Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

25

11 Types of controlled compressors

11.1 Stepped capacity control

A maximum number of four compressors are managed, with a maximum of four capacity control steps each. Capacity control is achieved by

three relay outputs which, when suitably commanded, short-circuit the refrigerant thrust by the compressor, varying its capacity and, therefore,

the power input into the circuit.

11.1.1 Configuration of stepped capacity control relays

The enabling sequence of the capacity control relays differs for each compressor. Therefore, the software has a facility for configuring the

enabling sequence according to the needs of different compressor manufacturers.

For multi-card systems: as several compressors are housed on the same machine, it is considered that the compressors controlled by each pCO

are perfectly equal and, therefore, the capacity control configuration selected on board the master card also applies to the slave cards.

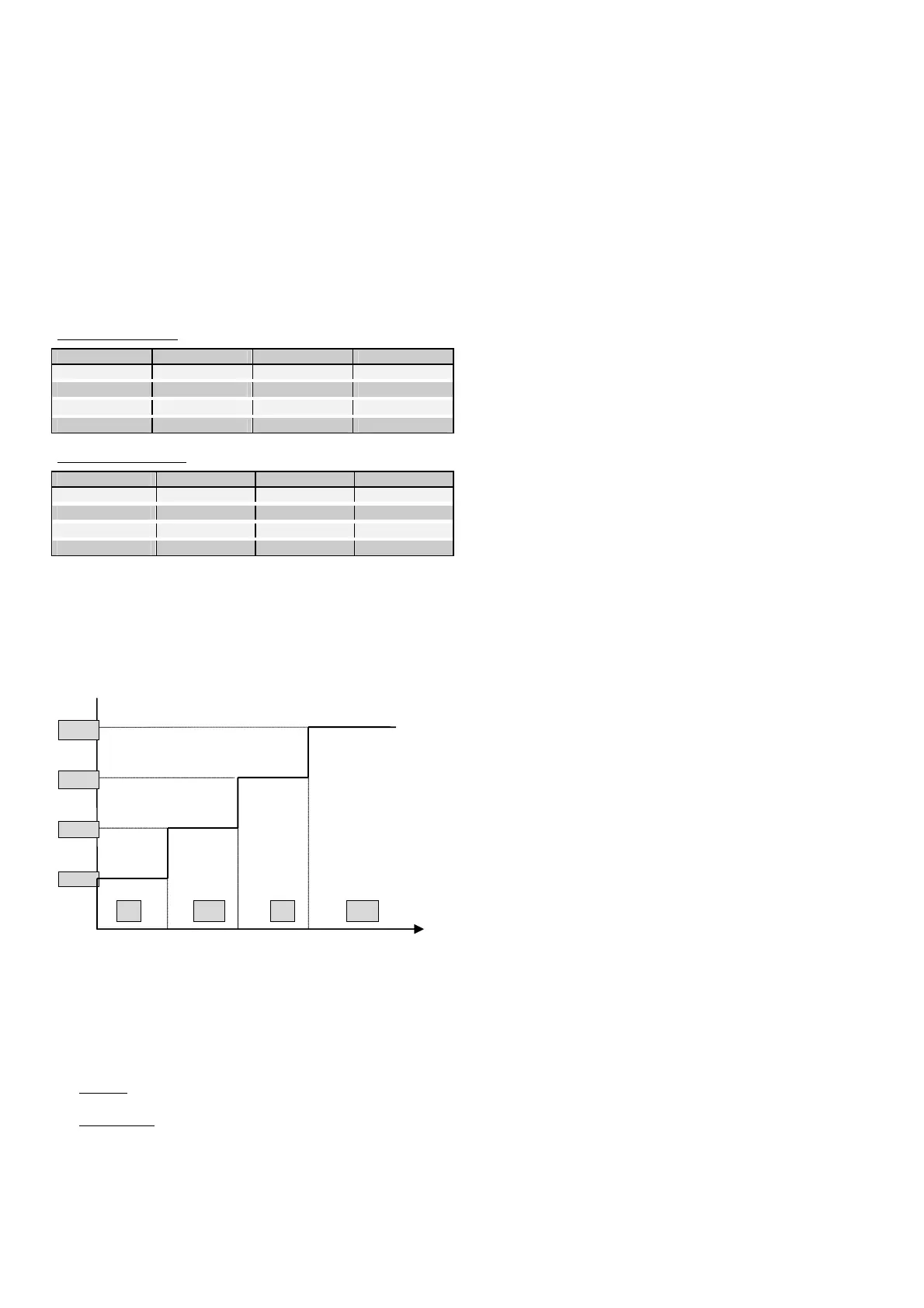

The following table shows examples of the configuration of the dedicated digital outputs for the different power stages entered.

The effective status of the digital output is indicated. The relation between the data in the table and the values set on the display.

