72

12 - MAJOR SYSTEM COMPONENTS AND OPERATION DATA

5. For water-cooled units, stop the circulation of the secondary

circuit to the condenser in order to stop the condensation and

cause the increase in pressure ( this operation is managed by

the control on air-cooled machines)

6. Record the trigger value

7. C heck that both HPS were triggered

If both HPS have tripped, go to step 10

If only one of the HPS has tripped,go to step 8

8. Replace the triggeredg HPS with another system whose trigger

value is adequate .

Alternatively, an emergency stop button can be installed.

9. Repeat steps 2 to 6

10. Check if the trigger values are correct

The release values should be between -1 .5 /+0.5 bars of

nominal values indicated on the unit.

11. Reset all alarms

12. reset all HPS

Note: Access to the maintenance functions can be protected

by a password. Contact your dealer or the manufacturer’s

service department for more information.

For step 8 , the electrical disconnection of the triggered HPS

and its substitution must be performed in an environment

with live parts .All the procedures and authorization provided

for this type of intervention must be respected.

The type of connector must be WAGO 231-302 or equivalent.

12.4 - Condensers

30XB coils are all-aluminium micro-channel condensers. Optional

coils with internally grooved copper tubes with aluminium ns are

also available (options 254 and 255).

12.5 - Fans

The fans are axial Flying Bird fans equipped with rotating shroud

and made of composite recyclable material. Each motor is xed

with transverse supports. The motors are three-phase, with

permanently lubricated bearings and insulation class F (level IP55).

According to the Regulation No. 327/2011 implementing Directive 2009/125/EC with regard to ecodesign requirements for fans driven

by motors with an electric input power between 125 W and 500 kW.

