55 • Starting Procedure

Continued from previous page

6.2 Examples of Starting Curves

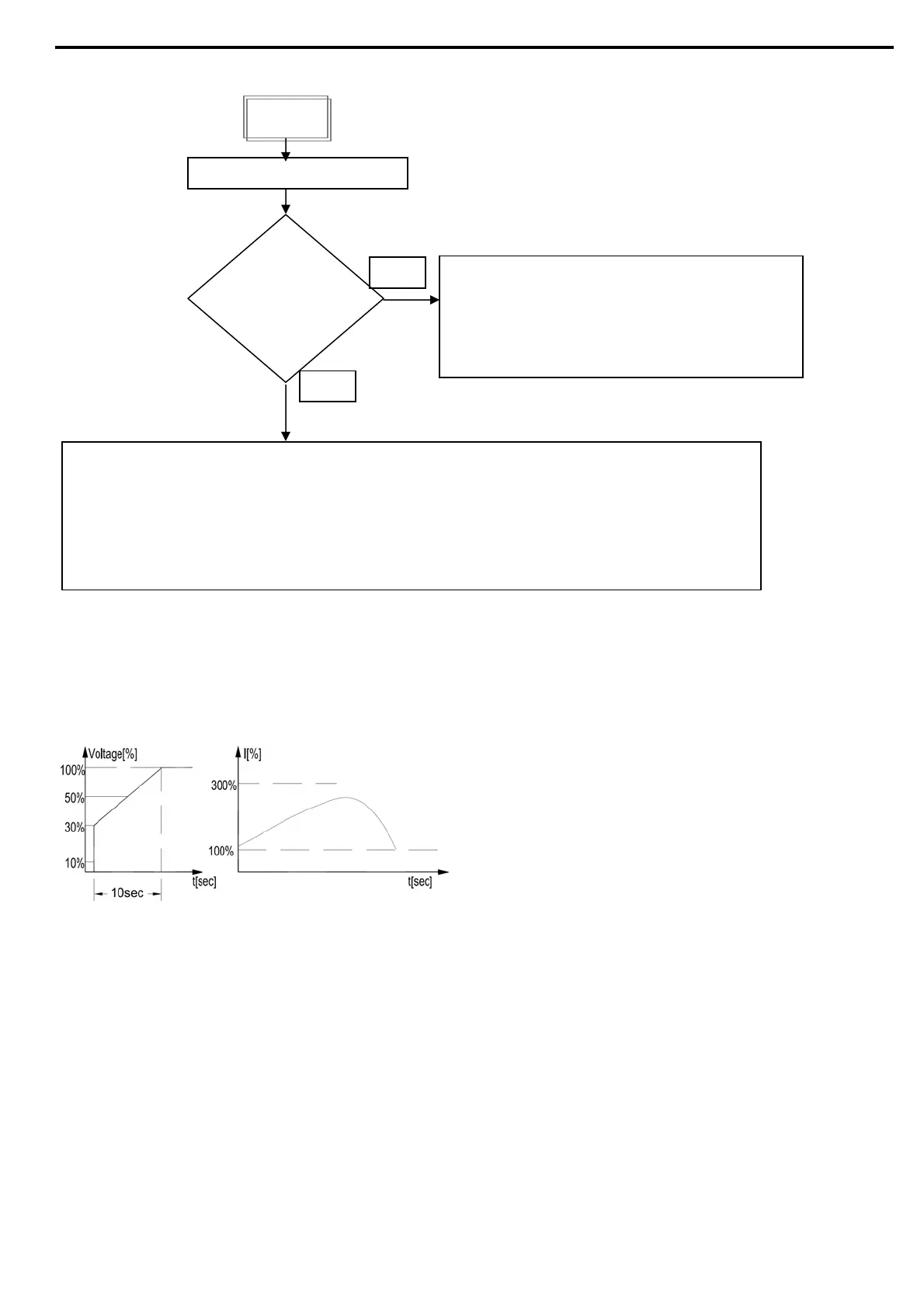

6.2.1 Light Loads - Pumps, Etc.

(In these cases the actual current is always lower than the Current Limit setting)

Starting Voltage- set to 30%

Current Limit - set to 300-350%

Ramp UP Time- set to 10 sec.

Upon start, the voltage quickly increases to the Starting Voltage value (30% of Un) and then gradually ramps-

up to nominal.

The current will simultaneously increase to peak current value (lower than the Current Limit setting), before

smoothly decreasing to the operating current.

