Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

27

11.4 Continuous capacity control

A maximum number of four compressors are managed, with continuous capacity control.

The compressor's capacity is controlled by two relay outputs, which, when suitably controlled, enable compressor power to be increased or

reduced, varying the capacity of the compression chamber.

Compressor power is controlled by sending impulses to the outputs of the capacity control relays. These impulses command the compressor to

be charged or discharged.

These impulses are at a constant frequency, settable, and of variable duration between two minimum and maximum limits, also settable.

As there is no acquisition regarding the absolute position of the compressor 's capacity control valve, and, consequently, as no direct verification

is possible of the power percentage input in the circuit, a time based control is run. With this control, when a set time threshold is reached, the

compressor is considered fully charged/discharged and thus control of the capacity control impulses is suspended.

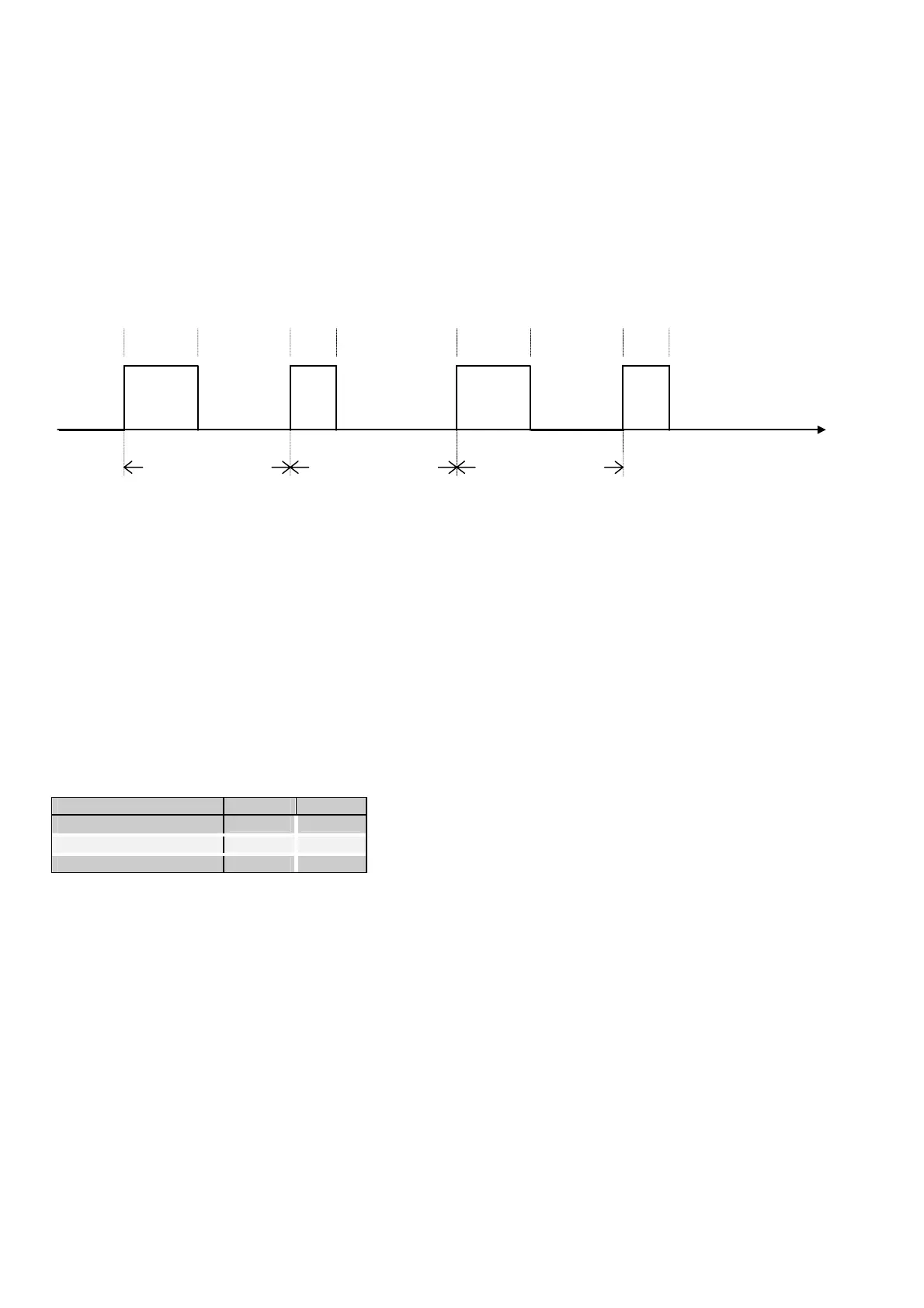

Impulse

calculated

duration

Impulse period

Impulse period

Impulse period

Impulse

calculated

duration

Impulse

calculated

duration

Impulse

calculated

duration

Time [s]

11.4.1 Configuration of continuous capacity control relays

The control method of the capacity control relays differs for each compressor. Therefore, the software has a facility for configuring the enabling

sequence according to the needs of different compressor manufacturers.

