Installing and Commissioning the Dräger Polytron Pulsar 2

24

30 to 120m and 100 to 200m Transmitters

Connect the Handheld and check that the signals from the Receiver are being displayed. If they were absent it would indicate that the dig-

ital link from the Receiver was not connected, usually due to a wiring fault. Also look into the Transmitter lens to check it is flashing at the

correct, irregular rate of four per second. A regular twice per second would indicate inadequate voltage at the supply or excessive voltage

drop in the supply cables.

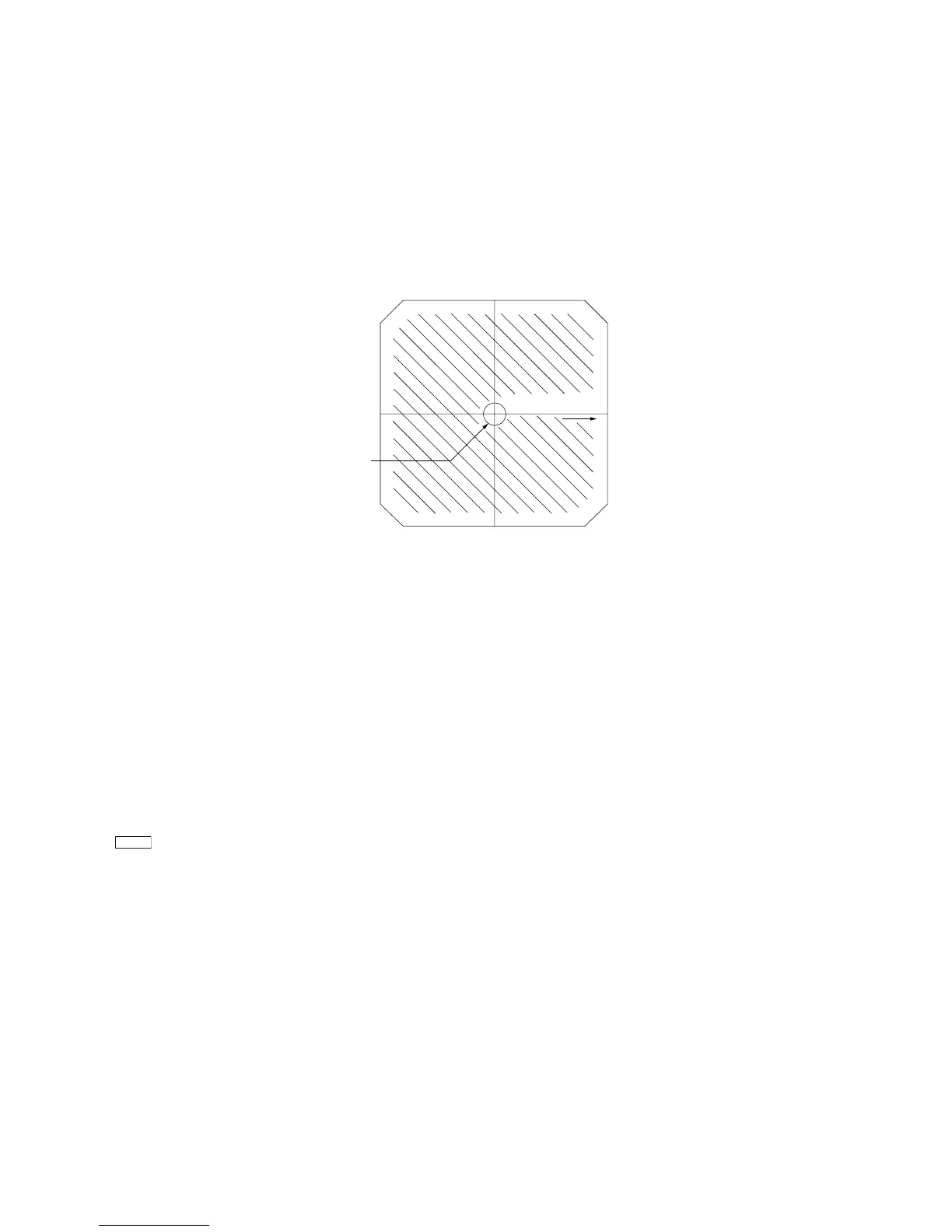

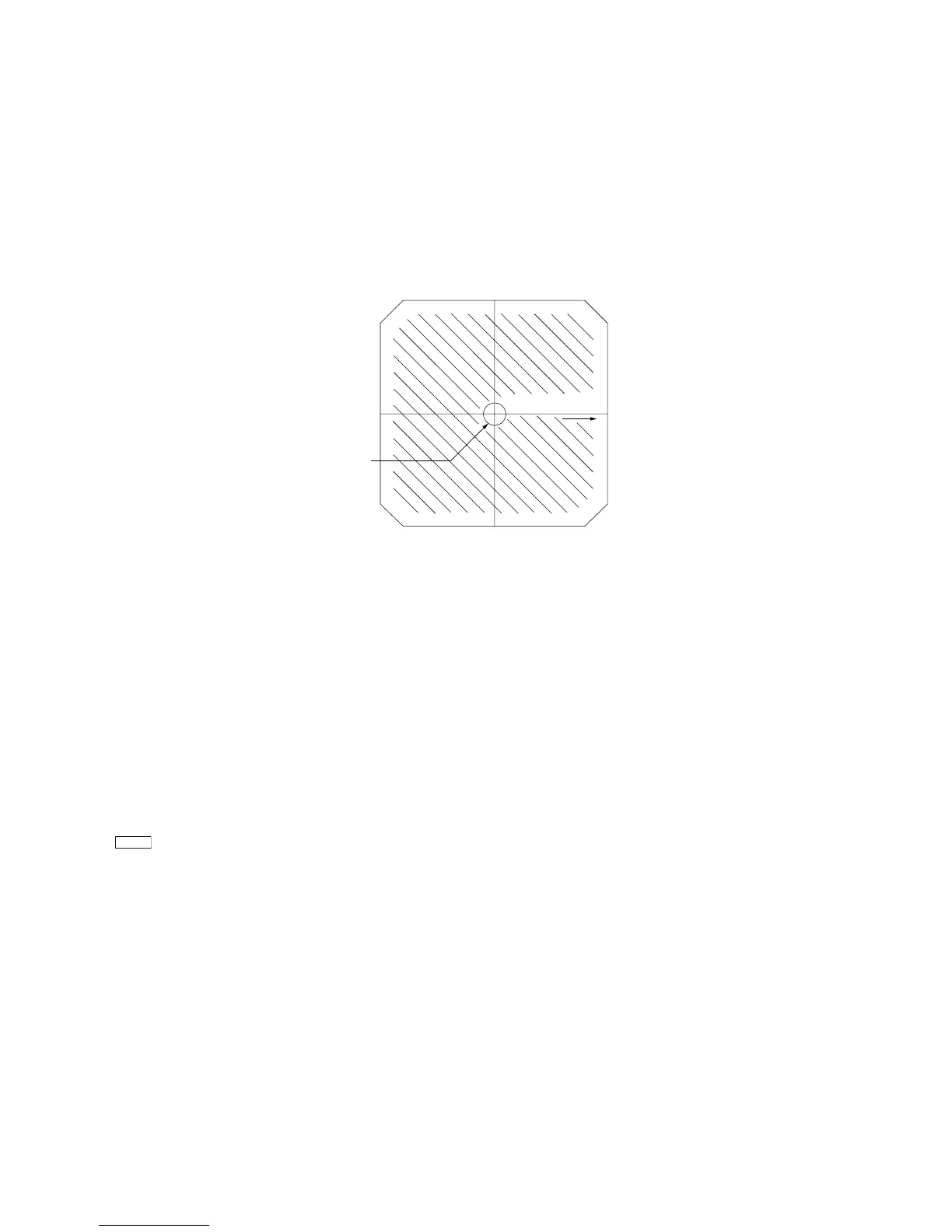

At the left of the Alignment screen the Transmitter 'target' indicates the degree of misalignment but not (unlike the Receiver) its direction:

First move the Transmitter around to be sure you have found the strong central peak in signal. Make slow adjustments, first vertically then

horizontally, to maximise the signal strength. The final horizontal adjustment moves the circle from right to left, until the display matches

the diagram. Tighten the eight screws progressively in rotation to avoid losing the alignment. The Transmitter and connector covers can

now be replaced.

Step 3. Final Receiver alignment

As you return to the Receiver use the portable detector to check that the beam path is free of gas, in preparation for the zeroing proce-

dure that follows. At the Receiver, make any final adjustment needed to centre the display. This is more likely to be necessary if the initial

alignment was poor, or if the operating distance is short, causing movements of the Transmitter to have a proportionately larger angular

effect at the Receiver. Replace the Receiver cover, ensuring all the screws are tight. Leave the Handheld connected for Step 4.

Step 4. The Zeroing Procedure

The Zeroing Procedure must be carried out whenever the Dräger Polytron Pulsar 2 is cleaned or realigned. It checks the installation and

stores measurements for the normal situation that the path is free of gas and has good visibility. These form the standards of comparison

to detect dirt on the lenses and gas in the path, so it is essential that the beam is unobstructed by people or objects and there is no fog or

