chapter 7000

page 12

1,2 - 2,0 t A.C.

SERVICE MANUAL

Electric

036-0410-07

E

E

C

D

P

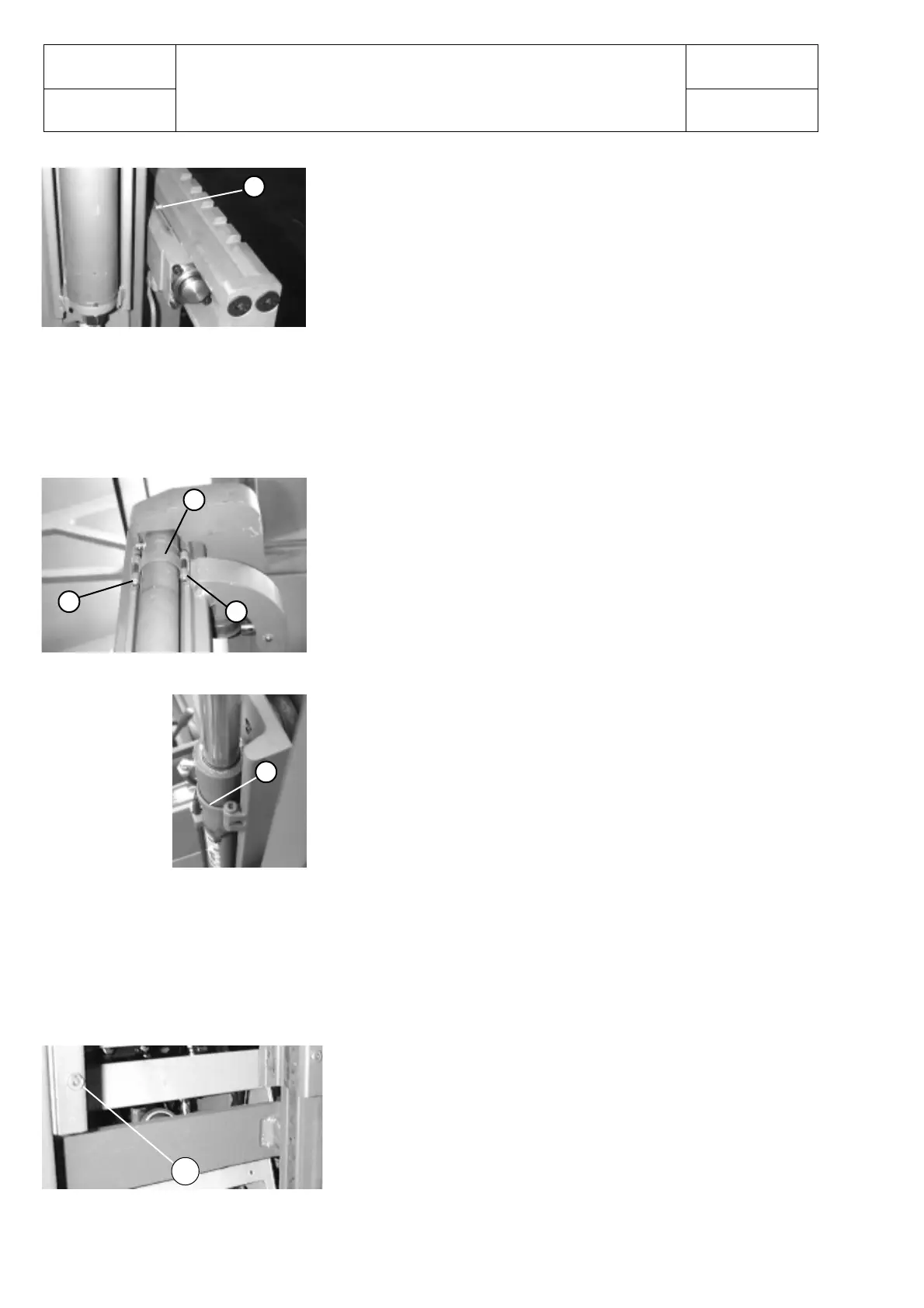

Sideshift unit

upper par 3 grease nipples (P)

lower part without grease nipples excessive wear.

Make sure that:

- the lifting chain stay bolts are free of defects and the adjusting

nuts are locked by the appropriate cotter pins (A);

- the fork carriage safety end stops (G) are present and tightly

fixed.

- the collars (C) are present and tightly fixed.