Closed = ON Open = OFF

Default configuration

:

% LOAD Relay 1 Relay 2 Relay 3

25%

CLOSED OPEN OPEN

50%

OPEN OPEN CLOSED

75%

OPEN CLOSED OPEN

100%

OPEN OPEN OPEN

Configuration example :

% LOAD Relay 1 Relay 2 Relay 3

25%

OPEN CLOSED CLOSED

50%

CLOSED CLOSED OPEN

75%

CLOSED OPEN CLOSED

100%

CLOSED CLOSED CLOSED

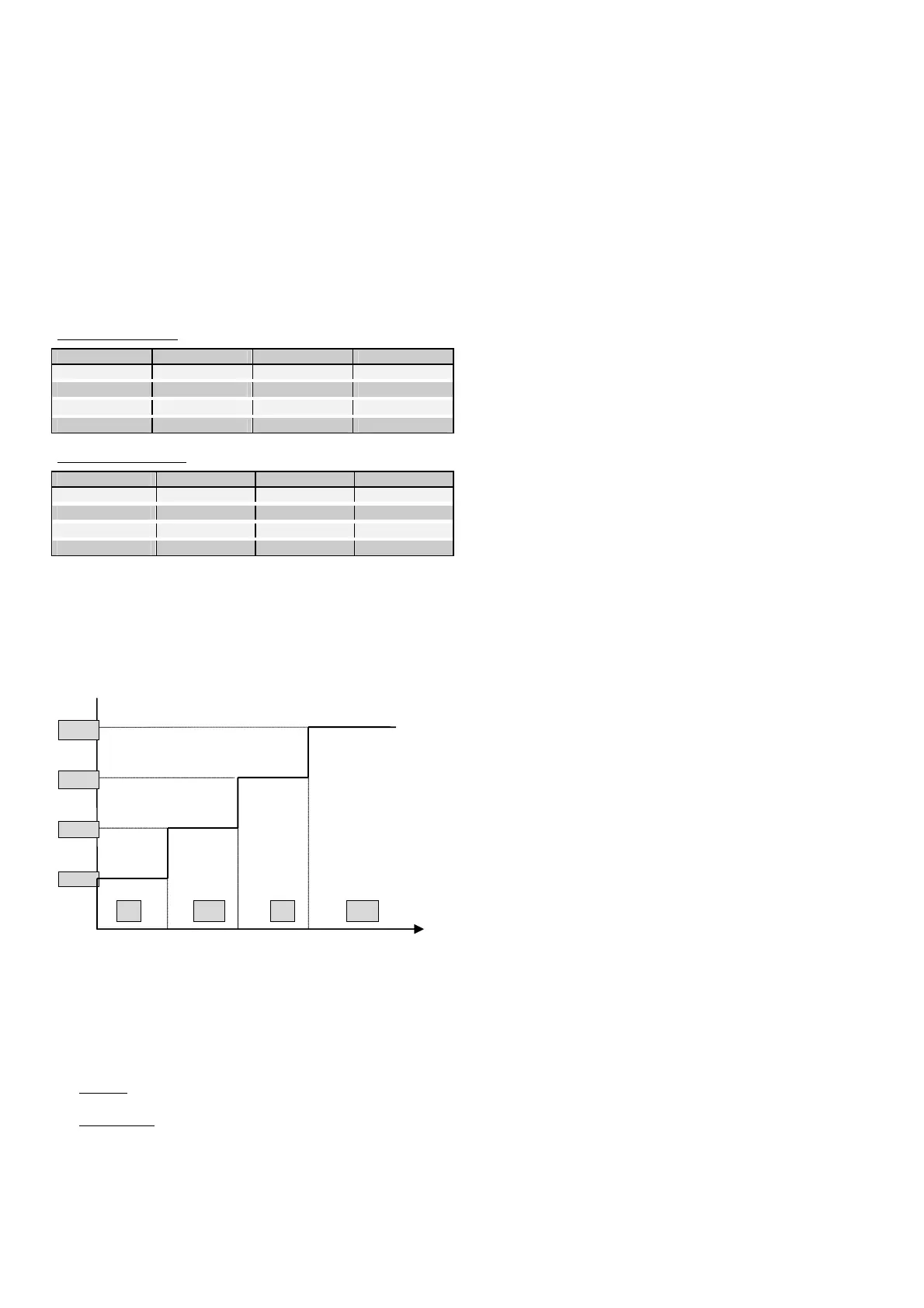

11.1.2 Stepped capacity control times

Delays are specified for capacity control management. These delays can be set when the capacity controls are enabled.

Such delays indicate the minimum operating time of a compressor at a given power stage. If the machine is enabled at maximum level request,

these delays prevent a changeover from power level 0 to maximum level.

Graph of times for capacity control in 4 steps:

T1

T2

T3

25%

50%

75%

100%

T4

11.1.3 Special management of capacity control first stage

A facility is provided for enabling special management of the first stage of capacity control, managing the compressor's special requirements

when it is operating at low power.

In general, the control entails the use of the first capacity control stage only at power-up and if temperature falls below the control set-point.

When controlling the compressor, this type of control uses a reduced power modulation range, between the second and maximum power stages.

Management varies according to whether the compressor is in its starting or disabling stage. In both cases, you are recommended not work at

25% power for too long.

• Starting:

after being started, if the compressor does not receive any thermostatic request for changeover to the second capacity control stage,

the changeover is forced by the software after a time which can be set on the screen (T1).

• Power-down:

if a reduction in the power of the circuit is requested, power is controlled between the maximum and second capacity control

stage. Only if temperature drops below set-point value, the compressor is forced to operate according to the first capacity control stage for

the set time (T1).

This special operating mode is enabled from the screen. If the first capacity control step is not enabled, it is treated as just any step. The

compressor can operate at this power level for an infinite time.

Loading...

Loading...