GFC 600 AFCS Part 23 AML STC Maintenance Manual Page 16

190-01938-00 Revision 13

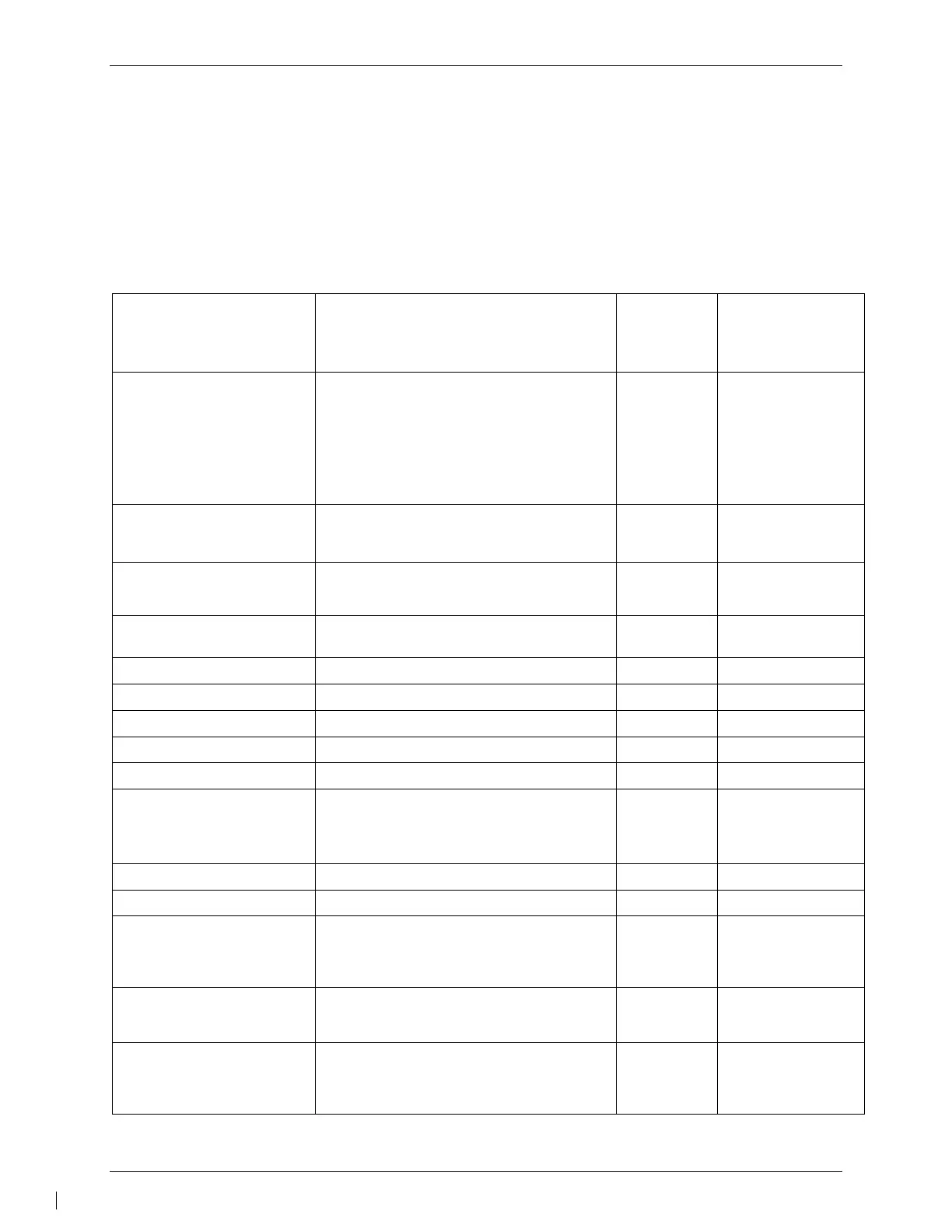

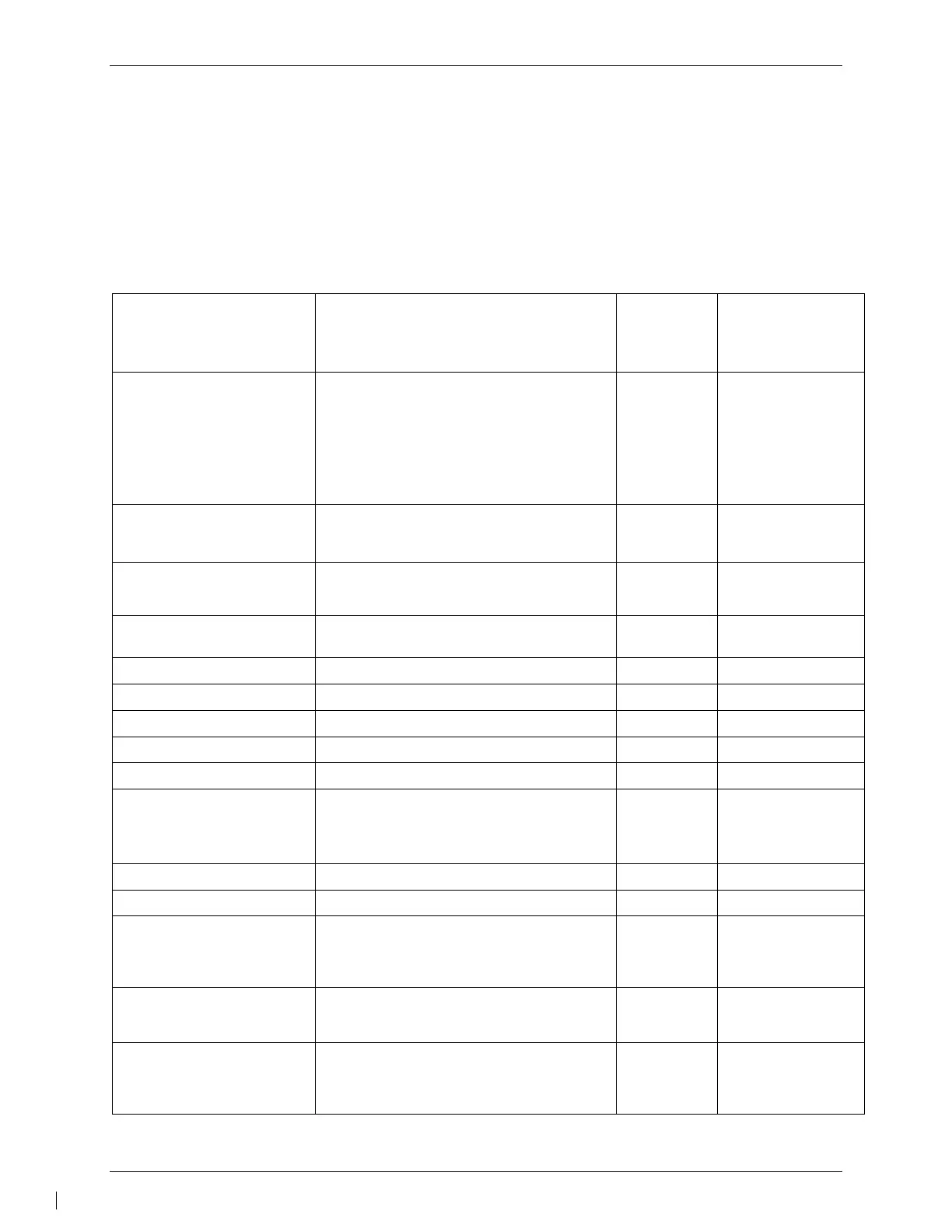

4.3 Maintenance Intervals

Table 4-1 shows systems and items, installed by this STC, which must undergo tests or checks

at specific intervals. If the interval is shown to be in flight time as well as calendar months, the

first interval reached should be used as the limit.

Those inspections that are based on flight time or calendar elapsed time or cycles shall have

specific intervals stated in Table 4-1.

Those inspections that are listed as special do not align with annual or phase inspections.

Table 4-1 – Maintenance Intervals

Equipment electrical Bonding

Test

Verify bonding of GMC 605 rack, GI 285 rack

(if installed), GSA 87, GSA 80/81, and GSM

86 mounting brackets, GTA 82, and any

associated bonding components

Following removal

and replacement of

the racks or brackets

AND

Every 2000 flight

hours or ten years,

whichever is first

Equipment Bonding Visual

Inspection – suspected

lightning strike

Inspection of bonding Components

At any suspected or

actual lightning

strike