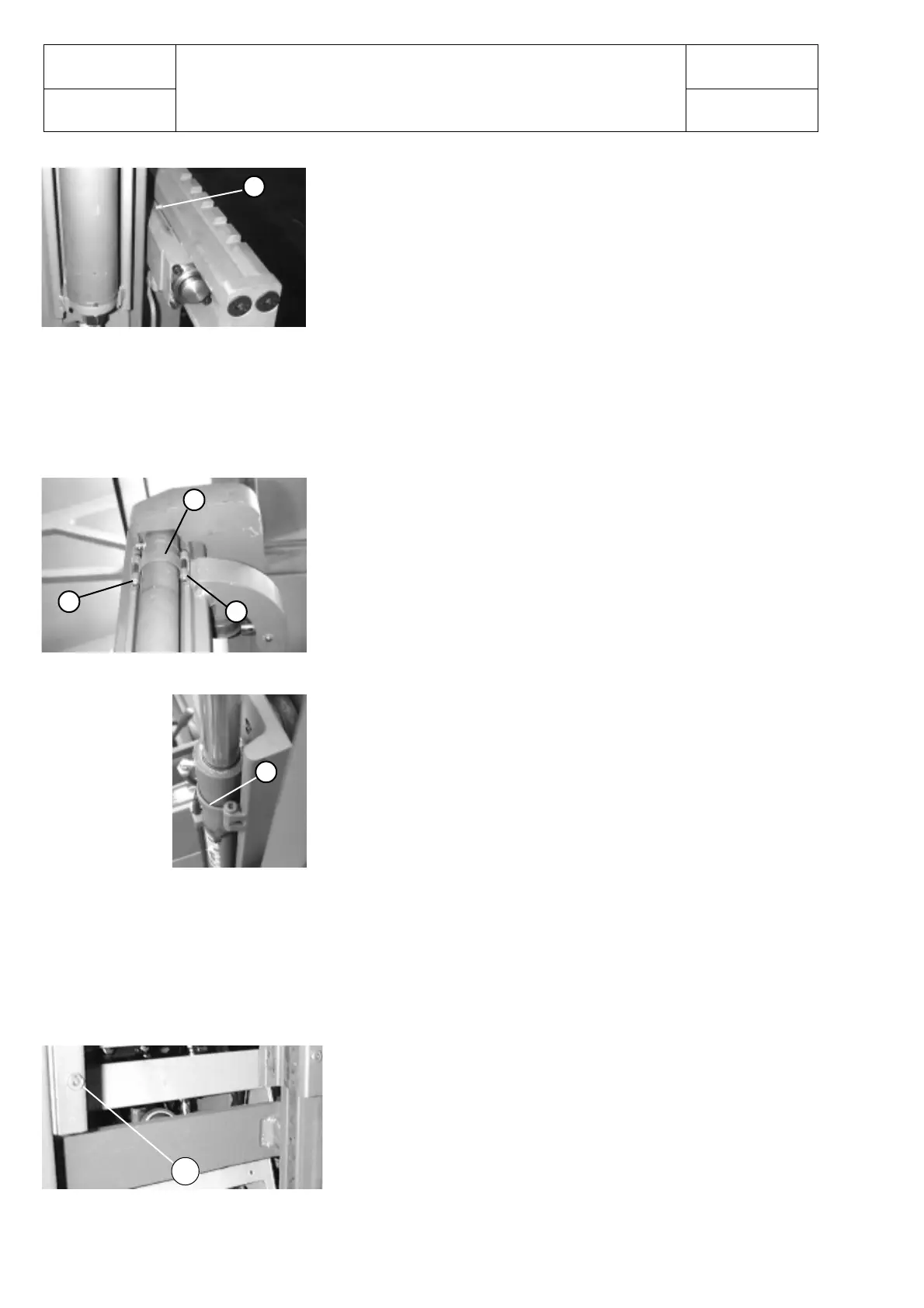

Every 500 hours

- check that there is a clearance (D); of 0.5 to 3 mm between

the collar and external lifting jack cylinder.

- check that the self-locking nuts (E) are tight.

Locking torques:

- collar self-locking nuts 0.8-1.2 daNm

The lifting unit is equipped with a mechanical safety end stop,

to avoid the accidental escape of the fork carriage from the botton

of the mast.

The end stops (G) consists of two Allen bolts. To remove the

fork carriage, first of all unscrew the end stops.

SAFETY FORK CARRIAGE END STOP

G

SECURITY INSTALLATIONS CONTROL

Loading...

Loading...