51

6 - APPLICATION DATA

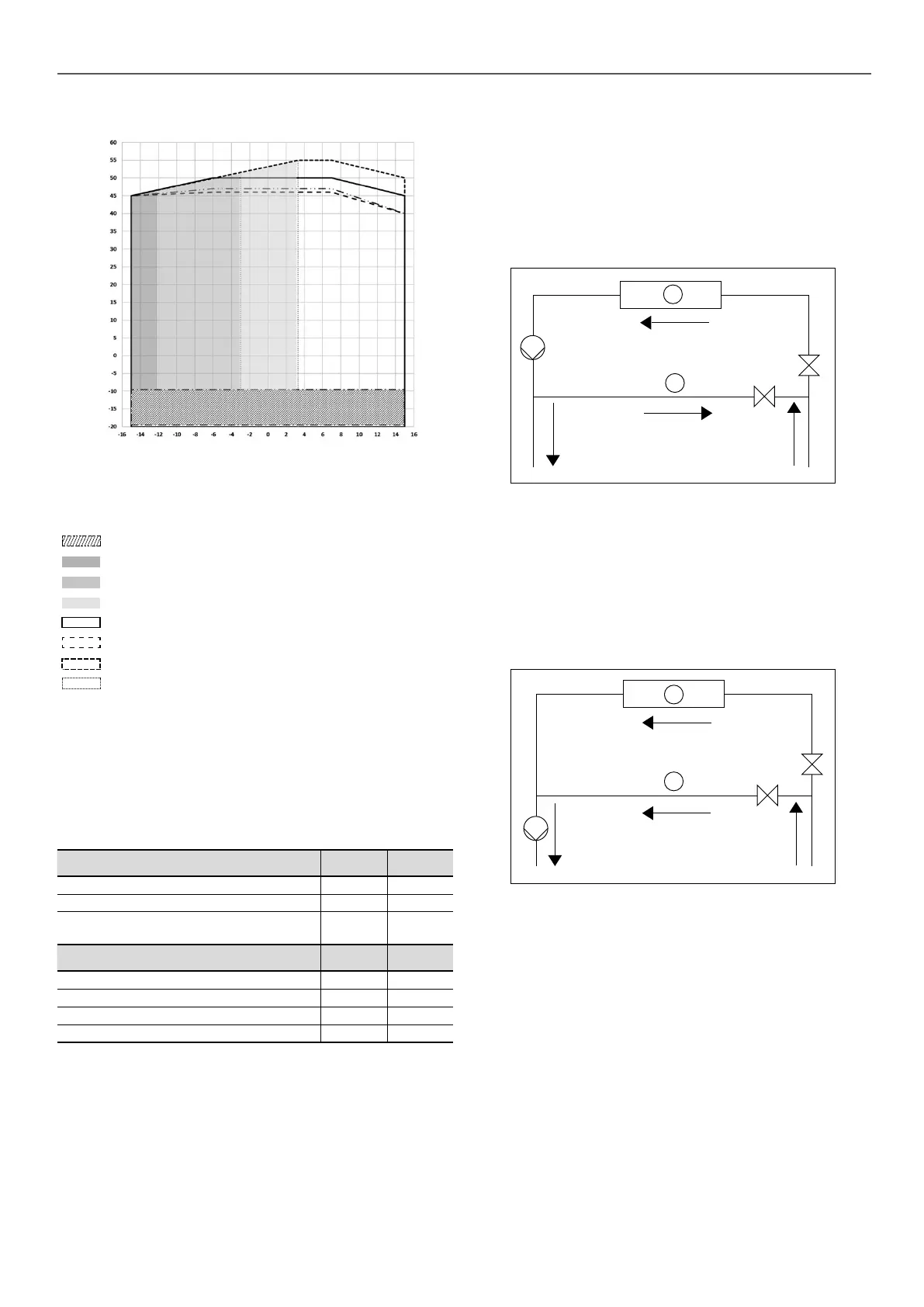

6.1 - Operating range

Evaporator Leaving Water Temperature (°C)

Air inlet temperature (°C)

Low brine

Medium brine

Light brine

NOTE

Ranges given as a guide using ethylene glycol for an evaporator ΔT = 3K. Refer

to the electronic catalogue.

Winter operation option (included in standard for 30XBE & 30XBP ranges)

Low temperature brine, (-15°C ethylene glycol / -10°C propylene glycol)

Medium temperature brine, (-12°C ethylene glycol / -8°C propylene glycol)

Light temperature brine, (-3°C ethylene glycol / 0°C propylene glycol)

Full load - 30XB- range

Full load - 30XBE/P ranges

Full load - OPT 15LS(+)

Part load

Power factor correction option (option/QM 231) available for an inlet air

temperature up to +45°C

For operation in pure water at an inlet air temperature below 0°C, the frost

protection (option_41A or 41B) must be provided

ATTENTION: Option 28 (Winter operation)

If the outside temperature is below -10 °C and the unit has

been switched o for more than 4 hours, it is necessary to

wait 2 hours after the unit has been switched on again to allow

the frequency converter to warm up.

Water heat exchanger Minimum Maximum

Entering temperature at start-up °C - 45

(1)

Leaving temperature during operation °C 3,3 15

Entering/leaving water temperature

dierence

K 2,8 10

Condenser air temperature Minimum Maximum

Storage -20 68

Operation, standard unit -10 55

(2)

With winter operation option (option 28) -20 55

(2)

With Low noise option (option 15LS) -10 52

(2)

Note: If the air temperature is below 0°C, a glycol/water solution or the frost

protection option must be used.

