Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

37

The purpose of this time is to delay the activation of the compressors in order to give Free Cooling sufficient time to reach the steady state

conditions and take the machine's yield to nominal value. Only after this time has elapsed, and with the main thermostat dissatisfied, the

compressors are commanded to operate. If time is set to 0, the function will be disabled.

While the unit is operating, the same parameter is used by Free Cooling control to reassess the machine's working conditions according to the

value measured by the external temperature probe.

A further temperature delta should be set. This identifies a second threshold below which the yield of the Free Cooling battery is so high that it

can fully satisfy the system's thermal load solely through combined operation of valve and fans.

If the compressors are ON, the external temperature falls below "maximum delta" set according to the following relation:

External T. < Free Cooling Input T. – Free Cooling "Maximum Delta"

and this condition continues for a continuous time period equal to the set by-pass time for the compressors. When this time has elapsed, the

compressors will be commanded to OFF followed by a changeover to pure Free Cooling operation to satisfy load requirements with minimum

use of energy.

When the by-pass time for thermostatic control of the compressors has again elapsed, the requests will be re-assessed.

An antifreeze threshold is specified . It is based on the temperature value of external air to protect the heat exchanger when operating in a cold

environment.

If the temperature of external air is lower than the set threshold, the valve controlling water flow inside the Free Cooling exchanger will be

commanded to open, and the main circulation pump will be enabled (if OFF). This pump moves the fluid and prevents the interior of the

exchanger from freezing.

If the valve is a 0-10V type, the degree of opening will depend on the unit's operating status.

• with the machine OFF, opening to 100% of capacity will be commanded

• with the machine ON, opening to 10% of capacity will be commanded

If the valve is of the ON/OFF type, it will always open to maximum value irrespective of the unit's operating mode.

The entire procedure will finish as soon as the external air temperature reaches a fixed hysteresis of 1.0°C with respect to the set threshold.

19.4 Free Cooling disabling conditions

There are two main causes of the closure of the Free Cooling valve: the first depends on the external temperature conditions, and the second on

thermostatic demand.

The Free Cooling valve will close if the Free Cooling conditions stop.

External T. <

Free Cooling Input T. – (Free Cooling Delta) + 1.5°C

The Free Cooling valve will close if the Free Cooling thermostat is satisfied.

For system safety, the reading of the water temperature probe a the evaporator outlet is checked.

According to the set thresholds, the following will be processed: an antifreeze pre-alarm, which will enable any post-heating heaters and totally

disable the Free Cooling devices; and an antifreeze alarm which will totally disable the unit.

Other system safety devices : serious alarm from digital input, circulation pump thermal cutout, failed control probe, failed antifreeze control

probe, evaporator flow-switch alarm, phase monitor alarm. These safety device will totally disabled the unit, and, therefore, stop the Free

Cooling control.

