Inspect for Description

☑

Input and

output power

wiring

•

Check for loose

connections

•

Check for proper fusing or circuit

breakers

Switches Ensure that all switch and disconnect

settings are in the

proper position.

Grounding The equipment requires a dedicated

ground wire from its

chassis to the

plant ground. Check for good ground

connections that are tight and free of

oxidation.

Installation

box and

electronics

part

Ensure the installation

box and the

electronics part is properly closed.

Check that all four fastening screws are

tightened with the right torque.

Cable glands

and blind

plugs

Ensure the cable

glands and blind

plugs are properly tightened, to

guarantee the right enclosure

protection degree is achieved. Liquids

and/or excessive dust ingress in the

drive can cause sub-optimal

performance or damage.

Vibration Ensure the equipment is not exposed

to a high level

of vibration. Mount the

panel solidly or use shock mounts as

necessary.

Table 3.1 Start Up Check List

3.2 Applying Power to the Frequency

Converter

WARNING

HIGH VOLTAGE

Frequency converters contain high

voltage when

connected to AC mains input power. Only qualified

personnel must perform installation, start-up and

maintenance. Failure to perform installation, start-up and

maintenance by qualified personnel could result in death

or serious injury.

1. Perform pre-start up procedure described in

3.1 Pre-start.

2. Confirm input

line voltage is balanced within 3%.

If not, correct input voltage imbalance before

proceeding. Repeat procedure after voltage

correction.

3. Ensure optional equipment wiring, if present,

matches installation application.

4. Ensure that all operator devices are in OFF

position.

WARNING

UNINTENDED START

When frequency converter is

connected to AC mains input

power, the motor may start at any time. The frequency

converter, motor, and any driven equipment must be in

operational readiness. Failure to be in operational

readiness when the frequency converter is connected to

AC mains could result in death, serious injury, equipment,

or property damage.

5. Apply power to the unit. DO NOT start the

frequency converter at this time. For units with a

disconnect switch on the mains side, turn to the

ON position to apply power to the frequency

converter.

3.3 Quick Setup

Frequency converters require basic operational

programming before running for

best performance. Basic

operational programming requires entering motor-

nameplate data for the motor being operated and the

minimum and maximum motor speeds. Enter this data in

accordance with the following procedure. See 4 User

Interface, for detailed instructions on entering data through

the LCP. Enter this data with power ON, but before

operating the frequency converter.

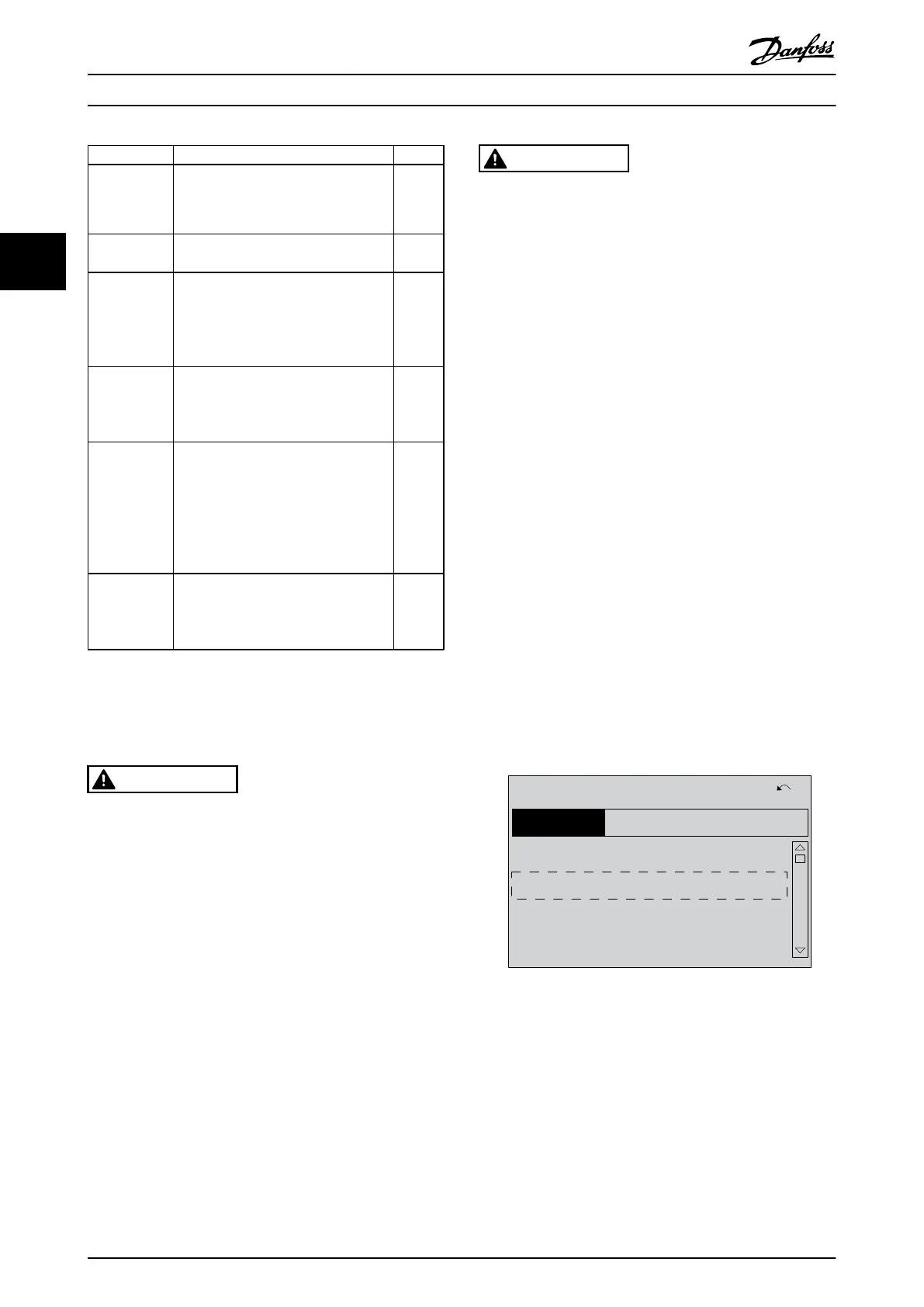

1. Press [Quick Menu] on the LCP.

2. Use the navigation keys to scroll to parameter

group Q2 Quick Setup and press [OK].

130BC394.10

Q1 My Personal Menu

Q2 Quick Setup

Q3 Function Setups

Q5 Changes Made

13.7% 0.75A 1 (1)

Quick Menus

3. Select language and press [OK]. Then enter the

motor data in 1-20 Motor

Power [kW]/1-21 Motor

Power [HP] through 1-25 Motor Nominal Speed.

The information can be found on the motor

nameplate. The entire quick menu is shown in

International/North American Default Parameter

Settings

1-20 Motor Power [kW]

1-21 Motor Power [HP]

Start Up and Functional Tes...

VLT

®

Decentral Drive FCD 302 Operating Instructions

30 MG04F302 - VLT

®

is a registered Danfoss trademark

33

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...