For both small and large unit, the service switch is

optional.

The

switch

is

shown mounted on the motor side.

Alternatively, the switch can be located on the mains side,

or omitted.

For the large unit, the circuit breaker is optional. The large

unit can be configured with either service switch or circuit

breaker, not both. The illustration shown is not config-

urable in practice, but is displayed to show the respective

positions of components only.

2.4.3 Terminal Types

Motor, control, and mains terminals are spring loaded

(CAGE-CLAMP)

type.

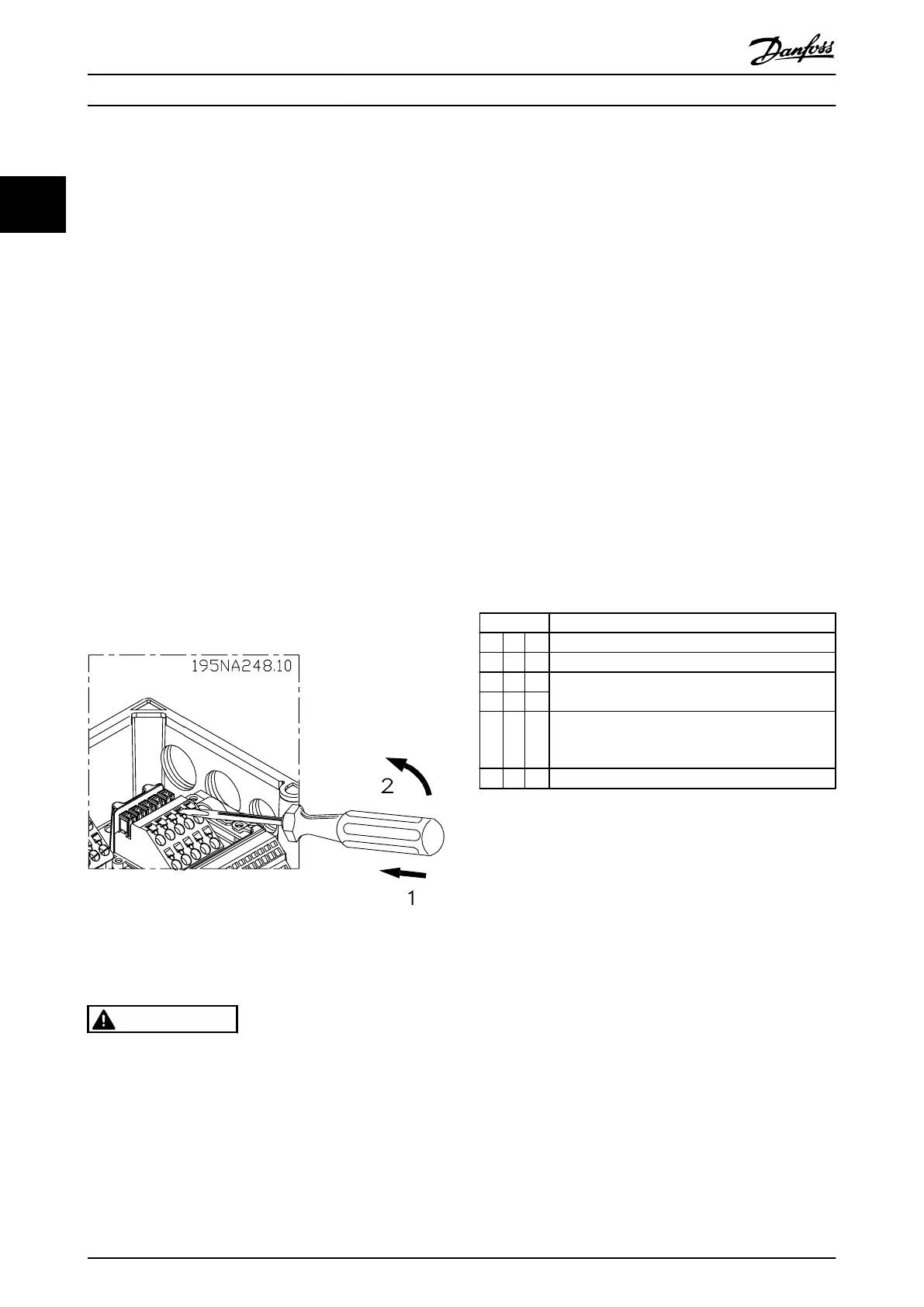

1. Open the contact

by inserting a small screwdriver

into the slot above the contact, as shown in

Illustration 2.14.

2. Insert the stripped wire into the contact.

3. Remove the screwdriver to fasten the wire into

the contact.

4. Ensure that the contact is firmly established and

not loose. Loose wiring can result in equipment

faults or injury.

Illustration 2.14 Opening the Terminals

2.4.4 Motor Connection

WARNING

INDUCED VOLTAGE

Run output motor cables

from multiple frequency

converters separately. Induced voltage from output motor

cables run together can charge equipment capacitors even

with the equipment turned off and locked out. Failure to

run output motor cables separately could result in death

or serious injury.

CAUTION

WIRING ISOLATION

Run input power,

motor wiring, and control wiring in three

separate metallic conduits. Alternatively, use separated

shielded motor and control cables for high frequency noise

isolation. Failure to isolate power, motor and control wiring

can result in sub-optimal performance of the frequency

converter and associated equipment.

