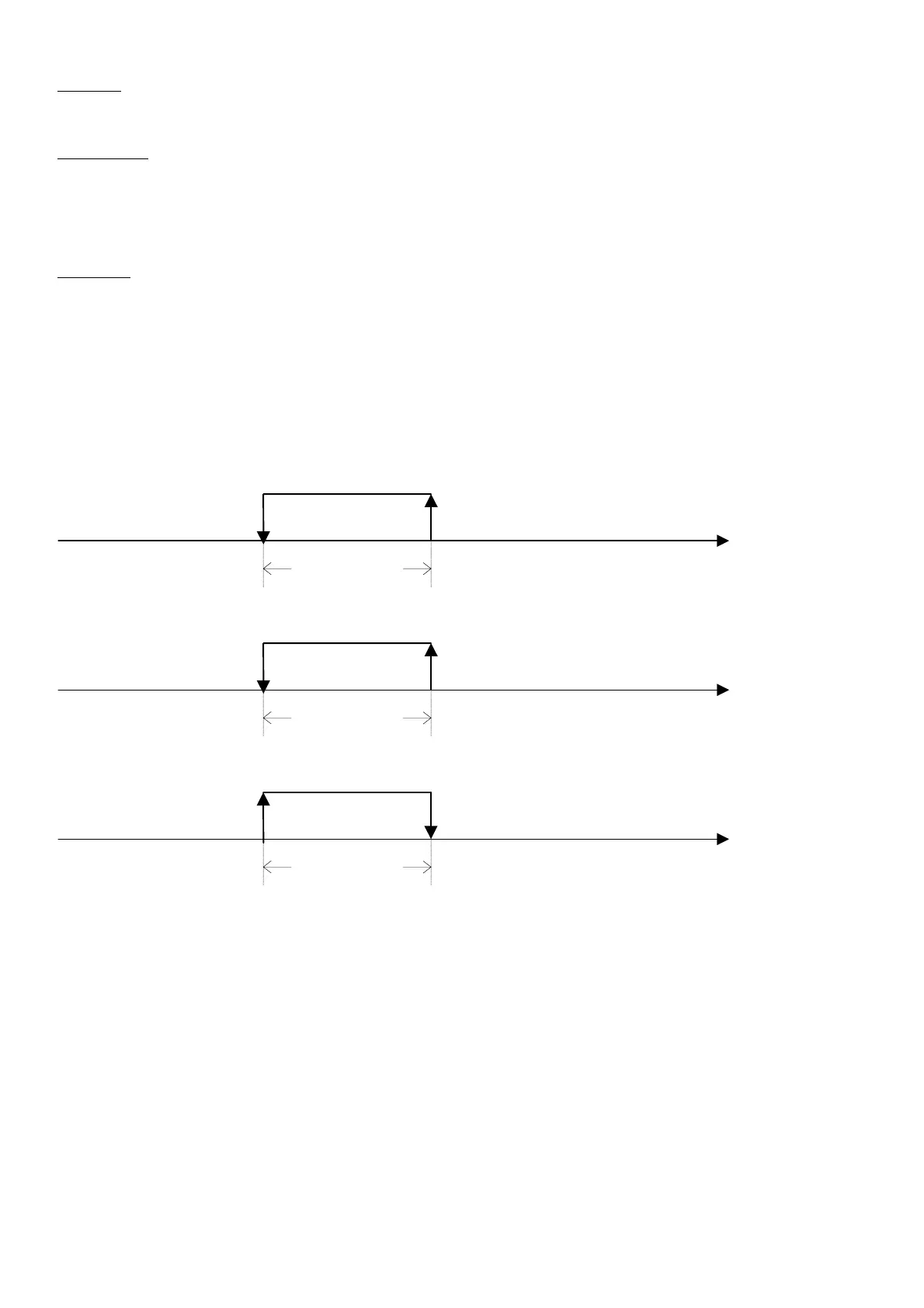

Compressor delivery

temperature

Delivery temperature

threshold

Differential

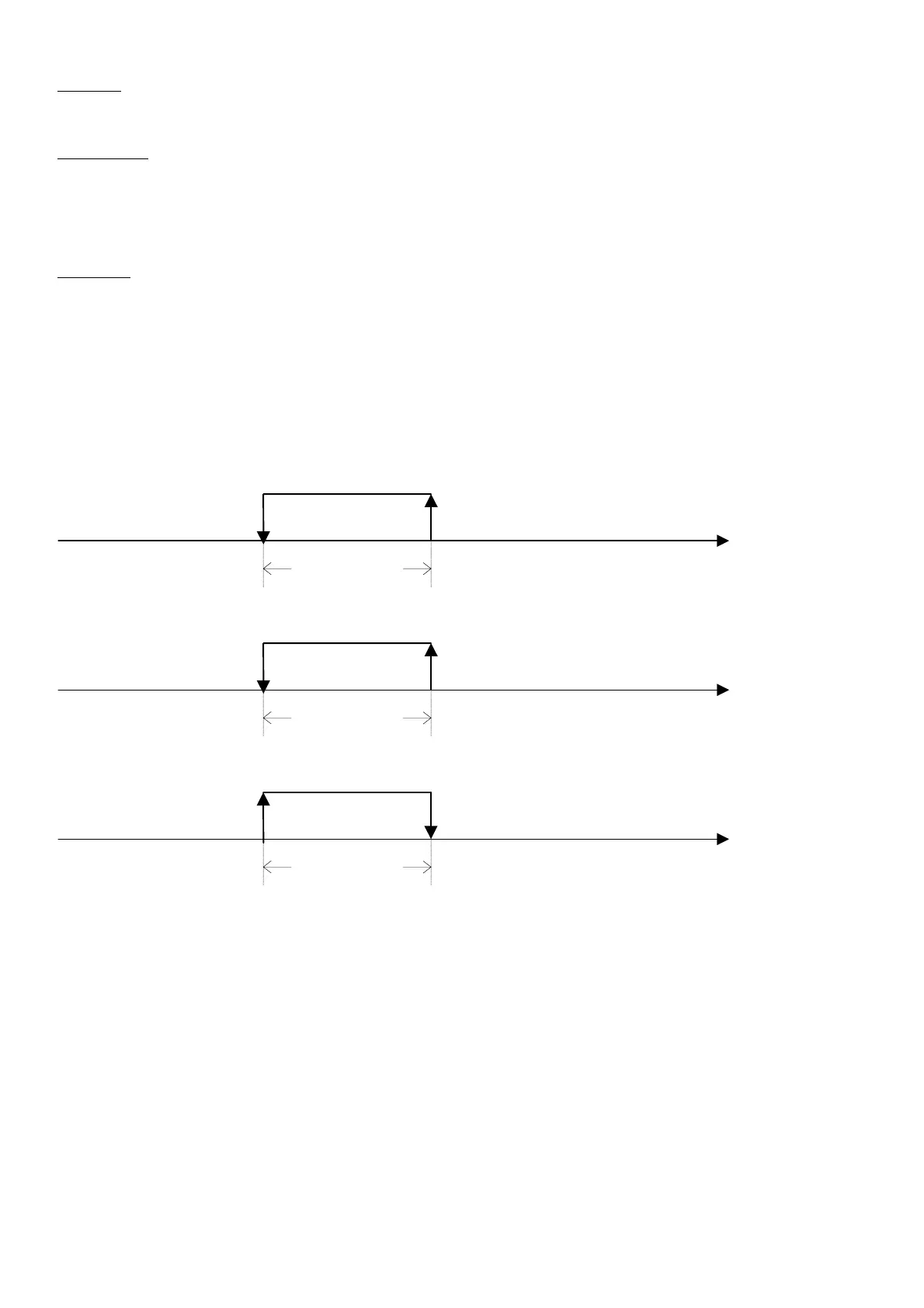

Condensation

pressure

Condensation

pressure threshold

Differential

Evaporator outlet

temperature

Anti-freeze

temperature

threshold

Differential

14.1.2 Compressors with stepped capacity control

For compressors with stepped capacity control, forced capacity control means that the compressor has to operate at minimum or maximum

power according to selection.

14.1.3 Compressors with continuous capacity control.

For compressors with continuous capacity control, forced capacity control means that the compressor has to operate in continuous charging or

discharging mode according to selection.

Loading...

Loading...