chapter 7000

page 16

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

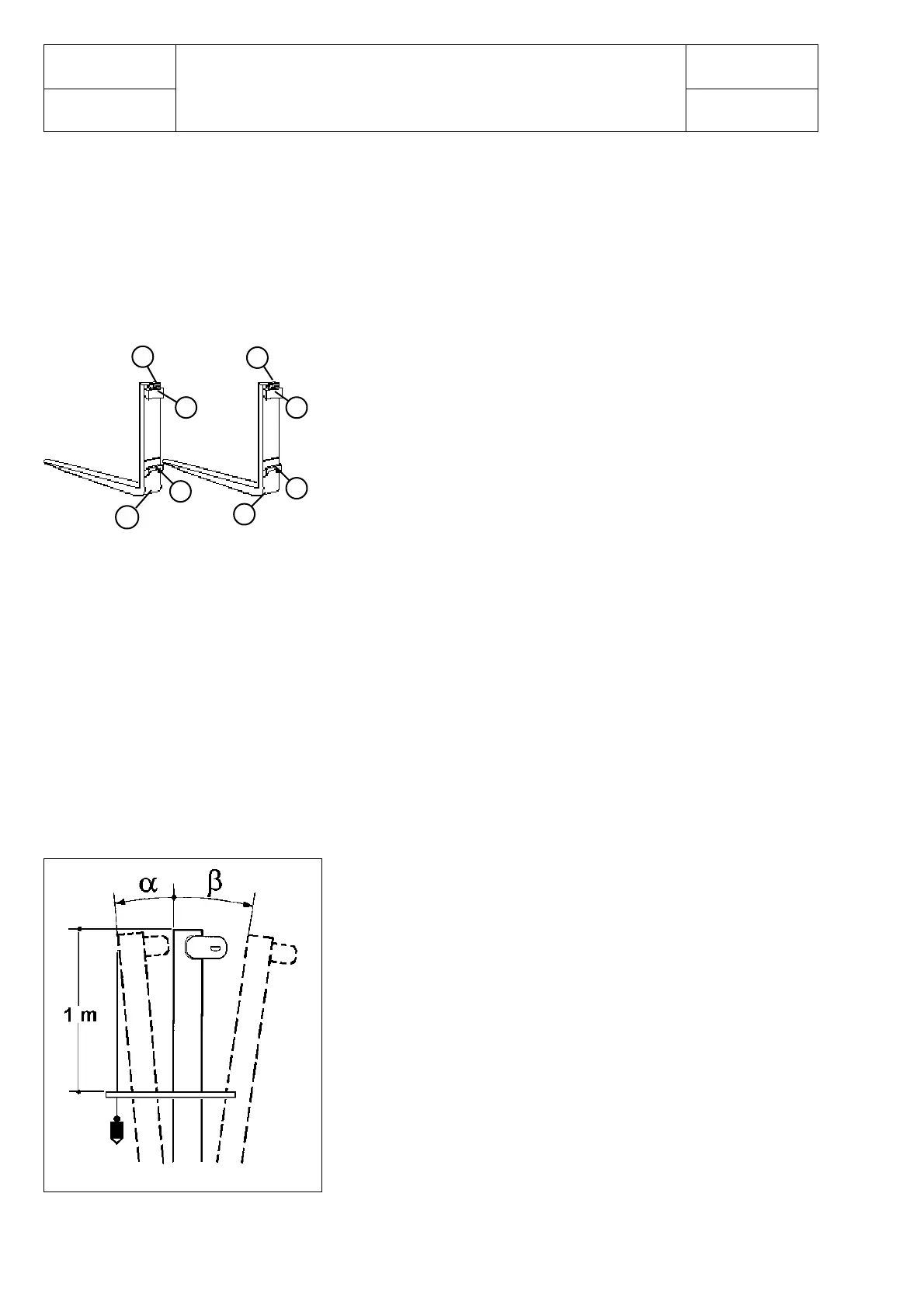

G

F

D

D

F

EE

G

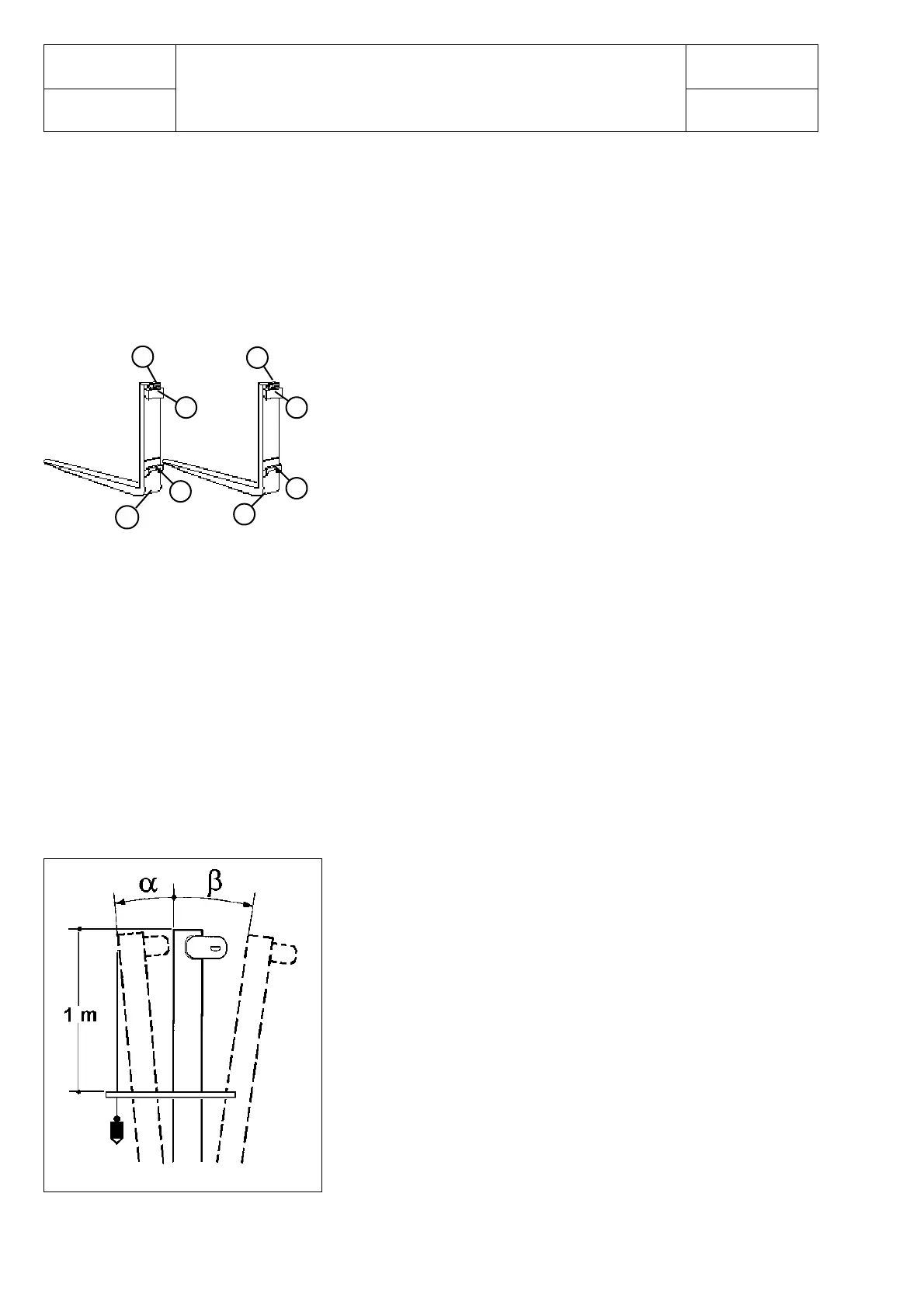

1° = 17,4 mm

<= FORWARD - BACKWARD=>

General criteria

Fork arms in use must be inspected at intervals of not

more than 1000 hours, and whenever a defect or permanent

deformation is detected. If the truck is subject to intensive use,

more frequent inspections may be required.

Inspection

Fork arm inspection must be carried out carefully by trained

personnel to detect any damage, failure, deformation, etc., which

may impair safe use.

Surface cracks

The fork arm must be thoroughly examined visually for cracks

giving special attention to the heel (D) and top (E) and bottom

(F) hooks. If necessary, the forks may be subjected to a non-

destructive crack detection process.

Difference in height of fork tips

Check the difference in height between the blade tips on each

pair of forks, this must not be more than 3% of blade length

with the forks fitted on the fork plate.

Positioning lock

Check that the fork positioning lock (G) is in good working

order.

Legibility of marking

If the fork arm marking is not clearly legible, it must be

renewed by the original fork supplier.

Fork wear control

The fork arm blade and shank must be thoroughly checked for

wear, paying special attention to the area around the heel (D).

When maximum wear is detected, with thickness reduced to

90% of the original, the fork arm must be replaced.

Fork mounting wear control

The horizontal supporting surface of the top hook (E) and the

contact surfaces of both hooks (E) and (F) must be checked

for wear and any damage.

Withdrawal of the forks from the service

Any fork with defects revealed during the above controls must

be withdrawn from service.

MAST GROUP TILTING SETTING

Every 500 hours

- control the tilting of the masts; the standard values (β) (α)

are the following:

α =2°30’ FORWARD = 43,7mm

β = 6° BACKWARD = 105,1 mm

The tilt angle can easily be checked using a plumb-line dropped from

the front outside edge of the top of the fixed masts and measuring the

distance between the line and the front edge at a metre from the top of

the masts.

N.B. 1 tilting degree corresponds to a 17.4 mm movement on 1 mt.

FORK INSPECTIONS

Loading...

Loading...