GFC 600 Equipment Visual

Inspection

Visual inspection of GFC 600 components

At every annual

inspection

Sonalert Disconnect Tone

Check (if installed)

Functional test of Sonalert

At every annual

inspection

GMC 605 Autopilot Computer

GI 285 Autopilot Annunciator

Servos, Servo Control

Cables/Chains and

associated hardware

With aircraft

manufacturer’s

required primary

control cable checks

GSM 86 Servo Gear Box (all)

GSM 86 Servo Gear Box

Slip Clutch Torque Check *

For installations with the GSM 86 servo gear

box, verify that the pitch, roll, yaw and pitch

trim GSM 86 slip clutch torque values are

within acceptable limits

GSM 86 Servo Gear Box

Clutch Disengagement

Check *

For installations with the GSM 86 servo gear

box, verify that the pitch, roll, yaw and pitch

trim GSM 86 clutch disengages

GSA 87 Yaw Trim Servo AP

DISC/TRIM INT Switch

Check *

For installations with a GSA 87 yaw trim

servo, verify that the yaw trim servo

disengages when the AP DISC/TRIM INT

Switch is pressed

Every 400 Hours or

annual inspection,

whichever is first

* Denotes Airworthiness Limitation Maintenance Requirement (See Section 4.1)

Loading...

Loading...