For multi-card systems: as several compressors are housed on the same machine, it is considered that the compressors controlled by each pCO

are perfectly equal and, therefore, the capacity control configuration selected on board the master card also applies to the slave cards.

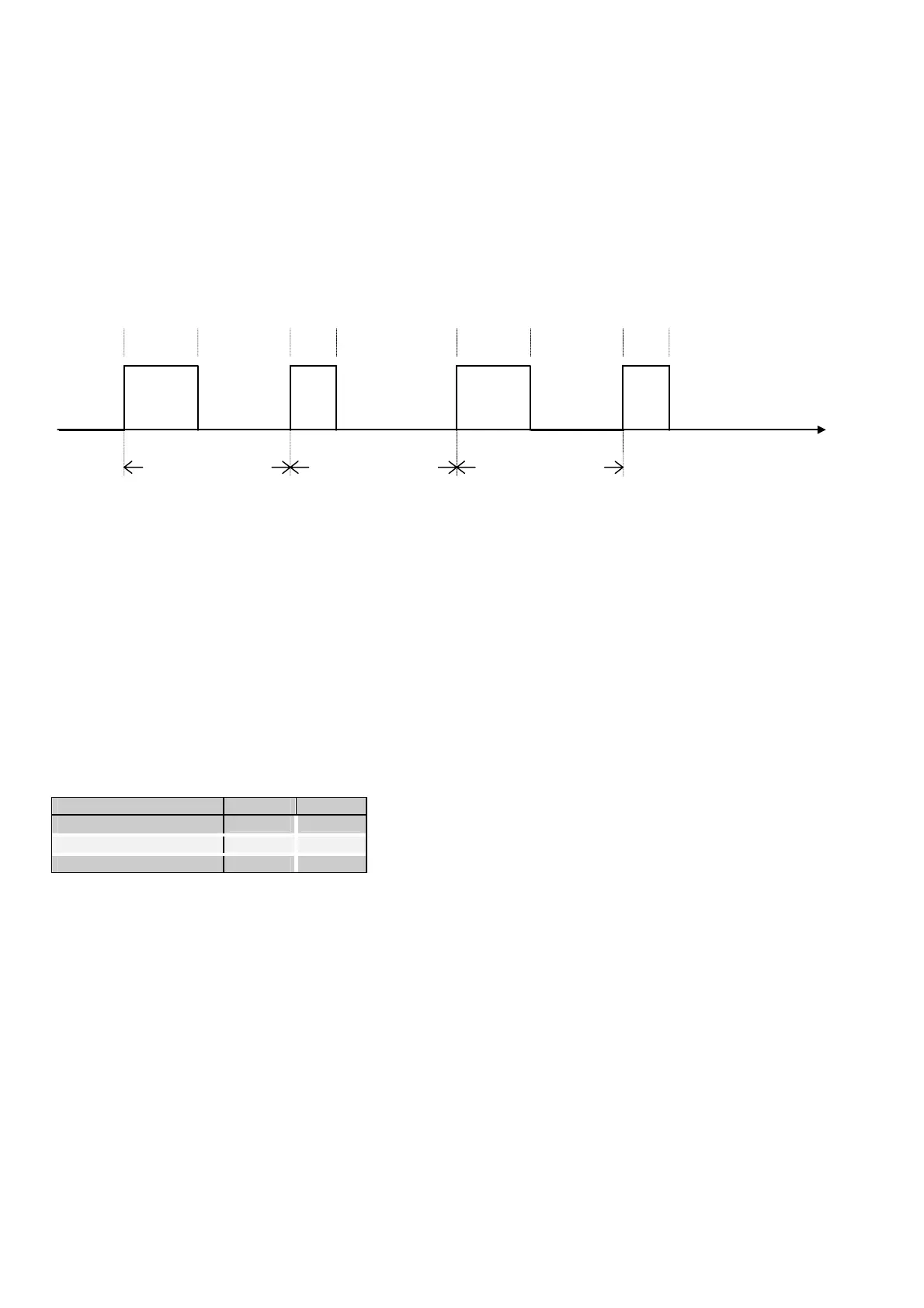

The following table shows examples of the configuration of the dedicated digital outputs for the different power stages entered.

The effective status of the digital output is indicated.

The relation between the data in the table and the values set on the display.

Closed = ON

Open = OFF

Default configuration :

Compressor behaviour Relay 1 Relay 2

Power reduction

CLOSED CLOSED

Power stand-by

OPEN CLOSED

Power increase

OPEN OPEN

The power stand-by configuration is taken on by the outputs when no variation of input power is requested, or if the maximum/minimum

compressor power is reached, or because the water temperature measured by the probe located at evaporator outlet is inside the neutral control

zone.

For compressor charging /discharging, the digital outputs of the pCO card are commanded alternatively according to the stand-by and

charge/discharge configuration, causing the dedicated relay to pulse.

Loading...

Loading...