76

*) (1/F-P = time interval between two pulses)

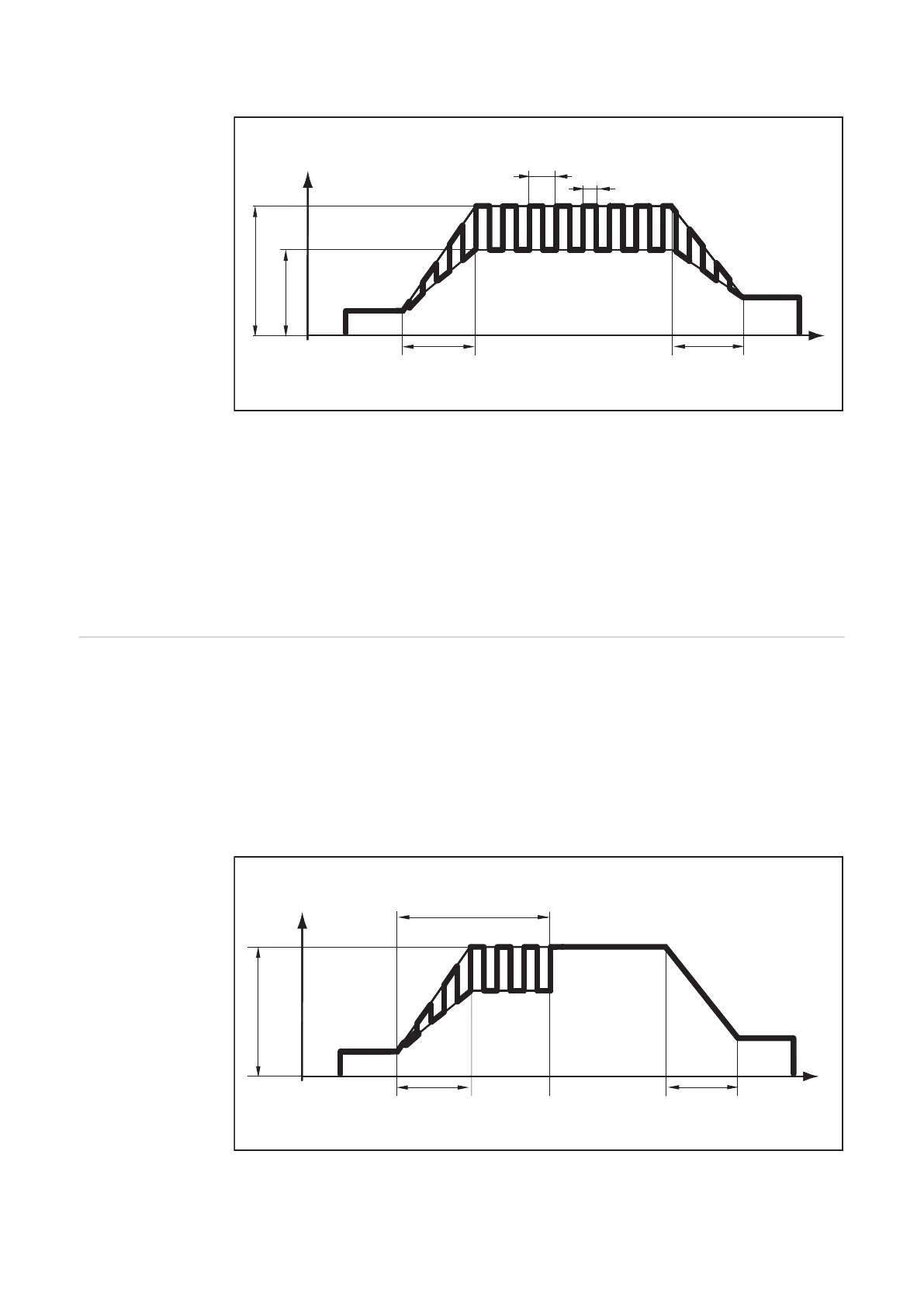

Tacking function The tacking function is available for the TIG DC welding process.

When a time period is specified for the tAC (tacking) setup parameter, the tacking function

is assigned to 2-step mode and 4-step mode. The operating sequence of the modes re-

mains unchanged.

During this period, a pulsed welding current is present that makes the weld pool run togeth-

er better when two parts are being tacked.

