7 . ACCESSORIES AND OPTIONS

7.68

Challenger MT500B EU

7.13 - DUAL CONTROL APPLICATION

7.13.1 - General

The DUAL CONTROL is a system which automatically con-

trols implements in working position and at the end of the

field.

It also allows the rear linkage position to be carried over to

the front linkage position or to the depth wheel position of

a semi-mounted plough for example.

The information necessary for the correct operation of the

system is acquired by sensors, processed by the

"DATATRONIC 3" onboard computer and the electronic

linkage calculator which control the operation of an electro-

hydraulic spool (EHS) valve.

Using this application, the following can be controlled:

- a front and rear implement, with the FRONT DUAL

CONTROL (e.g.: a front roller and a combined rear

seeder (Fig. 154), a front and rear plough, etc.),

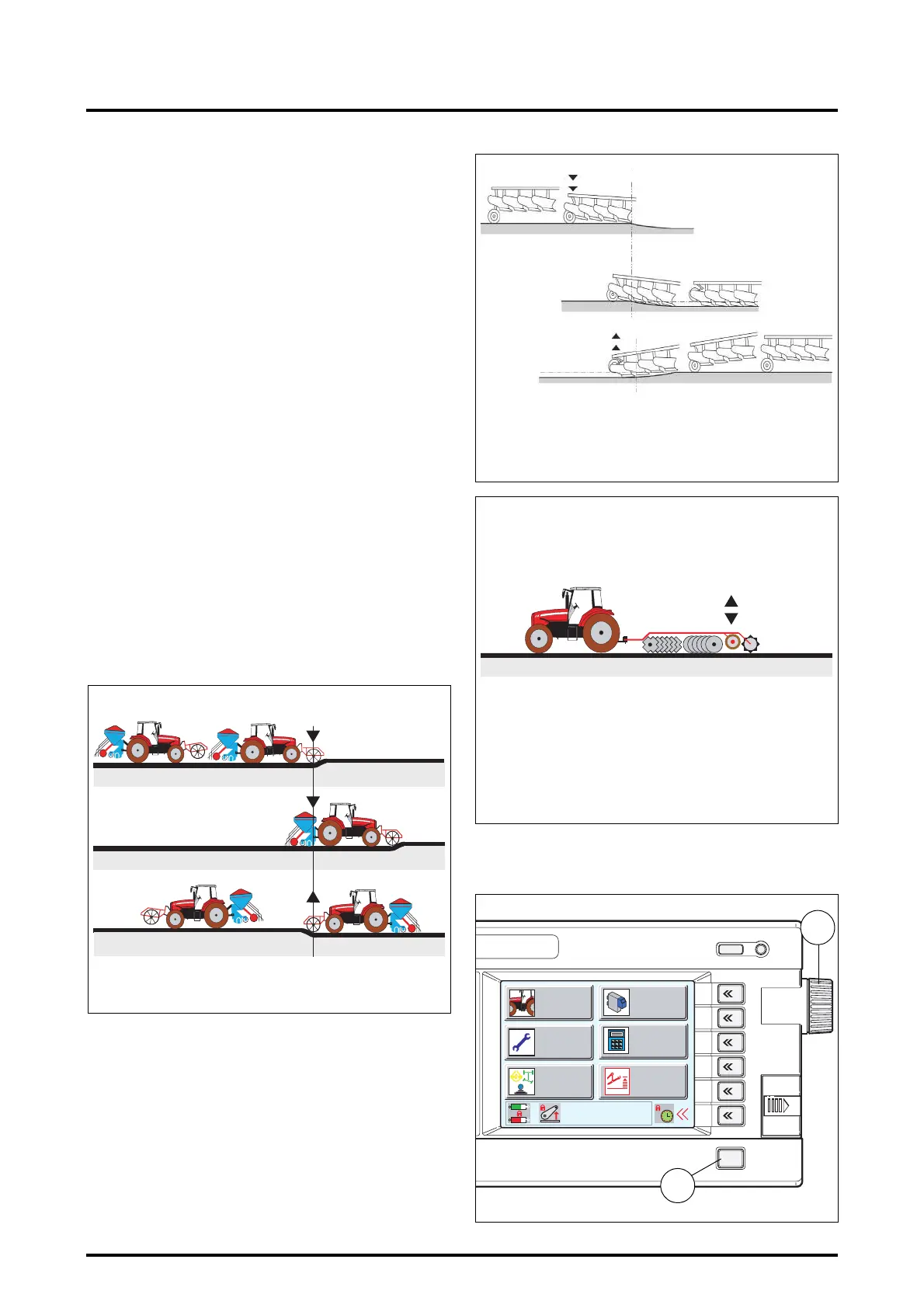

- a semi-mounted rear implement, with the REAR

DUAL CONTROL (e.g.: a semi-mounted plough (Fig.

