1.4 Additional Resources

Other resources are available to understand advanced

frequency controller functions and programming.

•

The FCD 302 Programming Guide, MG04GXYY,

provides greater detail in how to work with

parameters and many application examples.

•

The FCD 302 Design Guide, MG04HXYY, is intended

to provide detailed capabilities and functionality

to design motor control systems.

•

MCB 102 manual

•

MCB 103 manual

•

Safe PLC Interface Option MCB 108 instruction,

MI33JXYY

.

•

Fieldbus manuals: Profibus manual

MG34NXYY,

Ethernet manual MG90JXYY, and ProfiNet manual

MG90UXYY.

•

Brake Resistor Design Guide MG90OXYY

•

Training courses both on-line and in person.

•

Hotline, telephone and on-line help.

•

Installation, set up, and commissioning is also

available by Danfoss trained and approved

installers.

•

Danfoss sales representatives are also trained to

provide customer service and instruction for

applications.

Contact your Danfoss supplier or go to Danfoss website

for downloads or additional information. In technical

literature reference numbers, X refers to version number

and YY refers to language code.

1.5 Product Overview

A frequency converter is an electronic motor controller

that converts AC mains input into a variable AC waveform

output. The frequency and voltage of the output are

regulated to control the motor speed or torque.

In addition, the frequency converter monitors the system

and motor status, issues warnings or alarms for fault

conditions, starts and stops the motor, optimizes energy

efficiency, provides line harmonics protection, and offers

many more control, monitoring, and efficiency functions.

Operation and monitoring functions are available as status

indications to an outside control system or serial communi-

cation network.

The FCD 302 is designed for decentral mounting, for

example, in the food and beverage industry, or for other

material handling applications. With the FCD 302 it is

possible to reduce costs by placing the power electronics

decentrally. Central panels are then rendered obsolete,

saving cost, space and effort for installation and wiring.

The basic design is service-friendly, with a pluggable

electronic part and a flexible and “spacious” wiring box. It

is easy to change electronics without the need for re-

wiring.

1.6 Internal Frequency Converter Controller

Functions

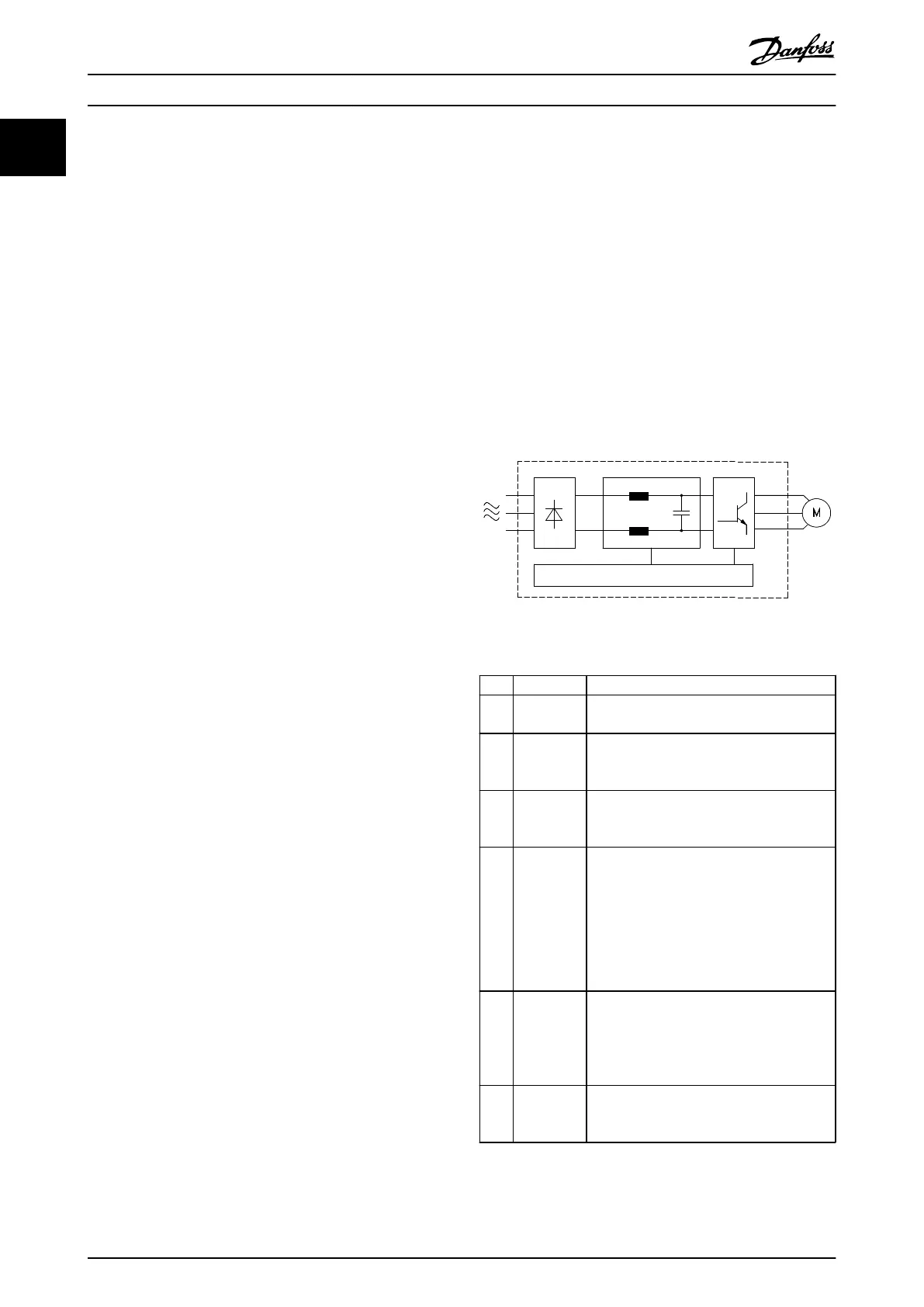

Below is a block diagram of the internal components of

the frequency converter. See Table 1.1 for their functions.

Illustration 1.1 Frequency Converter Block Diagram

Area Title Functions

1 Mains input Three-phase AC mains power supply to the

frequency

converter.

2 Rectifier The rectifier

bridge converts the AC input to

DC current for use

within the frequency

converter.

3 DC bus The intermediate DC-bus circuit of the

frequency converter handles the

DC current

for internal routing.

4 DC line

reactors

•

Filter the intermediate DC

circuit voltage

•

Prove line transient protection

•

Reduce RMS current

•

Raise the power factor reflected back to

the line

•

Reduce harmonics on the AC input

5 Capacitor

bank

•

Stores the DC power

•

Provides

a regulated DC current supply

•

Provides ride-through protection for

short power losses

6 Inverter The inverter converts the DC into a

controlled PWM AC waveform

for a

controlled variable output to the motor.

Introduction

VLT

®

Decentral Drive FCD 302 Operating Instructions

6 MG04F302 - VLT

®

is a registered Danfoss trademark

11

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...