6.2.2 High Inertia Loads: Crushers, Centrifuges, Mixers, Etc.

(In these cas

es the actual current is at the CURRENT LIMIT setting during part of the starting time)

Starting Voltage– set 40%

Current Limit– set 400%

Ramp UP Time– set 3 sec

• Check Last Start Time and set Max. Start time to approximately 5 seconds

longer than the Last Start Time.

• For future reference it is advised to keep records of the following parameters in the

Statistical Data:

Last Start Time:

Last Start Curr.:

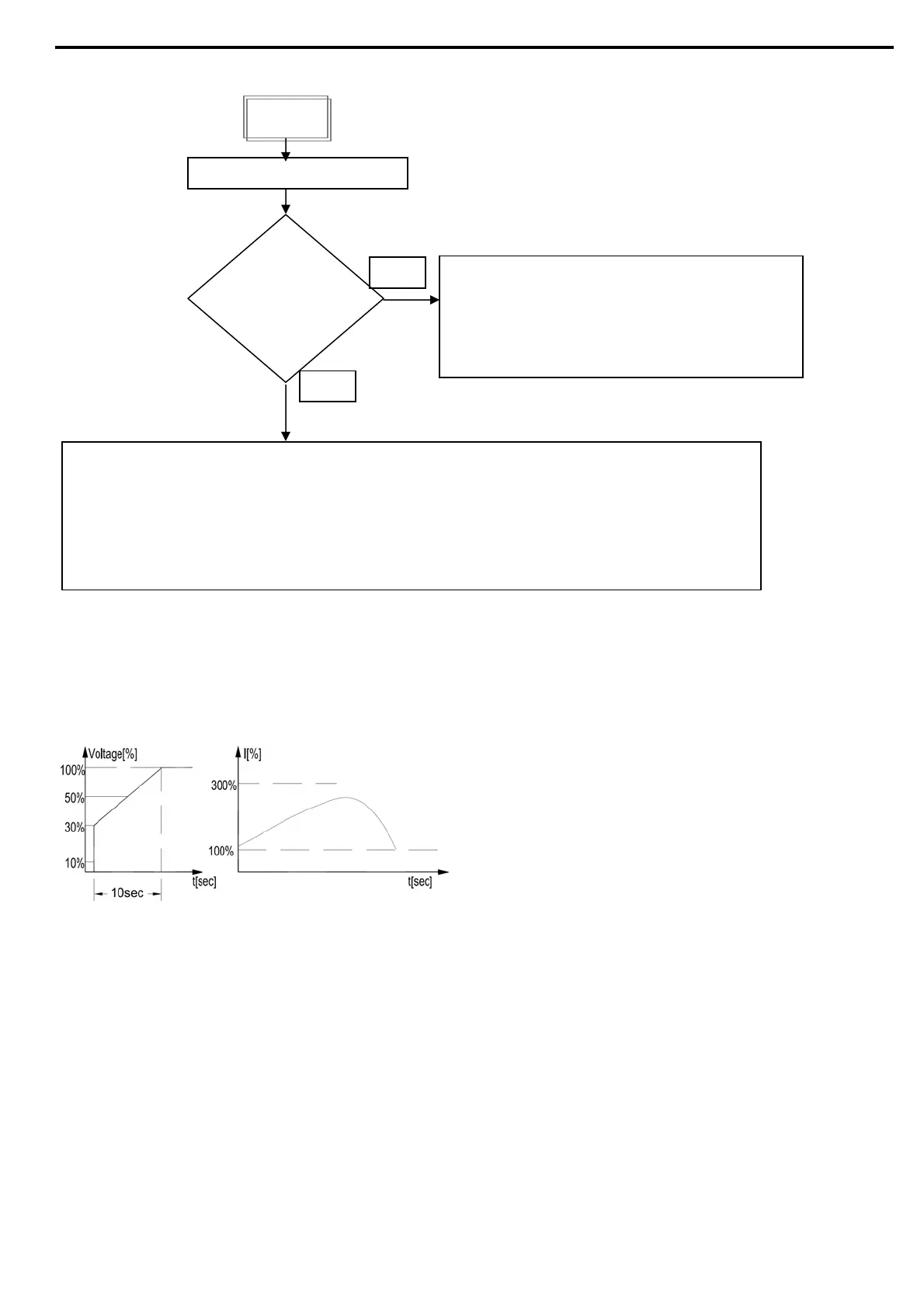

Motor acceleration

time to full speed is

as re

uired?

No

Yes

If acceleration time is too short, increase Ramp

UP Time setting and/or decrease Current

Limit setting (when decreasing Current

Limit, make sure that the motor increases

speed gradually and does not stall).

A

A

l

the START command

Loading...

Loading...