MOTOR PROTECTION

Protection against motor overload is not included in the

factory setting. If this function is desired, set 1-90 Motor

Thermal Protection to trip or warning. Refer to the FCD 302

Programming Guide, MG04GXYY for further information.

•

Connect the motor to terminals 96, 97, 98.

•

Connect earth to PE-terminal.

•

Make sure that the screen of the motor cable is

properly earthed at both ends (motor and

frequency converter).

•

For correct dimensioning of cable cross-section,

see 8.1.1 Electrical Data and Wire Sizes.

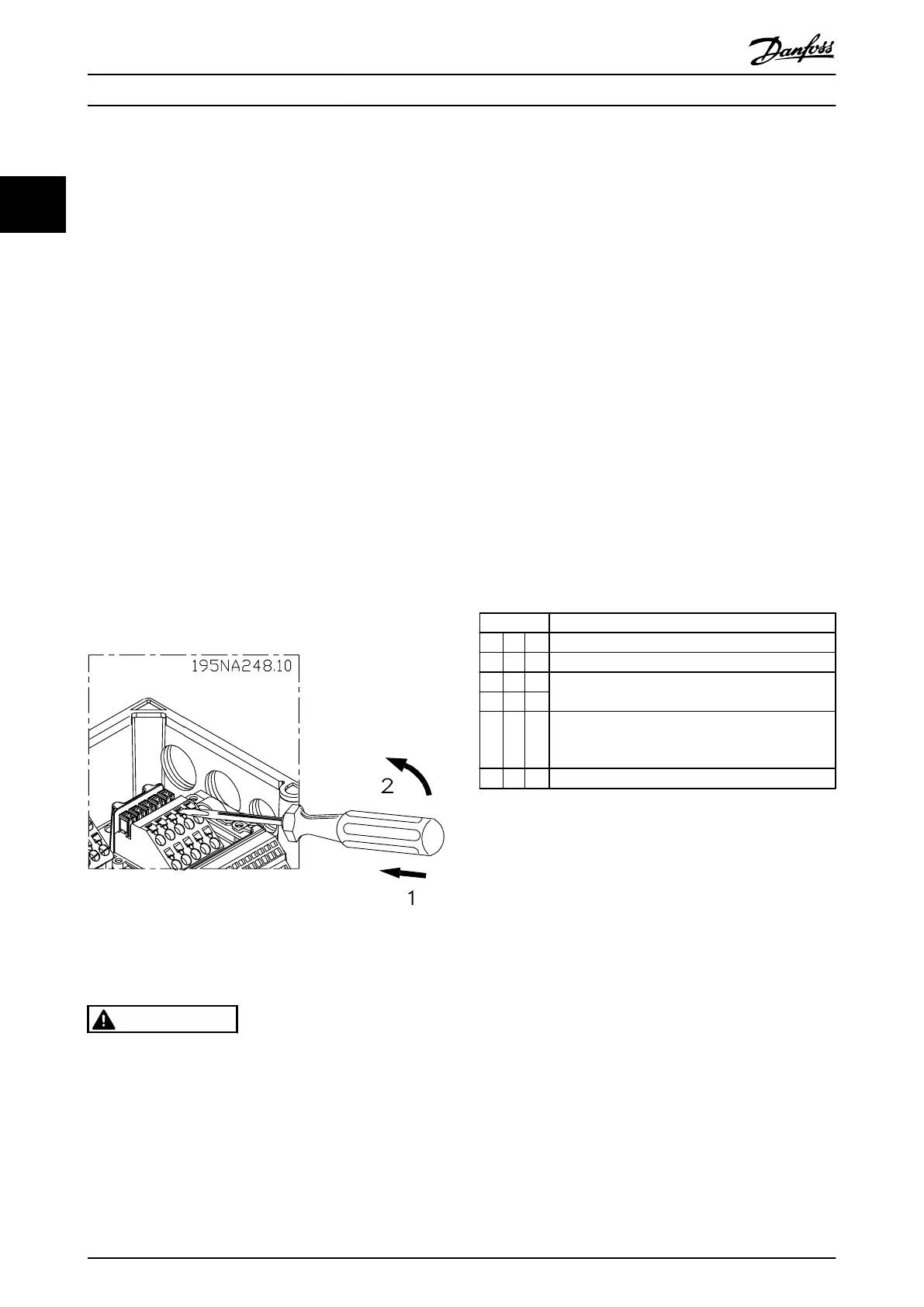

No.

96 97 98 Motor voltage 0-100% of mains voltage

U V W 3 wires out of motor

U1 V1 W1

6 wires out of motor

W2 U2 V2

U1 V1 W1 6 wires out of motor, Star connected

Connect

U2, V2, W2

separately (optional terminal

block)

PE Earth connection

NOTE

Do not install power

factor correction capacitors between

the frequency converter and the motor.

Do not wire a starting or pole-changing device between

the frequency converter and the motor.

Parallel connection of motors

The frequency converter can

control several parallel-

connected motors. The total current consumption of the

motors must not exceed the rated output current I

M,N

for

the frequency converter.

Installation

VLT

®

Decentral Drive FCD 302 Operating Instructions

18 MG04F302 - VLT

®

is a registered Danfoss trademark

22

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...