Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

20

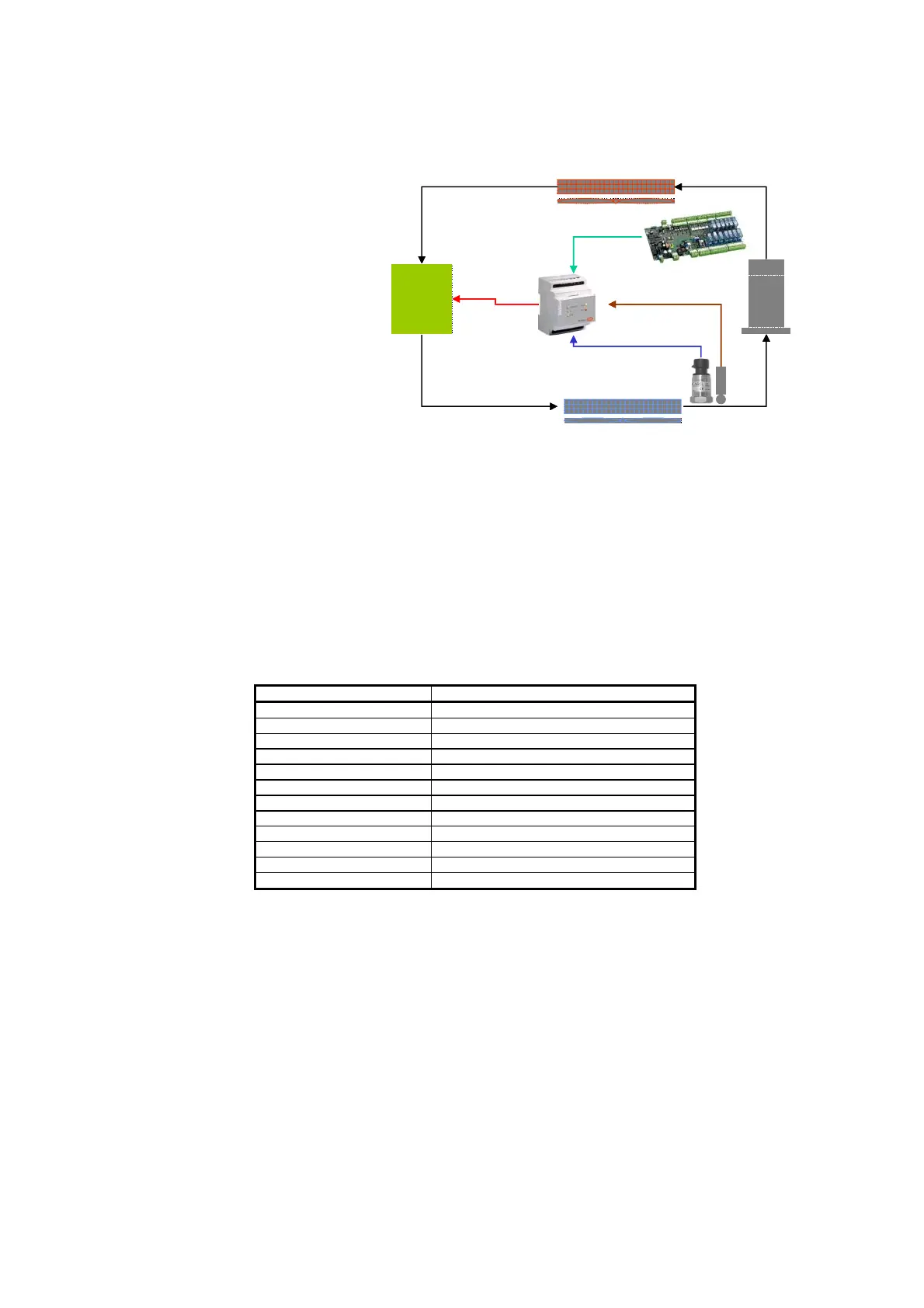

9 ELECTRONIC EXPANSION VALVE

The EV Driver module for piloting the electronic expansion valves (EEV) for the pLAN network, makes it possible to control intake

superheating to enable the refrigerating unit to operate more efficiently and with greater versatility.

