chapter 7000

page 10

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

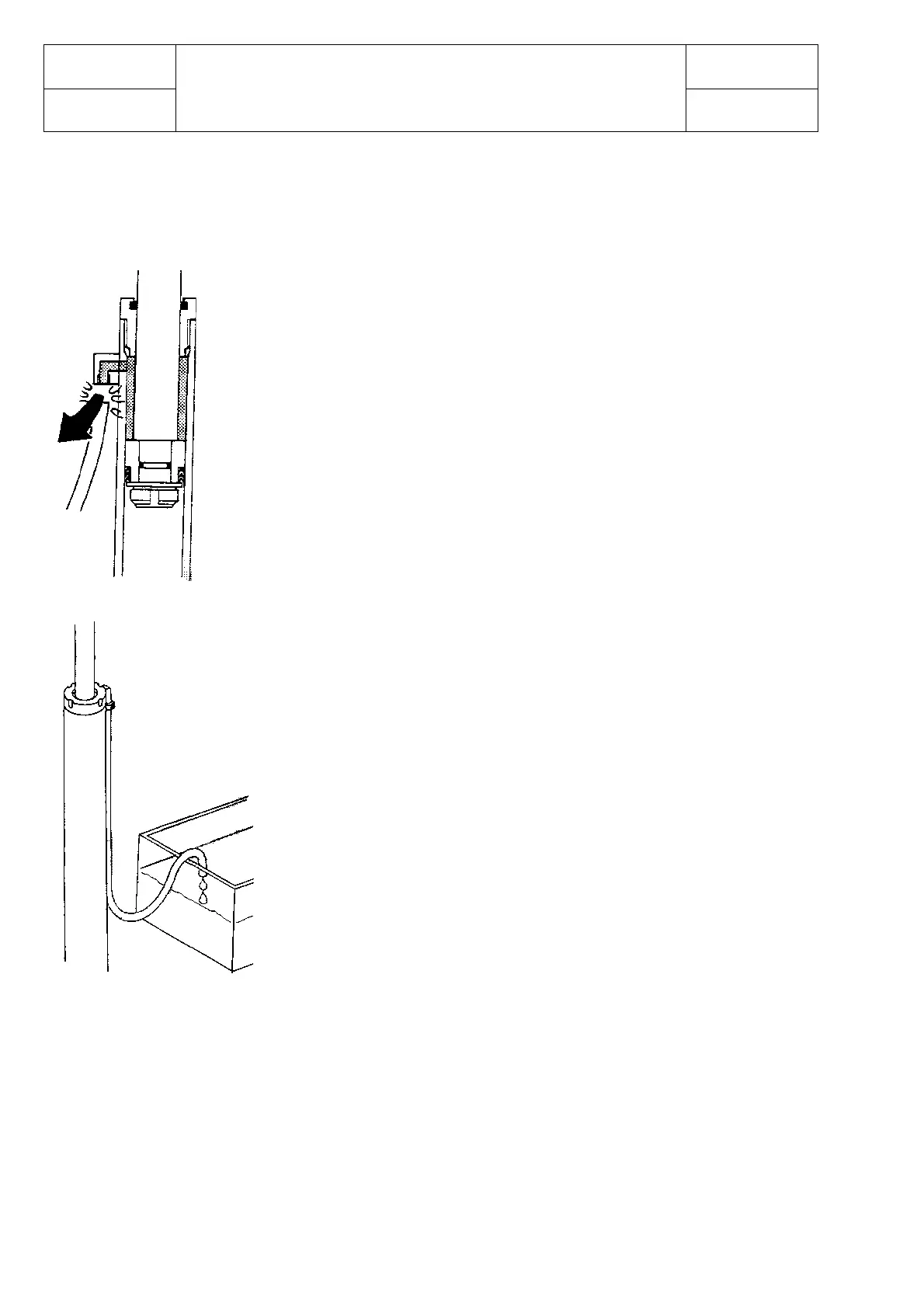

Fig. C

1

ST

CHECK

Remove the drain pipe from the cylinder (fig. C)

Lift the cylinder some times to end stroke, so as to discharge any oil

residual.

Put a load on the forks and lift it by at least 200 mm.

After 10 minutes, measure the amount by which the load has lowered.

A drop of a few millimetres is quite normal, as in the distributor there

are always some leakages.

Now, lift the cylinder to its end stroke, if no oil leaks from the drain

pipe coupling, it means that the load lowering is only due to the leakages

on the distributor.

In the presence of leakages, it will be necessary to replace the seal.