Note: If the leaving water temperature is below 4°C, a glycol/water solution or

the frost protection option must be used.

(1) Based on the installation type and the air temperature

(2) Part load, depended of sizes & leaving water temperature

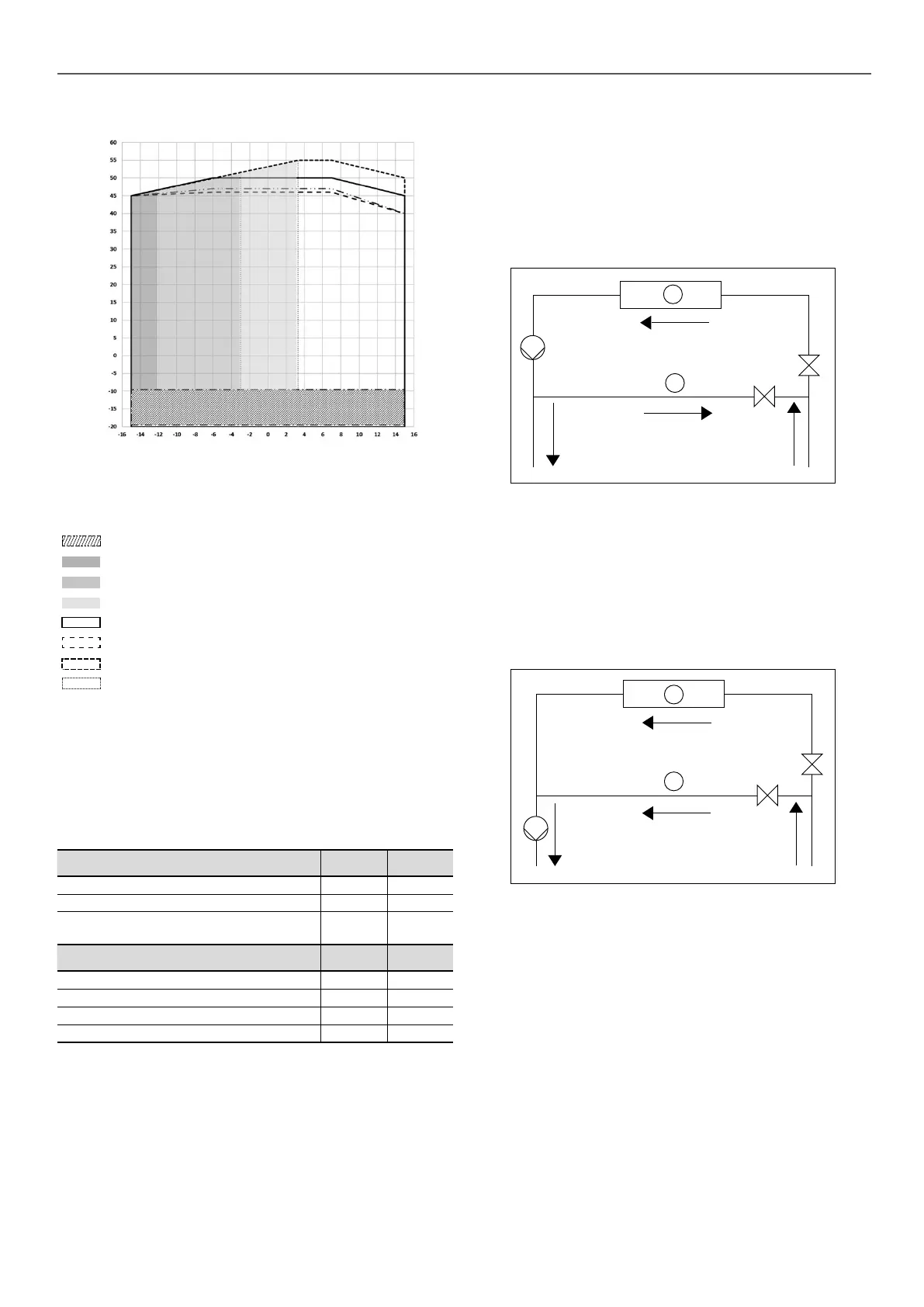

6.2 - Minimum chilled water ow (units without

hydraulic module)

The minimum chilled water ow is shown in the table on the next

page. It is determined in order to allow sucient exchange and

preent the risk of excessive fouling. If the system ow is less than

this, the evaporator ow can be recirculated, as shown in the

diagram.

For minimum chilled water ow rate

1

2

1 Evaporator

2 Recirculation

6.3 - Maximum chilled (units without hydraulic

module)

The maximum chilled water ow is shown in the table on the next

page. If the system ow exceeds the maximum value, it can be

bypassed as shown in the diagram.

For maximum chilled water ow rate

1

2

1 Evaporator

2 Bypass

6.4 - Variable ow evaporator

Variable evaporator ow can be used in standard 30XB(E/P)

chillers. The chillers maintain a constant leaving water temperature

under all ow conditions. For this to happen, the minimum ow

rate must be higher than the minimum ow given in the table of

permissible ow rates and must not vary by more than 10% per

minute.

If the ow rate changes more rapidly, the system should contain

a minimum of 6.5 litres of water per kW instead of 3.25 l/kW.

Loading...

Loading...