Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

32

15 Solenoid-valve management.

Inputs used:

• Compressor delivery temperature

Parameters Used

:

• Solenoid-valve activation threshold

• Solenoid-valve differential

Outputs used :

• Economizer solenoid-valve, oil-cooler, liquid-injection

15.1.1 Description of operation

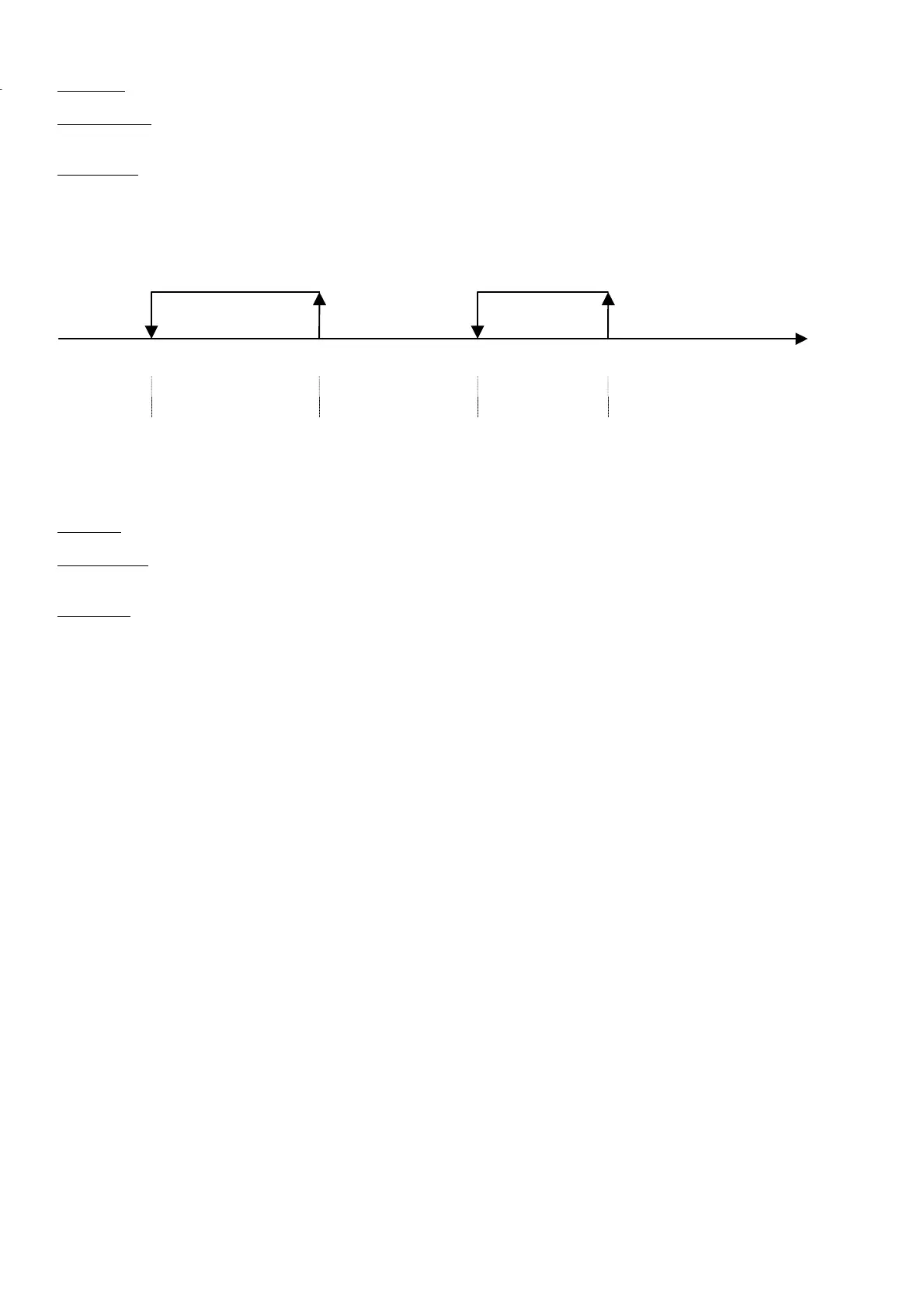

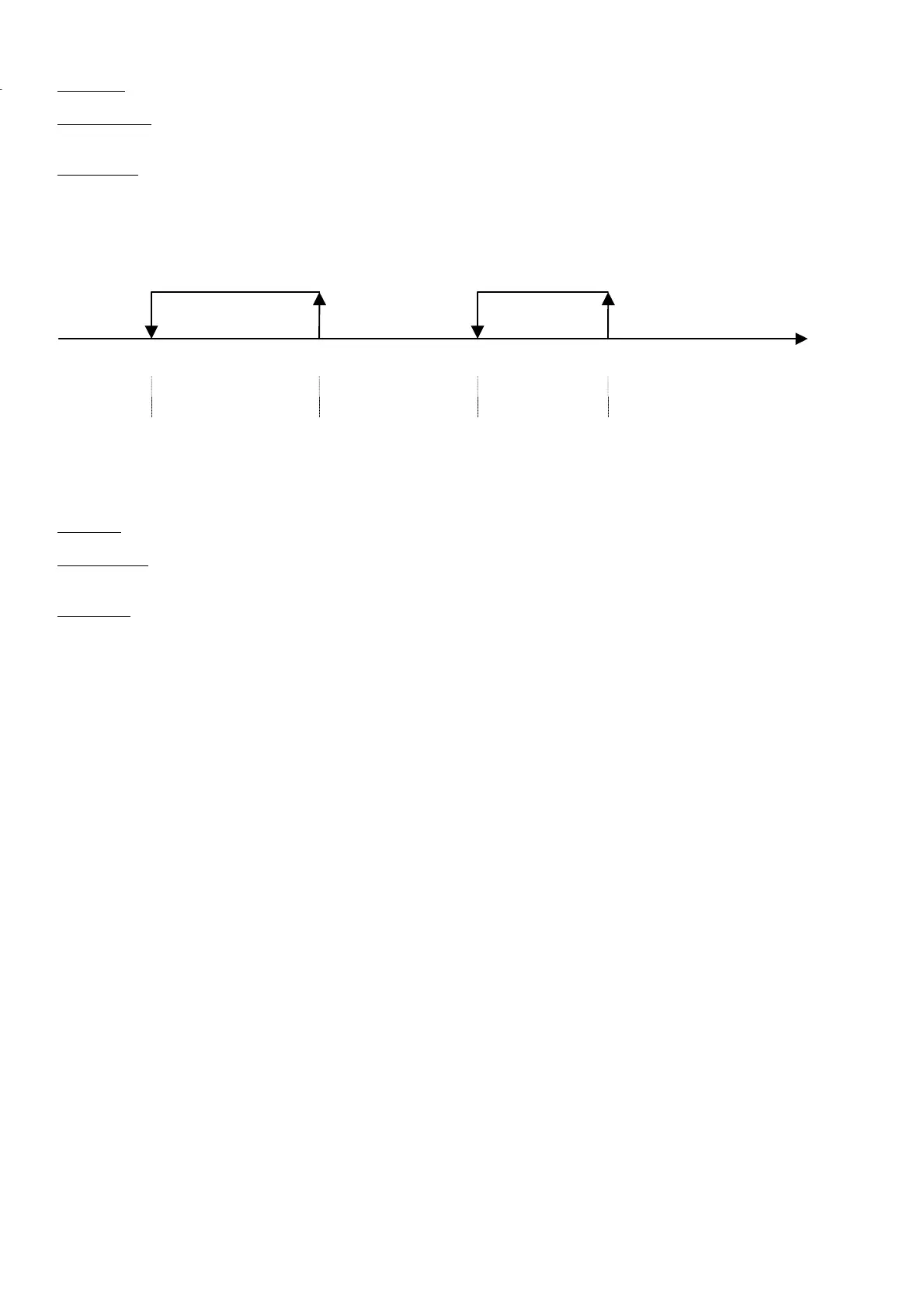

A digital output is provided for controlling an economizer solenoid-valve, oil-cooler and liquid injection. Activation is based on the delivery

temperature values of the compressor read by the probe according to the following graph

Solenoid-valve

activation threshold

Differential

Compressor delivery

temperature

Differential

Delivery Alarm

threshold

16 Pump-down

Inputs used

• Low Pressure Pressure-switch

Parameters used

• Enable pump - down

• Pump - down maximum duration

Outputs used

• Liquid Solenoid

• Windings for compressor Line - Delta - Star

• All compressor capacity control relays

16.1.1 Description of operation

If enabled, pump-down occurs by the thermostat disabling the compressor.

Pump-down duration can be set and can cease due to maximum time or due to the tripping of the high pressure pressure switch.

If any alarm powers down the machine or even just the compressor, the pump-down finishes immediately.

When the pump-down function operates, this forces the compressor to forced capacity control.

For compressors with stepped capacity control, operation at minimum/maximum power is forced.

For compressors with modulating capacity control, continuous discharging/charging of the compressor is forced.

Loading...

Loading...