Mode of operation of tacking function when the TIG DC welding process is selected:

Tacking function - welding current curve

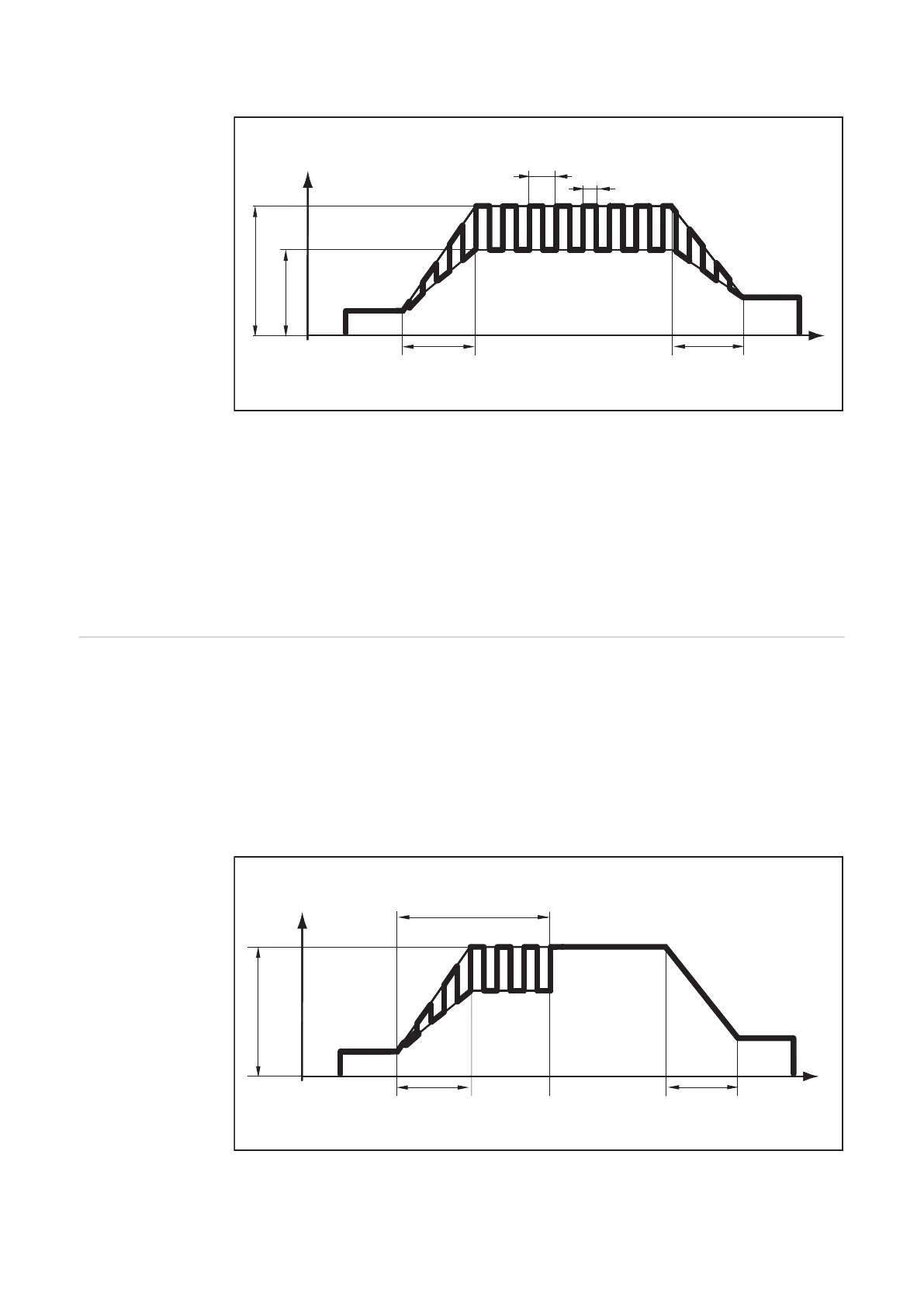

Mode of operation of TIG pulsing when TIG DC welding is selected:

TIG pulsing - welding current curve

Legend:

I

S

Starting current F-P Pulse frequency *)

I

E

Final current dcY Duty cycle

t

up

Upslope I-G Ground current

t

Down

Downslope I

1

Main current

1/F-P

I

1

I-G

I

t

t

up

t

down

I

S

I

E

dcY

Loading...

Loading...