192 AK 98™ Dialysis Machine - Maintenance manual

HCEN12630 Revision 07.2015

Program version 1.xx

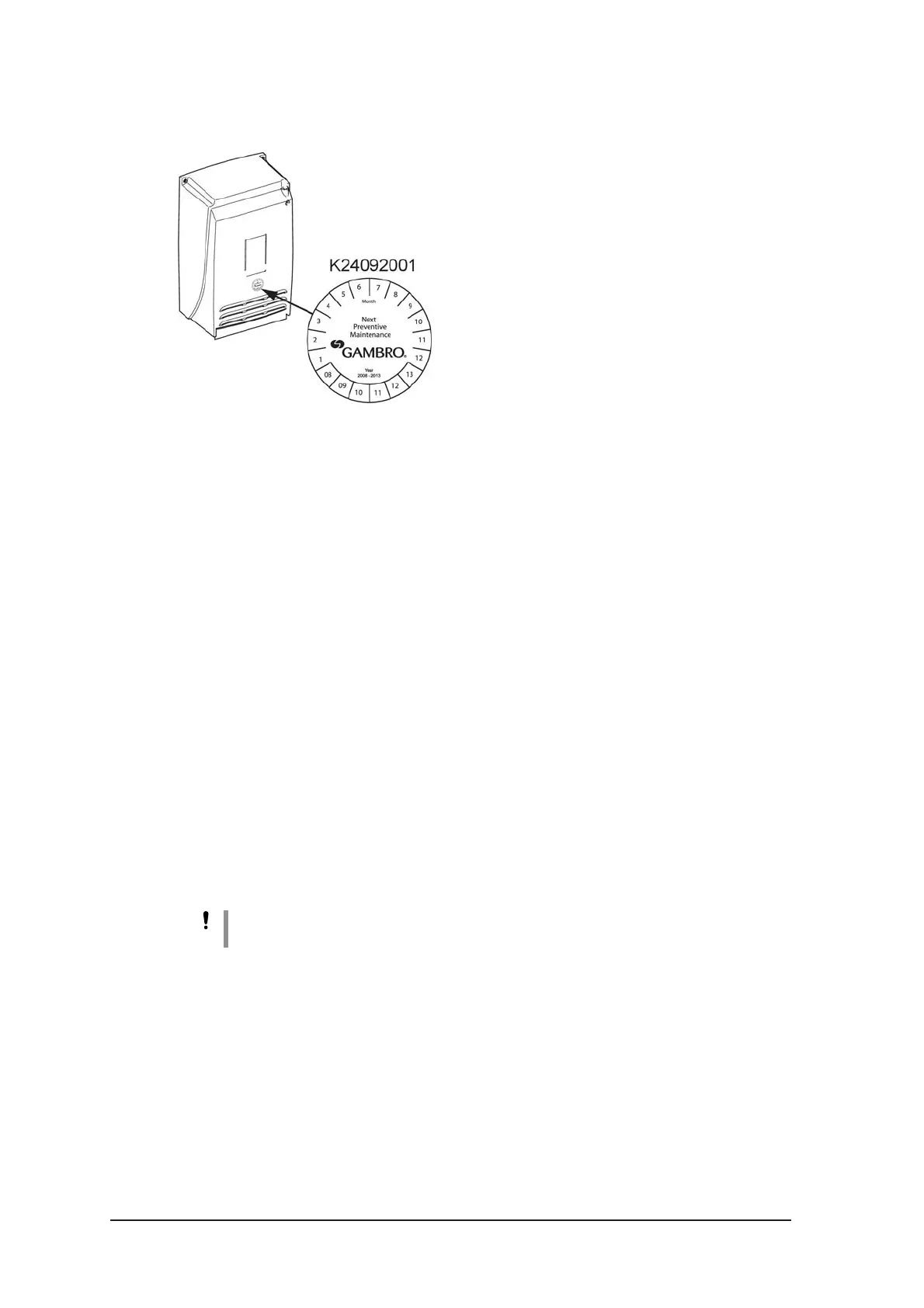

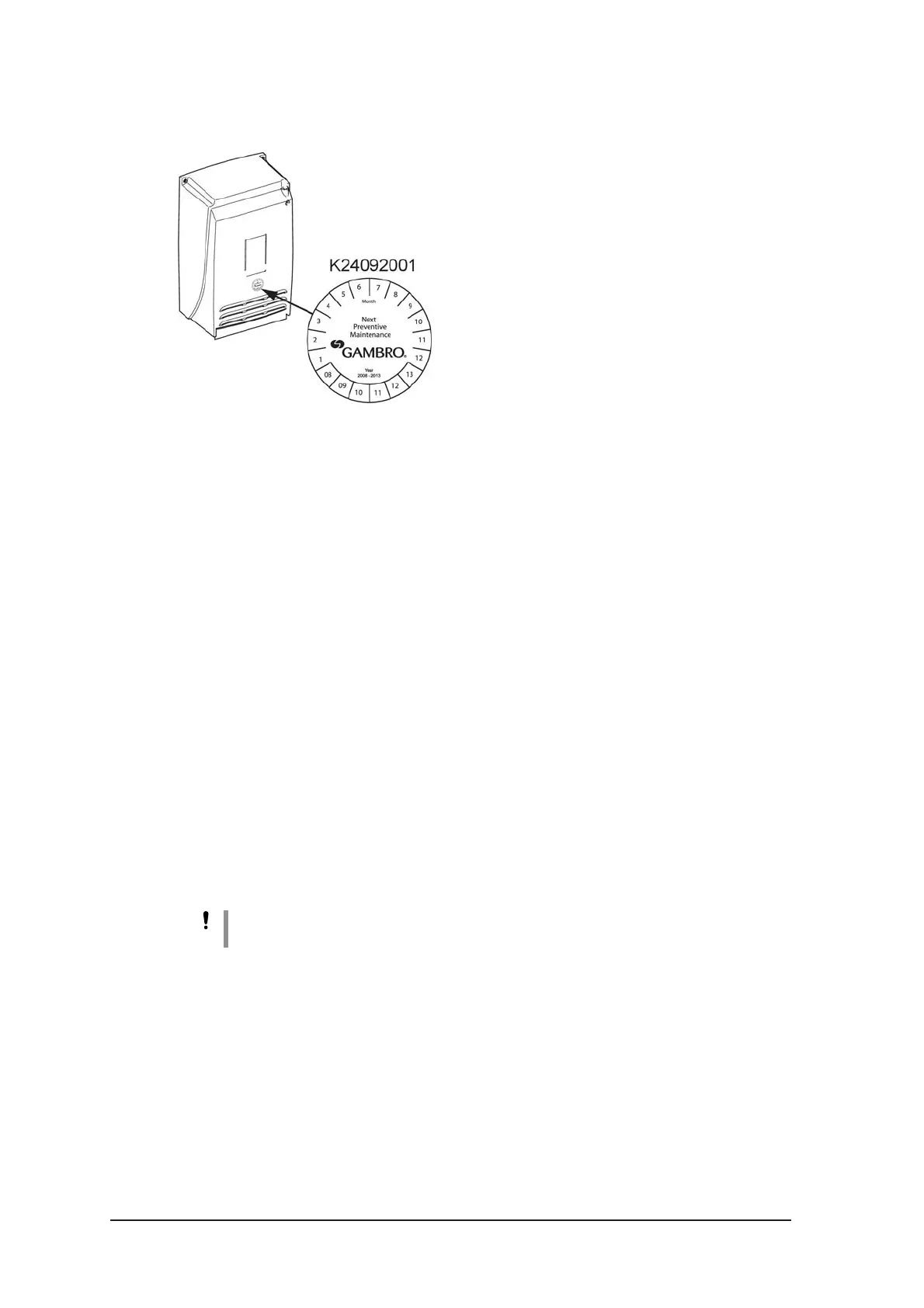

15) Mark month and year for the next

scheduled preventive maintenance. Attach

the label to the rear cover of the machine.

8.4.3 Actions to carry out after the parts in the Base-kit have been

exchanged

Procedure

1) Check that the screws for the blood pump are tightened. (Both inside the BM and

behind the blood pump rotor).

2) Check that the screws for the hose clamps on the water inlet and drain tube are

tightened.

3) Check that the wheels are tightened.

4) Perform the Protective Earth Test (PET) according to instructions available in

Section 9 “Electrical safety inspection” on page211.

5) If connected, disconnect the cable K64897/K68678 (on RP 98) from the connector

P202.

6) If connected, disconnect the cable K67217/K68679 (on RP 98) from the connector

P203 on the display card K67455.

7) Check the protective earth resistance: Measure between TP594 (Z0VL) on the

power I/O board and the metal on the heater rod.

Measure in MΩ, should be > 1 MΩ. The machine shall be empty and switched off

during measurement.

NOTE!

Place the blood monitor on the fluid monitor.

8) Reconnect the cable K64897/K68678 (on RP 98) to the connector P202.

9) Reconnect the cable K67217/K68679 (on RP 98) to the connector P203 on the

display card K67455.

10) BPM-test

(Only for the AK 98 dialysis machine equipped with BPM)

a) BPM sub-tests

● Air leakage test: measures that the equipment is airtight.

● Pressure test: Check of pressure transducer calibration.

● Inflation speed test: measures the time to fill the cuff with air.

Loading...

Loading...