Should this be the case, inspect the cylinder liner.

2

nd

CHECK

(To be carried out if the 1

st

inspection has been successful and after

seal replacement).

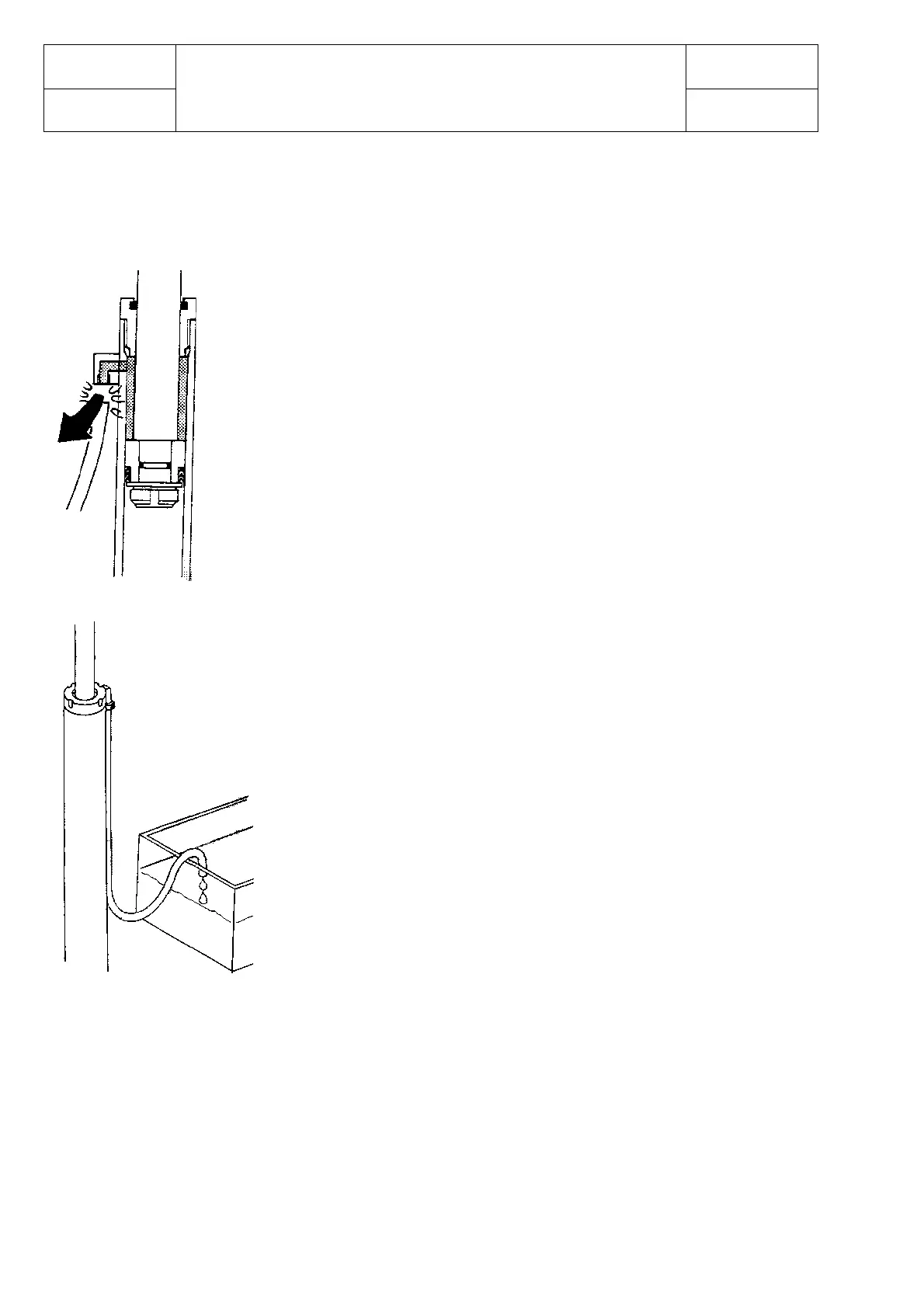

Remove the drain pipe from the cylinder.

Lift the cylinder some times to end stroke, so that all the possible

remaining oil is discharged.

Put a load on the forks. Lift and lower it for 10 minutes, making sure

that the limit stop is never reached.

Lift the cylinder to end stroke.

If any leakages should be still present, the cylinder is damaged and

then it must be replaced.

CYLINDER CHECKING METHODS

Loading...

Loading...