EPSON

PRINTERS

4.9.1

HP

SENSOR

Adjustment

Refer

to

Figure 4-11

and

4-12

1.

Remove

the

printer

lid

and

the

ribbon

cartridge.

2. Loosen

the

HP

Sensor

adjustment

screw.

3. Insert a thin flat tipped screwdriver into

the

notch

at

the

front

of

the

sensor

base

and

adjust

the

lateral position of

the

sensor. If

the

print margin

should

be

more

to

the

right

mover

the

sensor

to

the

right.

4.

Check

to

see

that

the

sensor

flag

(on

carriage)

does

not

contact

either

side of

the

sensor.

5. Reinstall

the

ribbon

and

perform

a

self

test.

Insurethat the printing beginsat the proper

margin position

(Fig.

4-12). If it

does

not

make

a

note

of

which

way

to

move

the

HP

Sensor repeat steps 1-4 until the desired

results

are

achieved.

HP.MniOfcircuitboird «mv

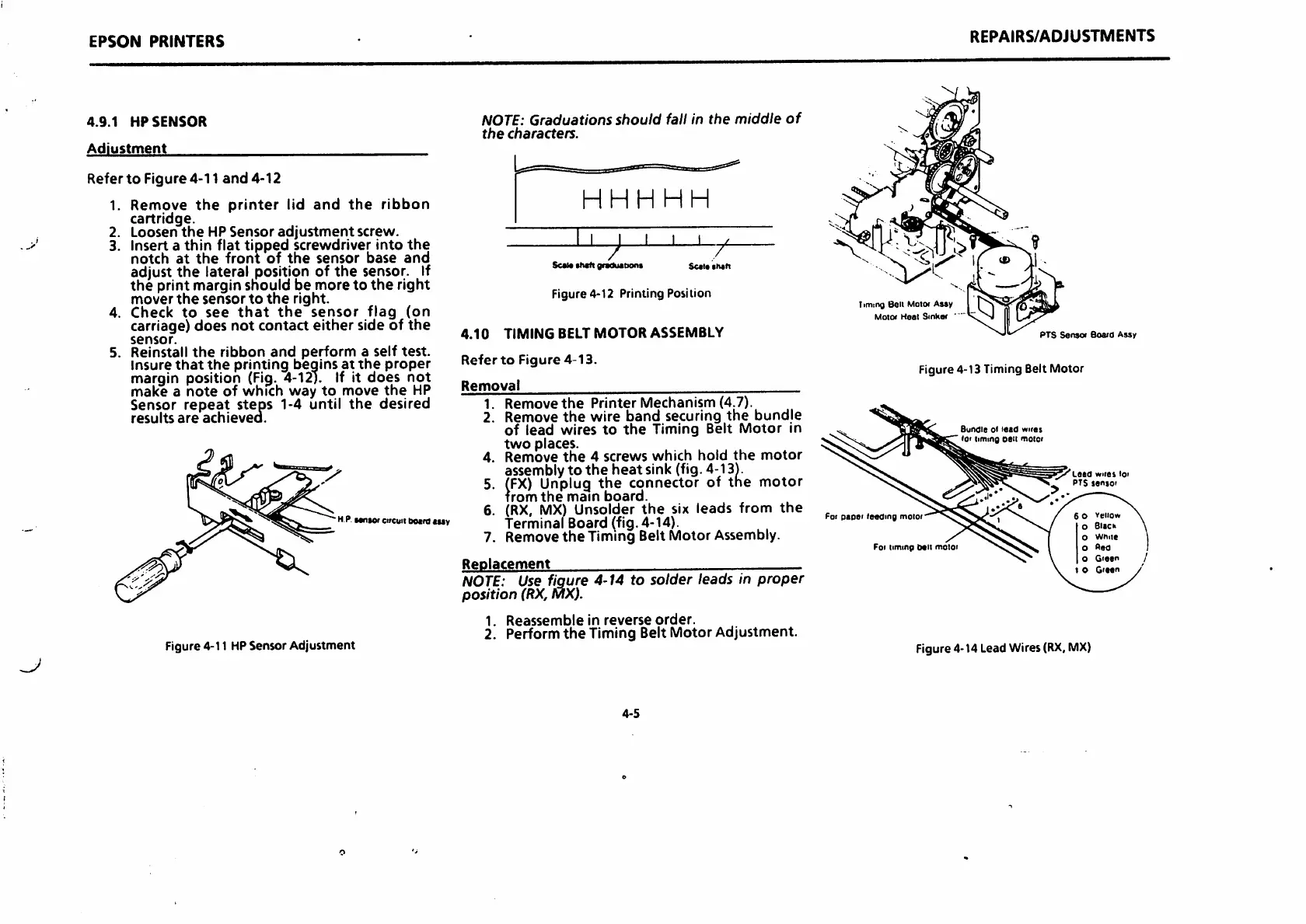

Figure 4-11 HPSensor Adjustment

NOTE:

Graduations

should

fall in

the

middle

of

the

characters.