155), a semi-mounted disc tiller, etc. These imple-

ments being hitched to the rear linkage),

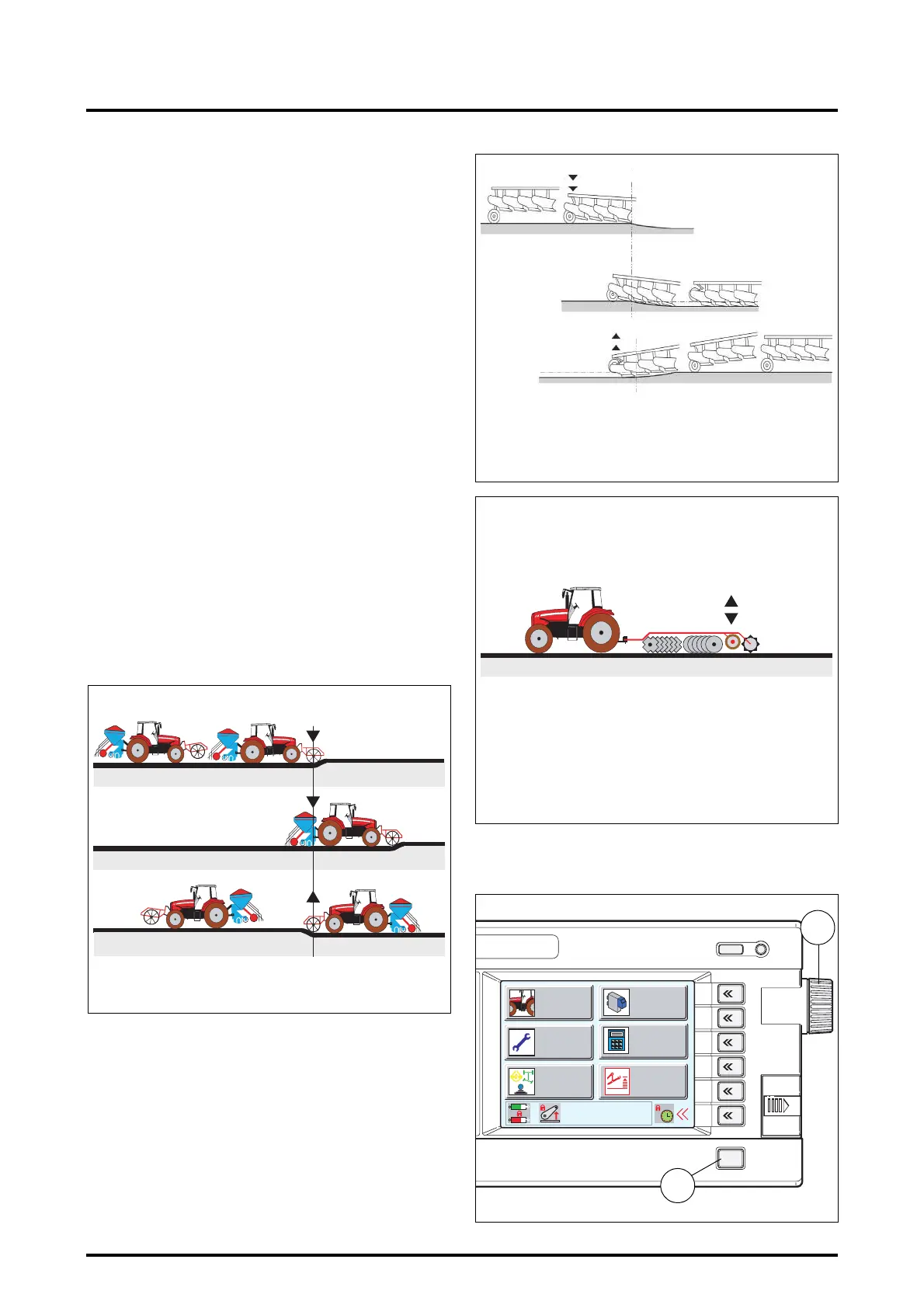

- a trailed rear implement with the TRAILED IMPLE-

MENT CONTROL (T. I. C.) (e.g.: a disc tiller (Fig. 156),

a trailed Chisel, etc.). These implements must be

hitched either to the swinging drawbar, or to the lift

arms. This system allows the implement height to be

set according to the wheel slip and the draft applied to

the lift arms (if the implement is hitched to the lift

arms).

To start the DUAL CONTROL application (Fig. 157):

• rotate the encoder (1) to the DUAL CTRL application.

Y

Z3A-944-08-04-B

Fig. 154

Y

Y

Z3A-808-08-04

Fig. 155

FURROW START

FURROW END

Z3A-945-08-04

Fig. 156

Z3A-938-08-04

1

2

3

4

5

6

ESC

Fig. 157

WORK

SETTINGS

HEADLAND DUAL CTRL

MEMORIES

EHS VALVES

1

2

Loading...

Loading...