5 Transmission

75

5.8 Assembly and Installation of Transmission

Follow the procedure for removal and disassembly of transmission in the reverse order for assembly and installation

and the below procedure for reference for adjustment and maintenance at assembly.

1 Assembly of Transmission

1. Clean each part sufficiently and assemble.

2. Make sure that snap rings for each part are securely attached.

3. Apply oil to the O-ring and needle bearing for assembly.

4. Apply lithium grease to the oil seal for assembly.

5. Assemble as shown in the drawing for the spur gears with specified mounting direction (edgy or chamfered

side).

6. Apply liquid packing (Threebond #1208D) to the matching face of mission case for assembly.

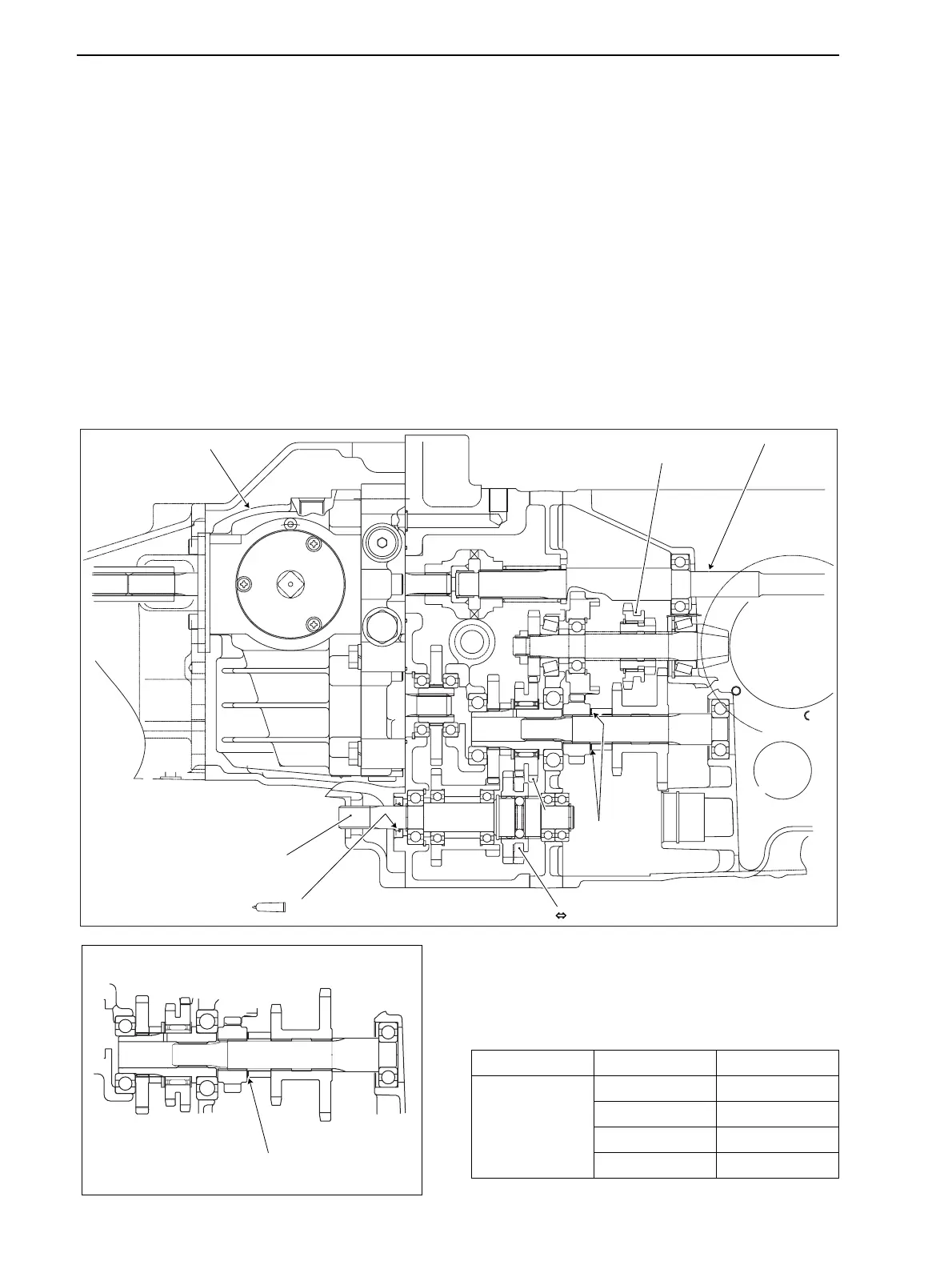

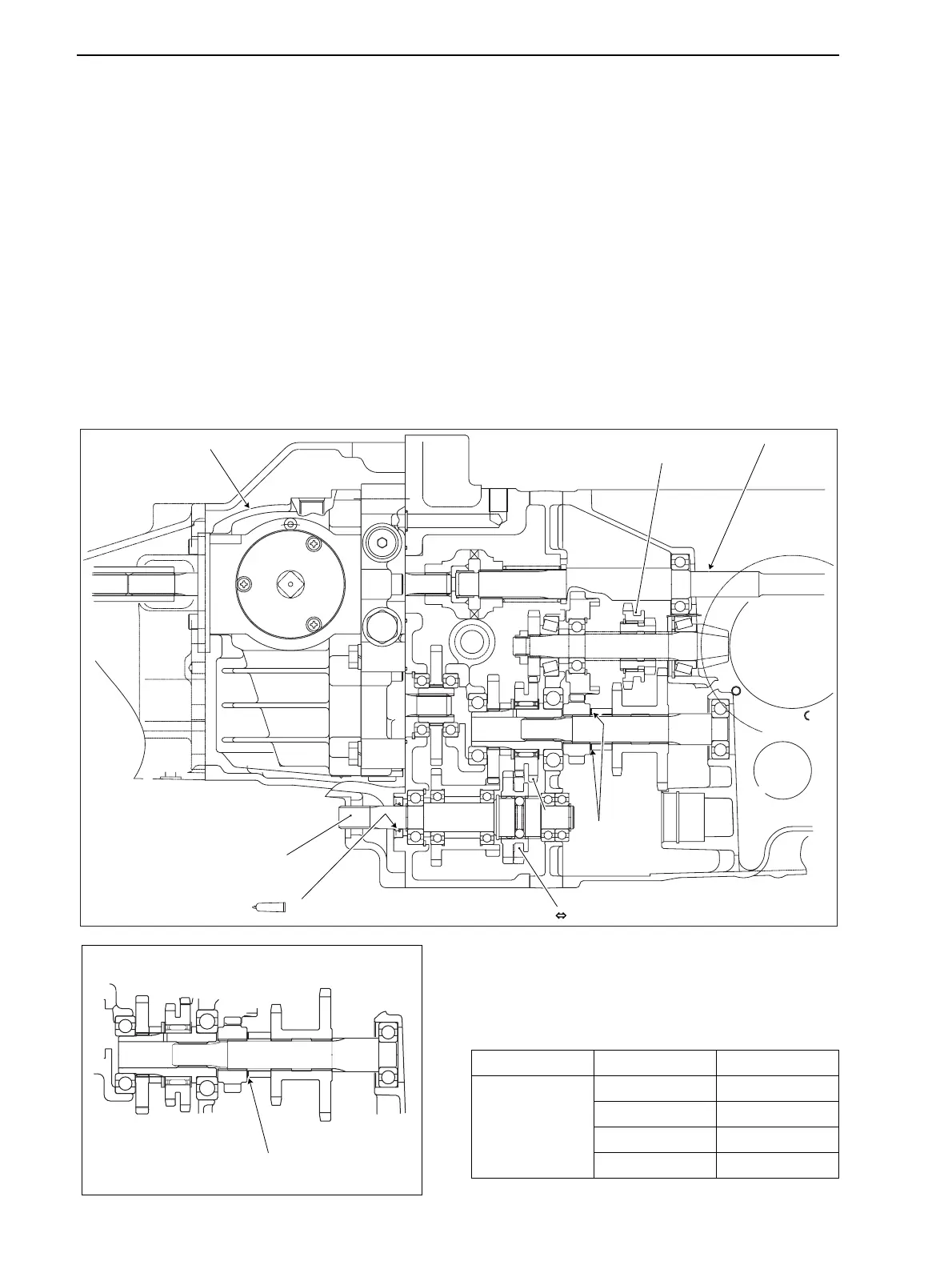

5.8.1 Assembly of Transmission Case Assembly (HST Specification)

1. Adjust the endplay shown in the drawing to be

within 0.05 to 0.20mm {0.002 to 0.008in} with

liner "A".

(Unit: mm {in})

Item Thickness Parts No.

Liner "A"

0.15 {0.006} 0731 0002 501

0.2 {0.008} 0731 0002 502

0.4 {0.016} 0731 0002 504

0.8 {0.031} 0731 0002 508

36T

34T

30T

30T

40T

18T

23T

22T

14T

35T

31T

32T

25T

25T

Shaft

Subgearing

low-speed-N-intermediate-N-high-speed

HSTunit

2WD4WD

4WDshaft

Grease

Liner"A"

GZ3W24-041

36T

30T

18T

25T

34T

35T

Liner"A"

GZ3W24-042

www.mymowerparts.com

K&T Saw Shop 606-678-9623 or 606-561-4983

Loading...

Loading...