c

Important:

Do not hang hanger platens on the hooks. They

could fall on the floor and be damaged.

Depending on the type of frame, only hang one as shown

in the illustration.

❏ Frames for L/M size hanger platens and

medium grooved platens

❏ Frames for S size hanger platens

❏ Frames for XS size platens as well as sleeve

platens

Loading on Sleeve Platens

A

Press the P button to turn on the printer.

B

Check that the platen is ejected forward.

If it is not ejected, press the } button to move the

platen forward.

C

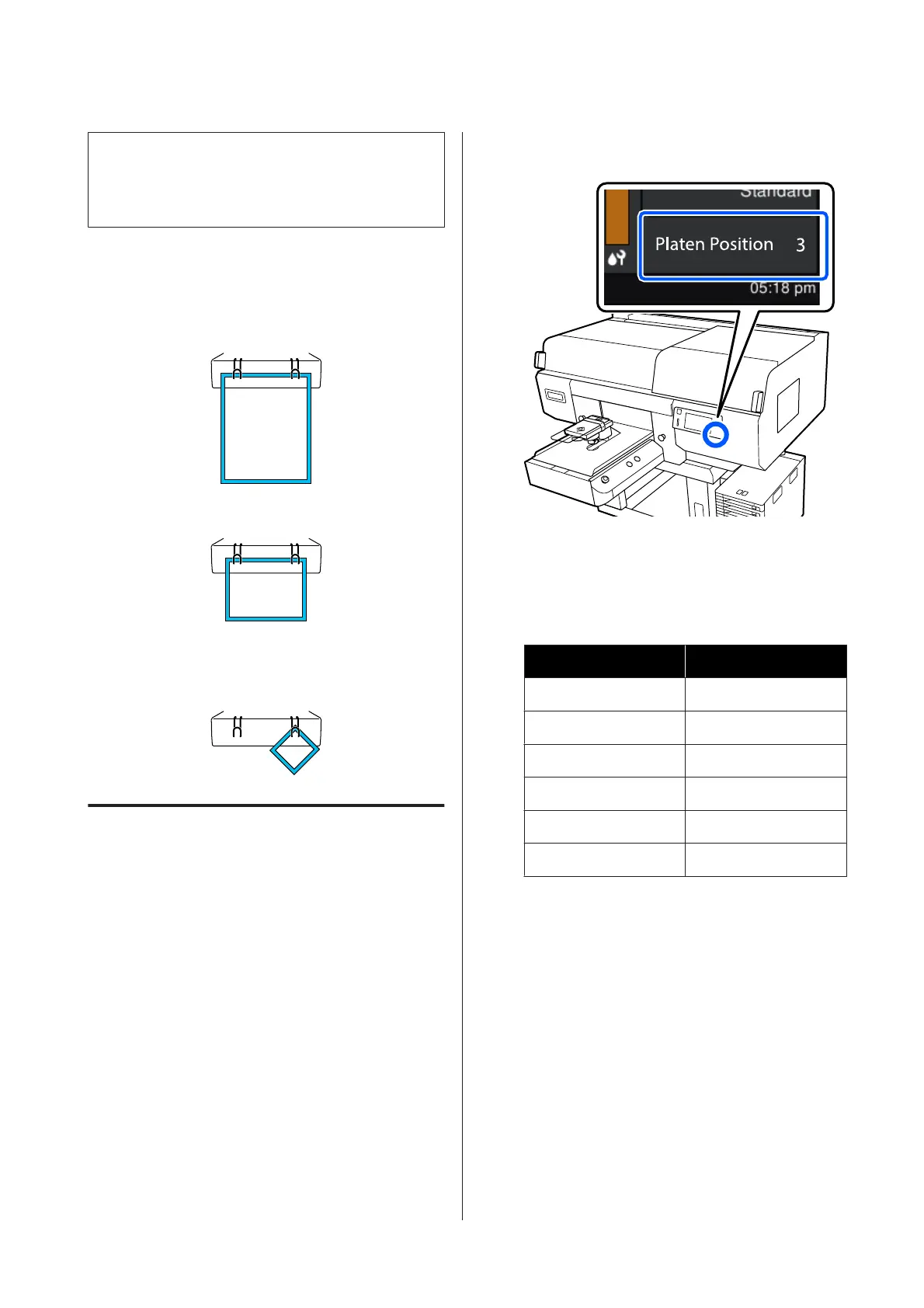

On the printer's screen, confirm that the platen

position is as shown below.

When Platen Gap is set to Auto:

The optimum platen position varies depending

on the thickness of the media. Use the following

guideline to change the platen position.

Media thickness Platen position

0 mm to 4 mm 3

4 mm to 7 mm 4

7 mm to 10 mm 5

10 mm to 13 mm 6

13 mm to 16 mm 7

16 mm to 19.5 mm 8

When Platen Gap is set to Manual:

The optimum platen position varies depending

on the thickness of the media being loaded and

the type of platen being used. See the following

for more details.

U “Table for Platen Gap setting values for

media thicknesses” on page 142

See the following for how to change the platen

position.

U “How to change the platen position” on

page 58

SC-F3000 Series User's Guide

Basic Printing

65

Loading...

Loading...