HHH

HH

I I

ScM

e«*duation«

Figure 4-12 Printing Position

4.10

TIMING

BELT

MOTOR

ASSEMBLY

Refer

to

Figure

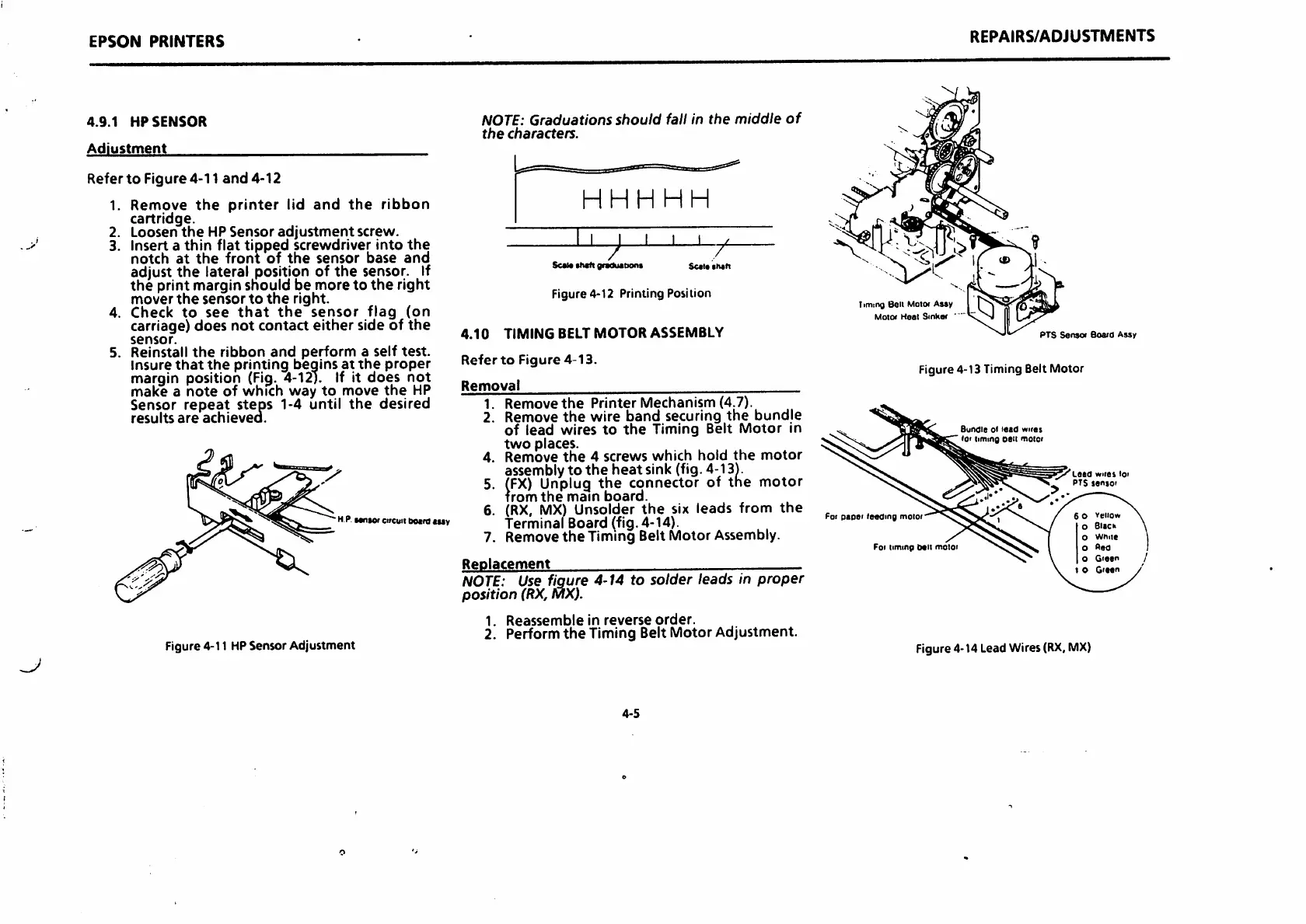

4-13.

Removal

1.

Remove

the

Printer

Mechanism

(4.7).

2. Remove

the

wire

band

securing

the

bundle

of

lead

wires

to

the

Timing Belt

Motor

in

two

places.

4.

Remove

the

4

screws

which

hold

the

motor

assemblyto

the

heat

sink (fig. 4-13).

5.

(FX)

Unplug

the connector of the motor

Trom

the

main

board.

6.

(RX,

MX)

Unsolder

the

six leads from

the

Terminal Board (fig. 4-14).

7. Remove

the

Timing Belt Motor Assembly.

Replacement

/

Sc«l«

th«fi

NOTE:

Use figure 4-14 to

solder

leads in

proper

position

(RX,

MX).

1.

Reassemble

in

reverse

order.

2. Perform

the

Timing Belt Motor Adjustment.

4-5

Timing Bell Motw Assy

Motw

Heal

Sinhaf

REPAIRS/ADJUSTMENTS

PTS

Sense

Boaid

Assy

Figure 4-13 Timing Belt

Motor

r

leading

I

iimmp

Bundle

iimmg

Lota

wiiet

loi

PTS

jsnjoi

veiiow

eiick

Wnue

o

Red

Gie«r

1 O

Gitan

Figure4-14 LeadWires

(RX,

MX)

Loading...

Loading...