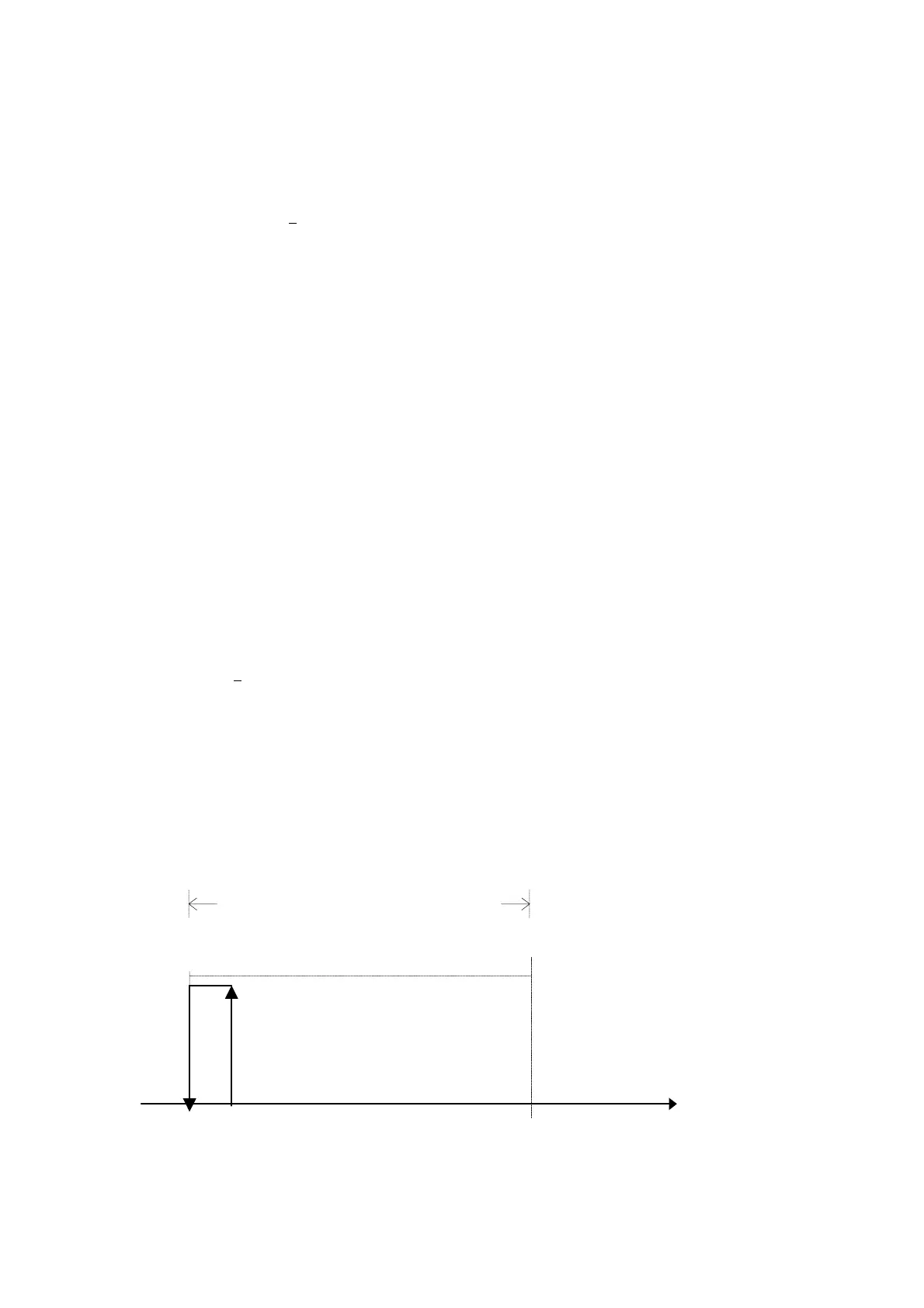

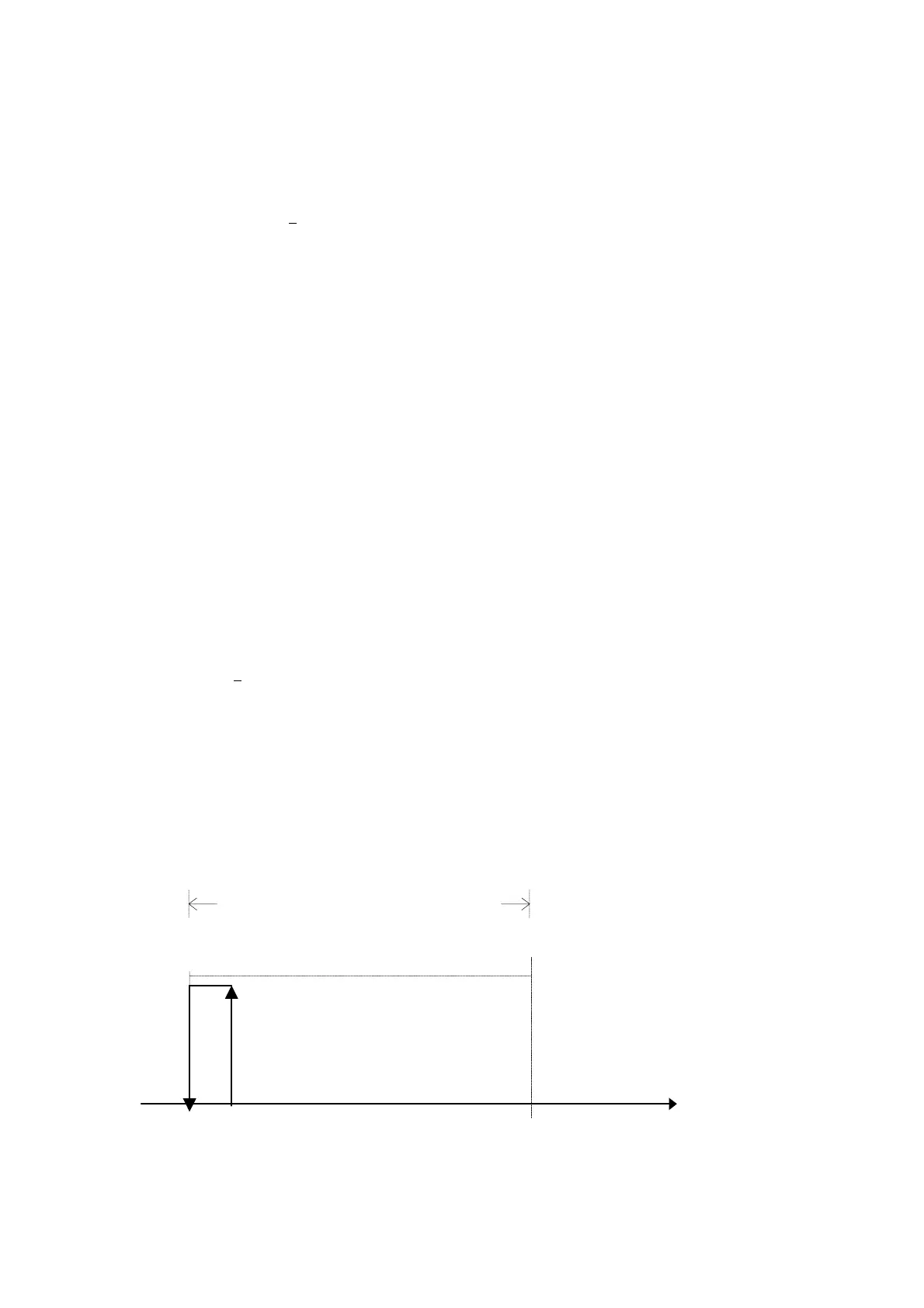

19.5 Free Cooling ON/OFF valve

19.5.1 Proportional control

Evaporator Outlet

Temperature

Free Cooling set point

Free Cooling Differential

Free Cooling

ON/OFF valve

5,0 %

If temperature conditions favour Free Cooling control, the Free Cooling ON/OFF valve will be activated as soon as temperature exceeds the

activation threshold of the individual step, identified by a temperature value of:

Control Set point - Free Cooling Differential +5.0% Free Cooling Differential

The step amplitude is fixed at 5.0% of the set Free Cooling control differential.

Loading...

Loading...