1. Use a wire stripper to remove the insulation for

proper

grounding.

2.

Secure

the

grounding clamp to the stripped

portion of the wire with the screws provided.

3. Secure the grounding wire to the grounding

clamp provided.

Leakage current (3.5 mA)

NOTE

Follow national and local codes regarding protective

earthing of equipment with a leakage current > 3.5 mA.

The frequency converter technology implies high

frequency switching at high

power. This generates a

leakage current in the earth connection. RFI filtering and

screened motor cables contribute to this phenomenon.

According to EN/IEC61800-5-1 (Power Drive System

Product Standard) which implies special means if the

leakage current exceeds 3.5 mA, earth grounding must be

reinforced in one of the following ways:

•

Earth ground wire, 10 mm

2

(optional accessory

required for mounting, part no. 130B5974).

•

Two separate earth ground wires both complying

with the dimensioning rules.

RCD use

A fault current in the frequency converter or at the output

power terminals can contain a DC component, and

charging of the filter capacitors can cause a transient earth

current. Where Residual Current Devices (RCDs), also

known as Earth Leakage Circuit Breakers (ELCBs), are used,

the following must be taken into account:

•

Use RCDs of type B only

•

Use RCDs with an inrush delay

•

Use RCDs of 300 mA, if possible

2.4.12 Earthing of Screened Control Cables

Correct screening

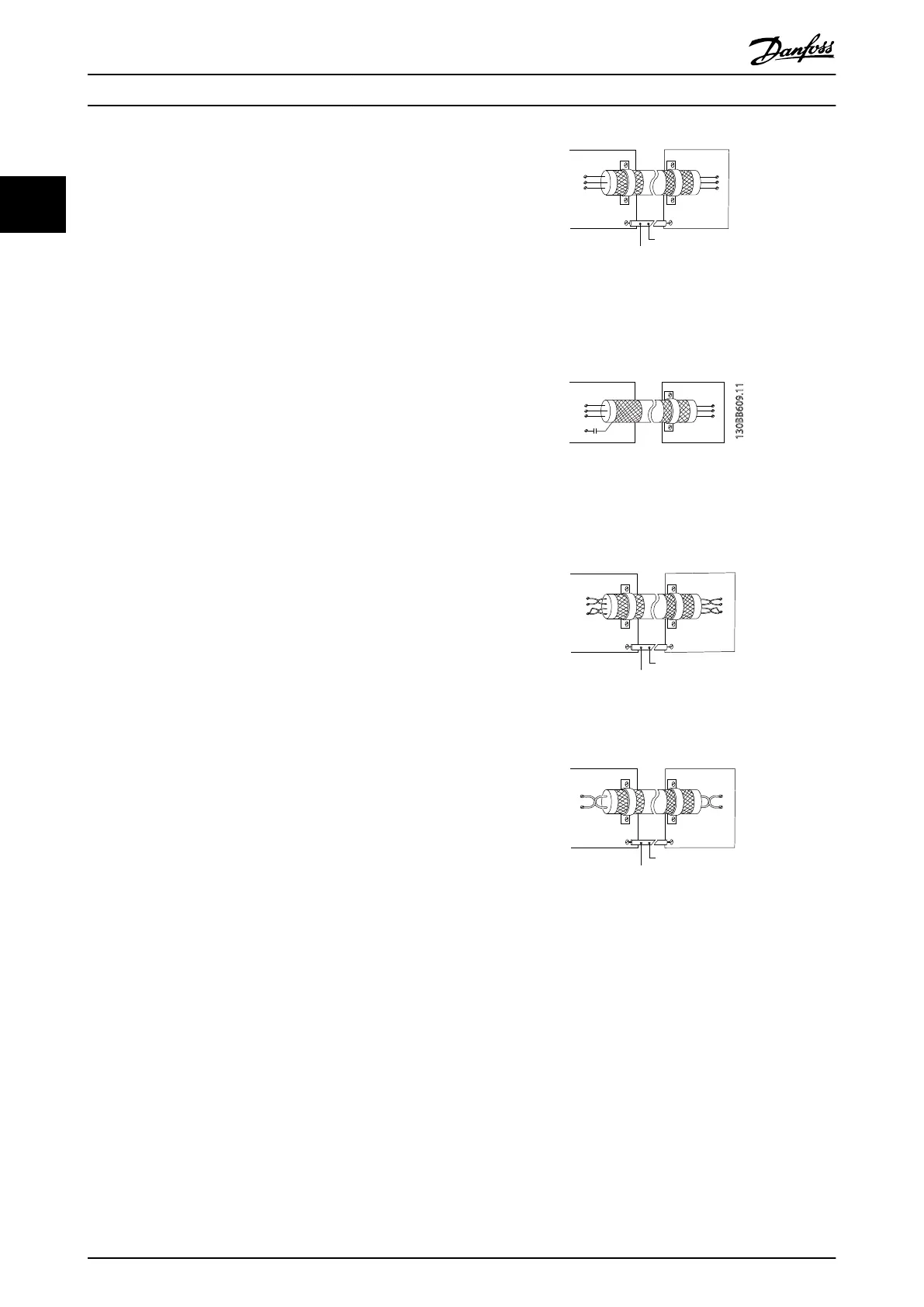

The preferred method in most cases is to secure control

and serial communication cables with screening clamps

provided at both ends to ensure best possible high

frequency cable contact.

