79

14.4 - Tightening torques for the main electrical

connections

14.4.1 - Tightening torques for the main electrical

connections

Component

Designation

in the unit

Value

(N.m)

Screw on bus bar, customer connection

M8 - 18

M10 L1 /L2 /L3 30

Soldered screw PE, customer connection

(M12)

PE 70

Tunnel terminal screw, compressor

contactor

Contactor 3RT103_

Contactor 3RT104_ 5

Contactor 3RT105_ 11

Contactor 3RT106_ KM_ 21

Nut on compressor contactor deck

M8 for contactor 3RT105_ 18

M10 for contactor 3RT10_7 KM_ 30

Tunnel terminal screw, current transformer

Size 2 (3RB2956_) 11

Size 3 (3RB2966_) TI_ 21

Nut on current transformer deck

M8 18

M10 TI_ 30

Compressor earth terminal in the power

wiring control box

Terminal M8 Gnd 30

Compressor phase connection terminals

M12 25

M16 EC_ 30

Compressor earth connection Gnd sur EC_ 25

Tunnel terminal screw, disconnects

3RV1011_

QF_ /QM_ 1

Tunnel terminal screw, hydronic pump

contactor

Contactor 3RT101_ KM90_ 1

Contactor 3RT102_ 2,2

ATTENTION: The tightening of the connections at the

compressor terminals requires special precautions. Please

refer to the chapter below.

14.4.2 - Connection precautions for the compressor

power terminals

These precautions must be applied during an intervention that

requires the removal of the power conductors connected to the

compressor supply terminals.

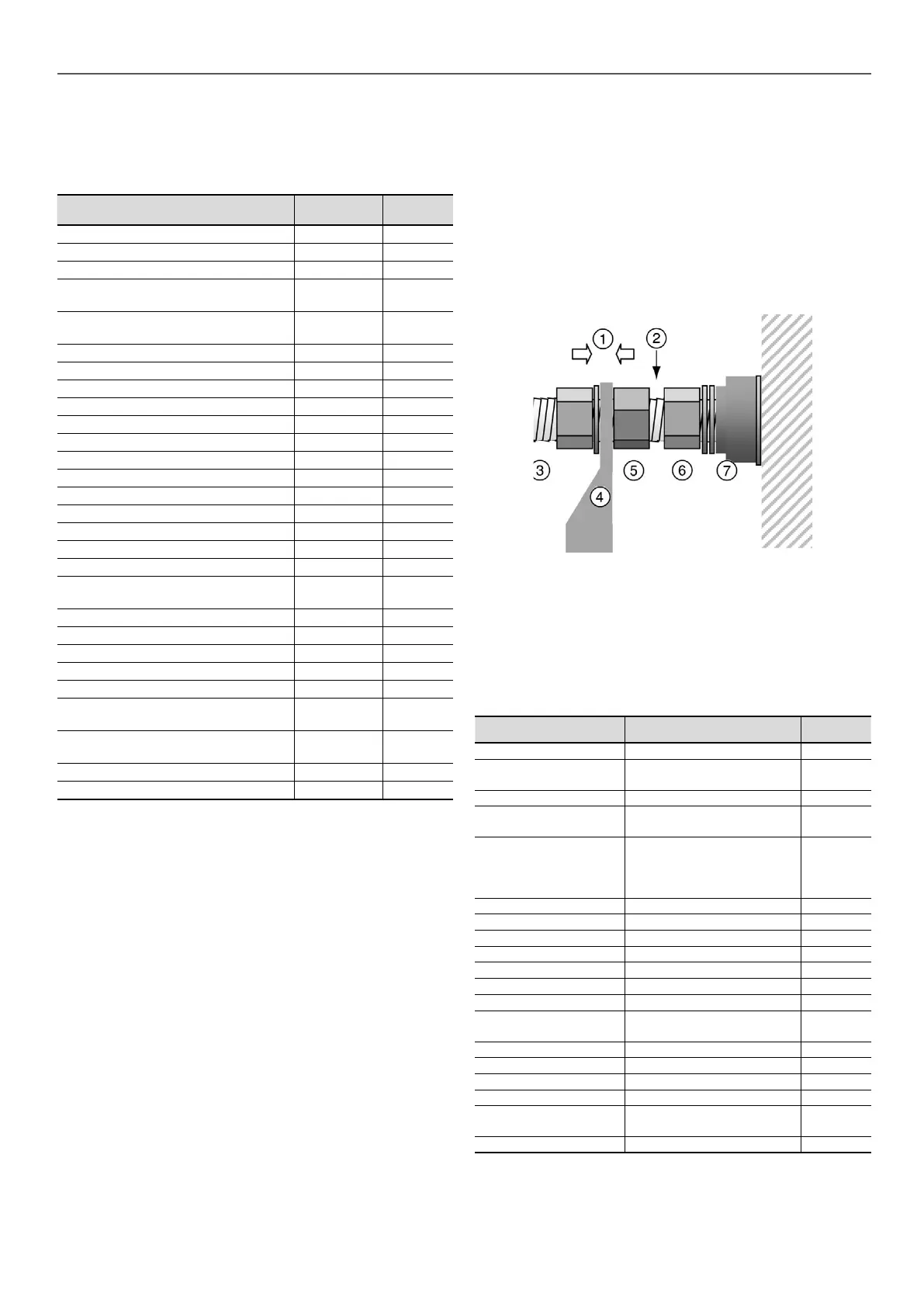

The tightening nut of terminal (6) supporting the isolator (7) must

never be loosened, as ist ensures terminal tightness and

compressor leak tightness.

The tightening of phase lug (4) must apply the torque between counter

nut (5) and tightening nut (3): During this operation a counter-torque

must be applied at counter nut (5). Counter-nut (5) must not be in

contact with the tightening nut of terminal (6).

1. Torque application to tighten the lug

2. Avoid contact between the two nuts

3. Lug tightening nut

4. Flat lug

5. Counter-nut

6. Terminal tightening nut

7. Isolator

14.5 - Tightening torques for the main bolts and

screws

Screw type Use

Value (N.m)

(N·m)

Metal screw D = 4,8

Condensing module, housing

supports

4,2

Metal screw D = 6,3 Plastic volute & grill 4,2

Screw H M8

Condensing module,

compressor xing

18

Taptite screw M10

Condensing module, chassis

- structure xing, control box

xings, compressor xings, oil

separator xing

30

Taptite screw M6 Piping support, cowling 7

Screw H M8 Piping clip 12

Screw H M6 Piping clip 10

Nut H M10 Compressor chassis 30

Nut H M10 Hydraulic pump chassis 30

Screw H M8 Filter drier cover 35

Screw H M12 Economiser port ange 40

Screw H M16

Oil separator anges, suction

anges

110

Screw H M16 Heat exchanger water boxes 190

Screw H M20 Suction anges 190

Nut 5/8 ORFS Oil line 65

Nut 3/8 ORFS Oil line 26

Nut H M12/M16

Victaulic collars on suction

piping

60/130

Self-locking Nut M16 Compressor xing 30

ATTENTION: The tightening of the connections at the

compressor terminals requires special precautions. Please

refer to the chapter below.

14 - STANDARD MAINTENANCE

Loading...

Loading...