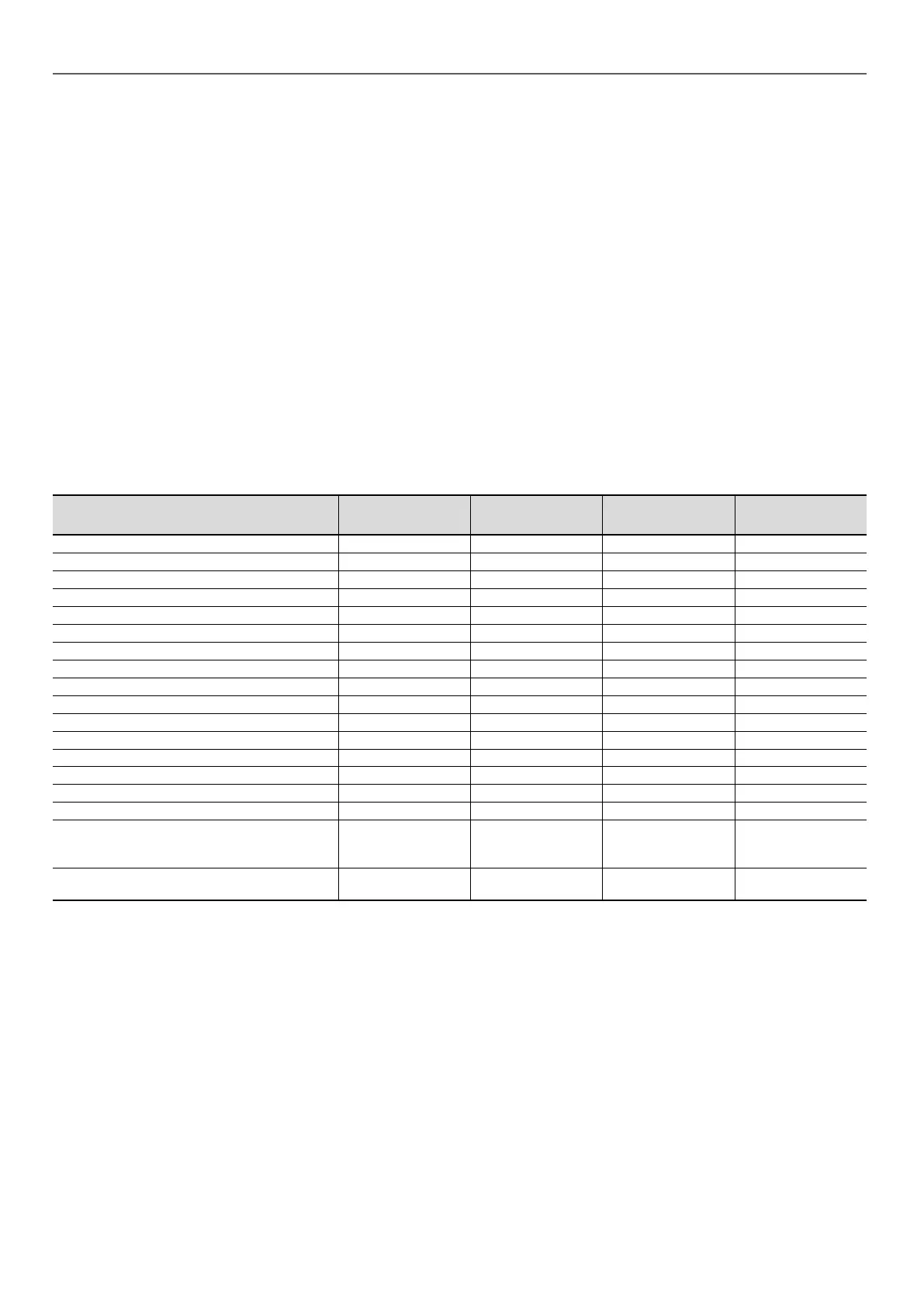

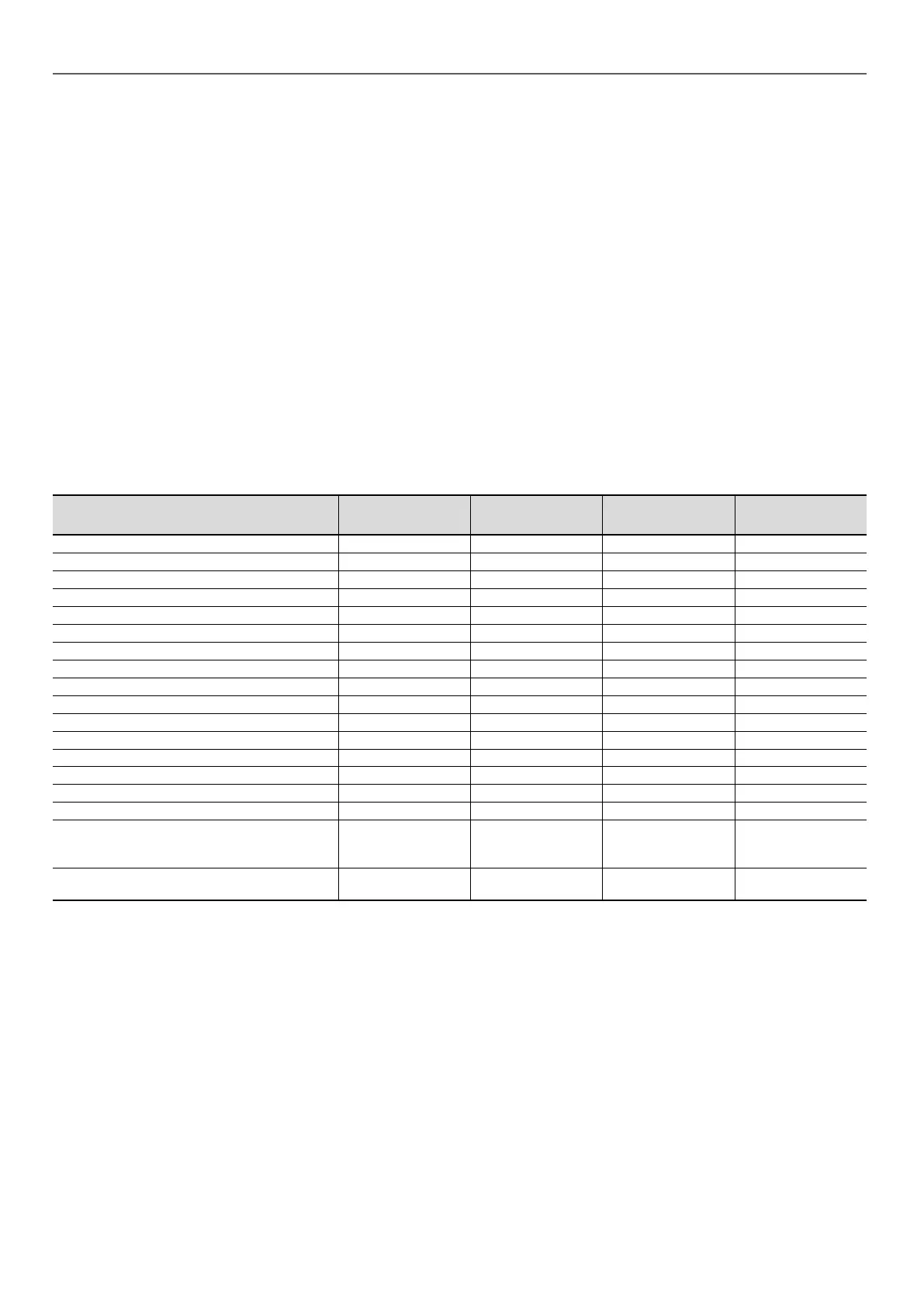

30XB 30XB Standard 30XB Option 15LS

30XB- Option 17 &

30XBE

30XBP

Overall eciency % 38,7 35,3 40,1 47,3

Measurement category A A A A

Aciency category static static static static

Target eciency level ERP2015 N(2015) 40 N(2015) 40 N(2015) 40 N(2015) 40

Eciency level at optimum eciency point 43,3 42,1 44,6 52,2

Variable speed drive NO NO YES YES (embedded)

year of manufacture See label on the unit See label on the unit See label on the unit See label on the unit

Fan manufacturer Simonin Simonin Simonin Simonin

Motor manufacturer Leroy Somer Leroy Somer Leroy Somer EBM Papst

Fan PN 00PSG002630700 00PSG002630700 00PSG002630700A 00PSG002630700

Motor PN 00PPG000558400A 00PPG000558500A 00PPG000558700A 00PSG002696800A

Nominal power of the motor kW 1,90 0,85 1,96 1,68

Flow rate m

3

/s 4,22 3,1 4,22 4,24

Pressure at optimum energy eciency Pa 174,2 96,7 174,2 174,6

Nominal speed rpm 949 710 948 959

specica ratio 1,002 1,002 1,002 1,002

Relevant information to facilitate the

disassembly, recycling or removal of

the product at the end of life

See the maintenance

manual

See the maintenance

manual

See the maintenance

manual

See the maintenance

manual

Relevant information to minimise the

impact on the environment

See the maintenance

manual

See the maintenance

manual

See the maintenance

manual

See the maintenance

manual

Loading...

Loading...