We say efficiently, because by improving and stabilising

the flow of refrigerant to the evaporator, we increases the

system's overall performance, while guaranteeing safety

(low pressure pressure switch less frequently tripped,

fewer returns of liquid refrigerant to the compressor,…).

Furthermore, if the EEV is correctly sized, use of

condensation pressure (or evaporation pressure,) either

floating or at low set point, considerably increases the

system's efficiency, while ensuring lower energy

consumption and greater refrigerating yield. It is versatile,

because the electronic expansion valve makes it possible

to serve refrigerating units with a lower refrigerating

capacity and in operating conditions which may differ

considerably from each other.

Using an expansion valve entails the installation not

only of the EVDriver and the expansion valve itself,

but also of a temperature sensor and a pressure

transducer, both located on the refrigerating side at the

end of the evaporator (on the compressor's intake

pipe). Consult the following diagram for a better

understanding of the system's typical lay-out.

The priorities to be considered for optimal control of the refrigerating system: obtaining a high, constant refrigerating yield rather than very low,

stable superheating.

The heart of the control is a PID control with settable coefficients for superheating.

These are the additional controls: LOW (Low superheating with integral time and adjustable threshold)

LOP (Low evaporation pressure, operating in transients only, with integral time and

adjustable threshold)

MOP (High evaporation pressure with integral time and adjustable threshold)

HiT cond (High condensation pressure, enablable only with the condensation pressure probe

read by pCO, with integral time and adjustable threshold)

The parameters table describes the control parameters with thresholds and default values. The table below explains the meaning of the VALVE

TYPE parameter (see screens F1- F2):

PARAMETER VALUE TYPE OF CORRESPONDING VALVE

0 Alco EX5 – EX6

1 Alco EX7

2 Alco EX8

3 Sporlan SEI 0.5 - 11

4 Sporlan SEI 25

5 Sporlan SEI 50 – SHE 250

6 Danfoss ETS 50

7 Danfoss ETS 100

8 ---

9 Carel E2V**P

10 Carel E2V**A

11 Custom (other type of valve)

9.1 DRIVER PARAMETERS

In this section, we shall explain the essential parameters of greatest interest for setting up the driver. The screen code (see chap. "PARAMETERS

LIST") is used (in brackets) to describe these parameters, in order to help you find the appropriate parameter.

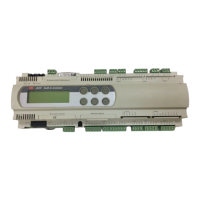

Each pCO* card manages a maximum of two drivers. As they have the same configuration, this section illustrates the first driver's configuration

only.

9.1.1 Valve Type and battery presence (F0)

The type of valve and battery presence are set on this first screen. These are the possible valves:

• Alco (EX5, EX6, EX7, EX8)

• Sporlan (SEI 0.5, SEI 1, SEI 2, SEI 3.5, SEI 6, SEI 8,5, SEH 100, SEH 175, SEH 250)

• Danfoss (ETS50, ETS100)

• Carel E2V

• Custom valve (if none of the valves described above are the one used by the user).

9.1.2 EEV circ. percentage ratio (F1)

This indicates the ratio, as a percentage, between the maximum refrigerating capacity of the circuit controlled by the EVDriver and the capacity

obtainable through maximum opening of the expansion valve, under the same operating conditions. Operating conditions are all the system variables

which influence the refrigerating yield of both the system and the valve (condensation temperature, subcooling, superheating, loss of load,….).

Condensor

EEV

Evaporator

Compressor

T probe

P probe

Motor

connection

pLAN

EEV

Evaporator

T probe

P probe

Motor

connection

pLAN

Loading...

Loading...