In hoisting/lowering applications, control of electro-

mechanical

brake

is

required:

•

The

brake is controlled using the special

mechanical brake control/supply terminals 122

and 123.

•

Select [32] Mechanical brake control in parameter

group 5-4*, [1] Array, Relay 2 for applications with

an electro-mechanical brake.

•

The brake is released when the motor current

exceeds the preset value in 2-20 Release Brake

Current.

•

The brake is engaged when the output frequency

is less than the frequency set in 2-21 Activate

Brake Speed [RPM] or 2-22 Activate Brake Speed

[Hz]. The brake engages only when the frequency

converter performs a stop command.

When the frequency converter enters alarm mode or is

exposed to an over-voltage situation, the mechanical brake

immediately cuts in. For more detailed information, refer to

the FCD 302 Programming Guide, MG04GXYY.

NOTE

When

the Mechanical Brake

Control/Supply terminals 122

and 123 are set through parameter group 5-4*, [1] Array,

Relay 2, only one relay output (Relay 1) is available for free

programming.

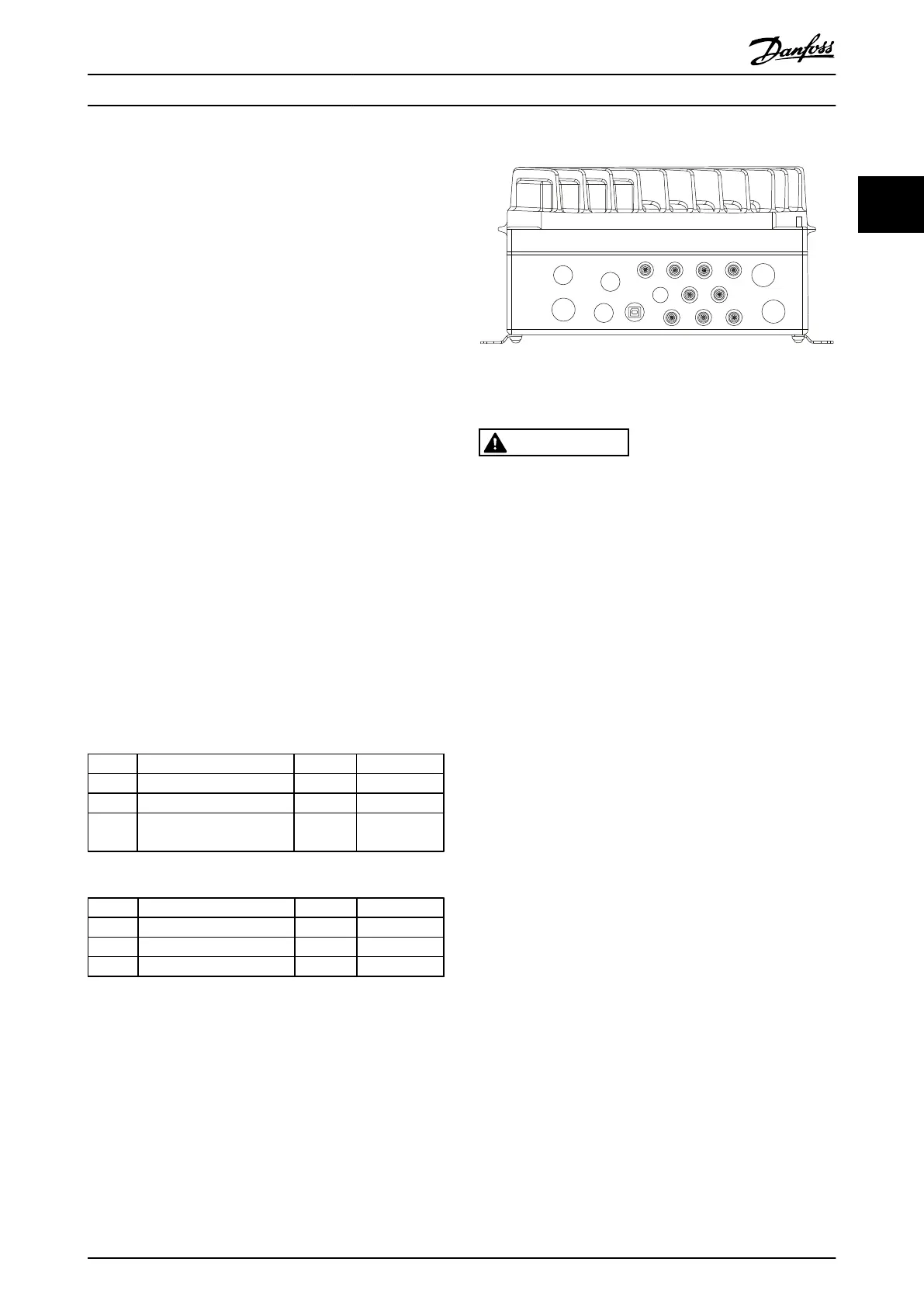

2.4.10 Connection of Sensors/Actuators on

M12

Sockets

Pin Wire colour Terminal Function

1 Brown 12

+24 V

3 Blue 20 0 V

4 Black 18, 19, 32,

33

Digital input

Table 2.1 4xM12 Connection Input

Pin Wire colour Terminal Function

1 Brown Reserved* Reserved

3 Blue 20 0 V

4 Black 02, 05 N.O. (24 V)

Table 2.2 2xM12 Connection Output

* When reserved wires

for option are used. If not utilised, they can be

cut off.

130BC389.10

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

LCP

RL2

RL1

33

USB

3219

FB2 FB1

18

1

2

3

4

1

2

3

4

2.4.11 Earth (Grounding) Requirements

WARNING

GROUNDING HAZARD

For operator safety, it

is important to ground frequency

converter properly in accordance with national and local

electrical codes as well as instructions contained within

this manual. Ground currents are higher than 3.5 mA.

Failure to ground frequency converter properly could

result in death or serious injury.

NOTE

It is the responsibility

of the user or certified electrical

installer to ensure correct grounding (earthing) of the

equipment in accordance with national and local electrical

codes and standards.

•

Proper

protective grounding for

equipment with

ground currents higher than 3.5 mA must be

established, see Leakage Current (3.5 mA)

following.

•

A dedicated ground wire is required for input

power and motor.

•

Use the clamps provided with on the equipment

for proper ground connections.

•

Use of high-strand wire to reduce electrical noise

is recommended.

Installation

VLT

®

Decentral Drive FCD 302 Operating Instructions

MG04F302 - VLT

®

is a registered Danfoss trademark

21

2 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...