gas in the air. For preference choose a time when the weather is dry, the temperature moderate, and the Dräger Polytron Pulsar 2 has

been powered for at least 30 minutes.

Select from the 'Rx Align + Zero' menu. There is a countdown from 32 to show the progress of the zeroing and a display of relevant

measurements such as the Receiver's (internal) temperature and supply voltage. The countdown proceeds slowly at first, then more rap-

idly as the Transmitter switches to Strong Mode. It should reach zero in about 40 seconds and then be replaced by a zero gas reading,

showing that the procedure is complete. If any of the checks on the installation fail then the countdown will halt or re-start. They are delib-

erately made more stringent, for instance in the accuracy of alignment required, than the laxer standards that would allow a working

Dräger Polytron Pulsar 2 to remain so. You are prompted to press a key to see an explanation of the problem.

The countdown visible at the Handheld is accompanied by a downward ramping of the analogue current loop signal from 20mA. This

allows personnel in the Non-hazardous Area to follow the progress of the zeroing and to check that the analogue circuit is not prevented

from reaching full scale.

Step 5. Verification with Test Sheets

The purpose of the Test Sheets is described in Understanding The System. Hold a stack of five immediately in front of the Receiver lens.

Verify from the Handheld screen and from the control equipment that the complete system responds correctly, as if to gas. If the reading

is off scale, remove sheets one by one until it is on scale. Record the mean reading, together with the Serial Numbers of the Transmitter,

Receiver and Test Sheets for future reference. Recording the Test Sheet readings enables you to check subsequently that the response

to gas has not been affected in any way. You may also wish to introduce the Sheets one by one to check correct operation of the control

equipment at intermediate readings. If required, similar checks can be carried out with real gas using the Gas Check Kit GCK400.

CORRECTLY

ALIGNED

MISALIGNED

01623892.eps

ZERO

Loading...

Loading...