If the earth potential between the frequency converter and

the PLC is different, electric noise may occur that will

disturb the entire system. Solve this problem by fitting an

equalizing cable next to the control cable. Minimum cable

cross section: 16 mm

2

.

Min. 16 mm²

PE

FC

PE

PLC

130BB922.10

PE PE

- Equalizing cable

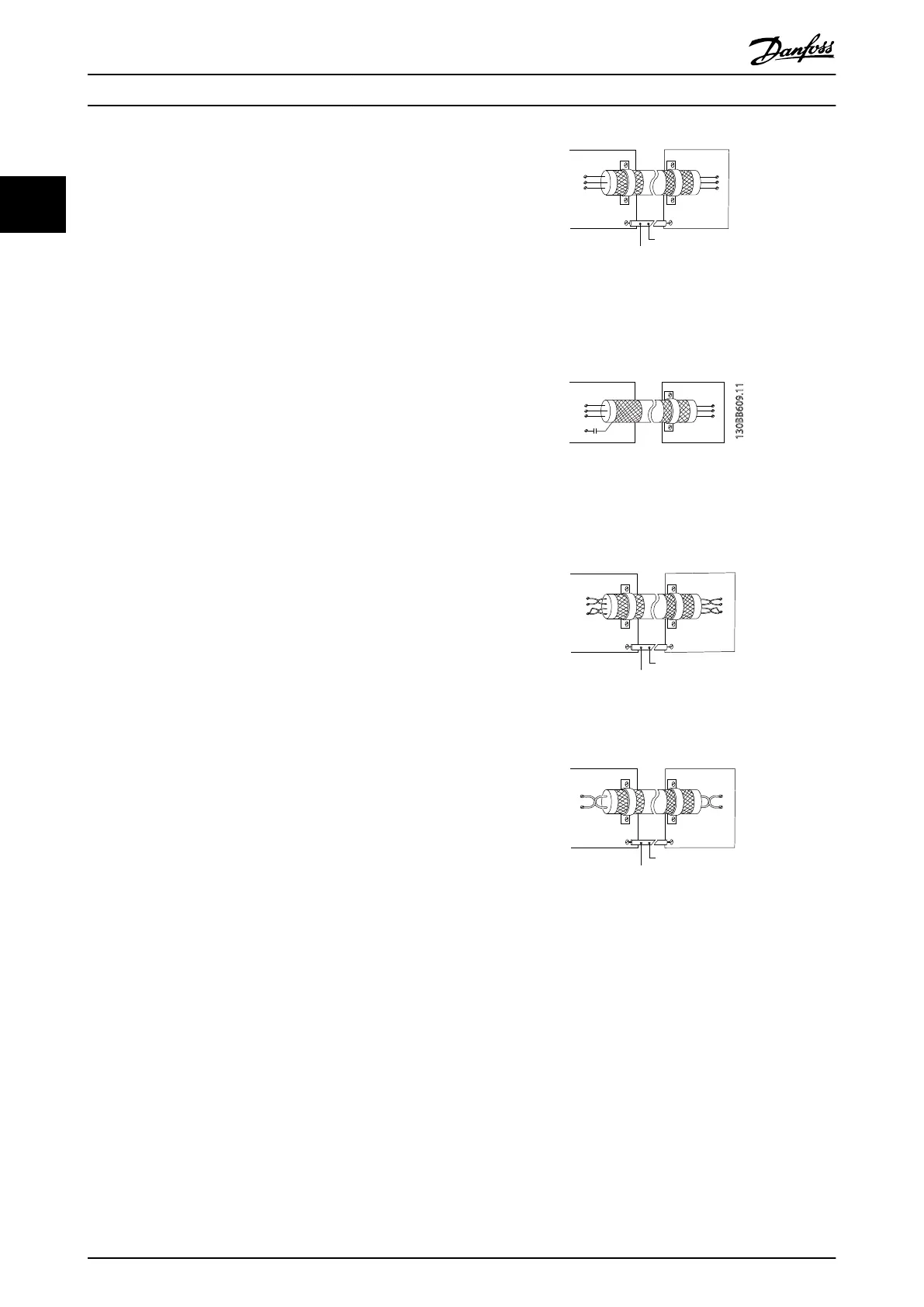

50/60 Hz ground loops

With very long control

cables, ground loops may occur. To

eliminate ground loops, connect one end of the screen-to-

ground with a 100nF capacitor (keeping leads short).

100nF

FC

PE

PE

PLC

130BB609.11

Avoid EMC noise on serial communication

This terminal is connected

to earth via an internal RC link.

Use twisted-pair cables to reduce interference between

conductors. The recommended method is shown below:

Min. 16 mm²

PE

FC

PE

FC

130BB923.10

PE PE

- Equalizing cable

69

68

61

69

68

61

Alternatively, the connection to terminal 61 can be

omitted:

Min. 16 mm²

PE

FC

PE

FC

130BB924.10

PE PE

- Equalizing cable

69

69

68

68

2.4.13 DIP Switches

•

Analog input terminals 53

and 54 can select for

either voltage (0-10 V) or current (0-20 mA) input

signals

•

Set switches S201 (terminal 53) and S202

(terminal 54) to select the signal type. ON is for

current, OFF for voltage

•

Terminal 53 default is for a speed reference in

open loop

•

Terminal 54 default is for a feedback signal in

closed loop

Installation

VLT

®

Decentral Drive FCD 302 Operating Instructions

24 MG04F302 - VLT

®

is a registered Danfoss trademark

22

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...