What to do if my GE Controller indicates Access Locked?

- IicarterAug 21, 2025

If your GE Controller indicates 'Access Locked', and you need to change parameters, verify that dip switch #8 is set to OFF.

What to do if my GE Controller indicates Access Locked?

If your GE Controller indicates 'Access Locked', and you need to change parameters, verify that dip switch #8 is set to OFF.

What to do if my GE Controller shows an Overload?

If the GE Controller indicates an overload, it means the current exceeds the Overload Trip level and the thermal register has filled up. Check the Motor Current and Starter Current settings, as well as the overload settings. Also, check the motor current. Allow at least 15 minutes for the motor and ASTAT-XT to cool down before attempting to restart.

What to do if my GE Controller displays O/C JAM Fault?

If you're seeing an O/C JAM Fault on your GE Controller, first check that the motor is not stalled or jammed. Then, verify the Motor Current and Starter Current settings. Inspect the motor and cable connections. Perform a “Megger” test to verify the condition of the motor and cable.

What does it mean when my GE ASTAT XT QT 0008U shows Undervoltage?

An Undervoltage indication on your GE Controller means the line voltage has dropped below the preset level for the preset time. You should check the Undervoltage FLT and Undervoltage DLY settings and also check the line voltages on L1, L2, and L3.

What does it mean when my GE ASTAT XT QT 0008U displays Overvoltage?

If your GE Controller is showing Overvoltage, it means the line voltage has increased above a preset level for a preset time. Check the Overvoltage FLT and Overvoltage DLY settings, and verify the line voltage on L1, L2, and L3.

How to troubleshoot Long Start Time on GE ASTAT XT QT 0008U?

If the GE Controller shows a Long Start Time, it means the output voltage does not reach nominal at the preset Max. Start time. Check the Starter Current and Max. Start Time settings. Increase the Starting Voltage, Current Limit, and Max. Start Time or decrease the Ramp UP Time as necessary.

What causes Phase Loss on a GE Controller?

Phase Loss on a GE Controller indicates that one or two phases are missing. If you're using ASTAT-XT 9501400A models with externally connected current transformers, verify that the current transformers are not grounded. Check the phase voltages related to terminal 21 and ensure that terminal 21 is connected correctly.

What does it mean when my GE ASTAT XT QT 0008U Controller displays Undercurrent FLT?

The Undercurrent FLT on your GE Controller indicates that the line current has dropped below the preset level for the preset time. Verify the Undercurrent FLT and Undercurrent DLY settings, and check the line currents of L1, L2, and L3.

What to do if my GE Controller shows Over Temperature?

If your GE Controller displays an Over Temperature warning, it means the heat-sink temperature has risen above 85°C. You can improve cooling or use a bypass contactor. Make sure that motor starting is not too frequent.

What to do if my GE Controller indicates 'Too Many Starts'?

If the GE Controller indicates 'Too Many Starts', allow the motor and ASTAT-XT to cool down, considering the Number Of Starts, Duty Cycle Time, and Start Lockout settings.

| Current Rating | 8 A |

|---|---|

| Series | ASTAT XT |

| Phase | 3 |

| Enclosure | Open |

| Mounting | DIN Rail |

| Certifications | UL, CSA, CE |

Essential safety instructions and operational cautions for the ASTAT-XT soft starter.

Explanation of starting limitations and the benefits of soft starting for squirrel-cage motors.

Key benefits of using ASTAT-XT, including productivity, reliability, and advanced functions.

Table of recommended motor ratings based on IEC voltage and duty class for ASTAT-XT soft starters.

Table of recommended motor ratings based on NEMA voltage and duty class for ASTAT-XT soft starters.

Graphs illustrating thermal protection curves for different IEC and NEMA overload classes.

Overview of electrical, environmental, and mechanical specifications for the ASTAT-XT soft starter.

Details on ASTAT-XT weight and the functions of its I/O terminal board.

Schematic illustrating input/output connections for the ASTAT-XT soft starter.

Guide for selecting ASTAT-XT models and ordering related accessories like mounting kits.

Description of various operating modes for the ASTAT-XT, including starting and stopping curves.

Explanation of the ASTAT-XT control keypad, LCD, and push-buttons.

Procedure for navigating, viewing, and changing parameters on the ASTAT-XT using the control keypad.

Instructions for performing self-tests, viewing software versions, and obtaining default parameters.

Explanation of how to navigate through different ASTAT-XT parameter pages using the Mode key.

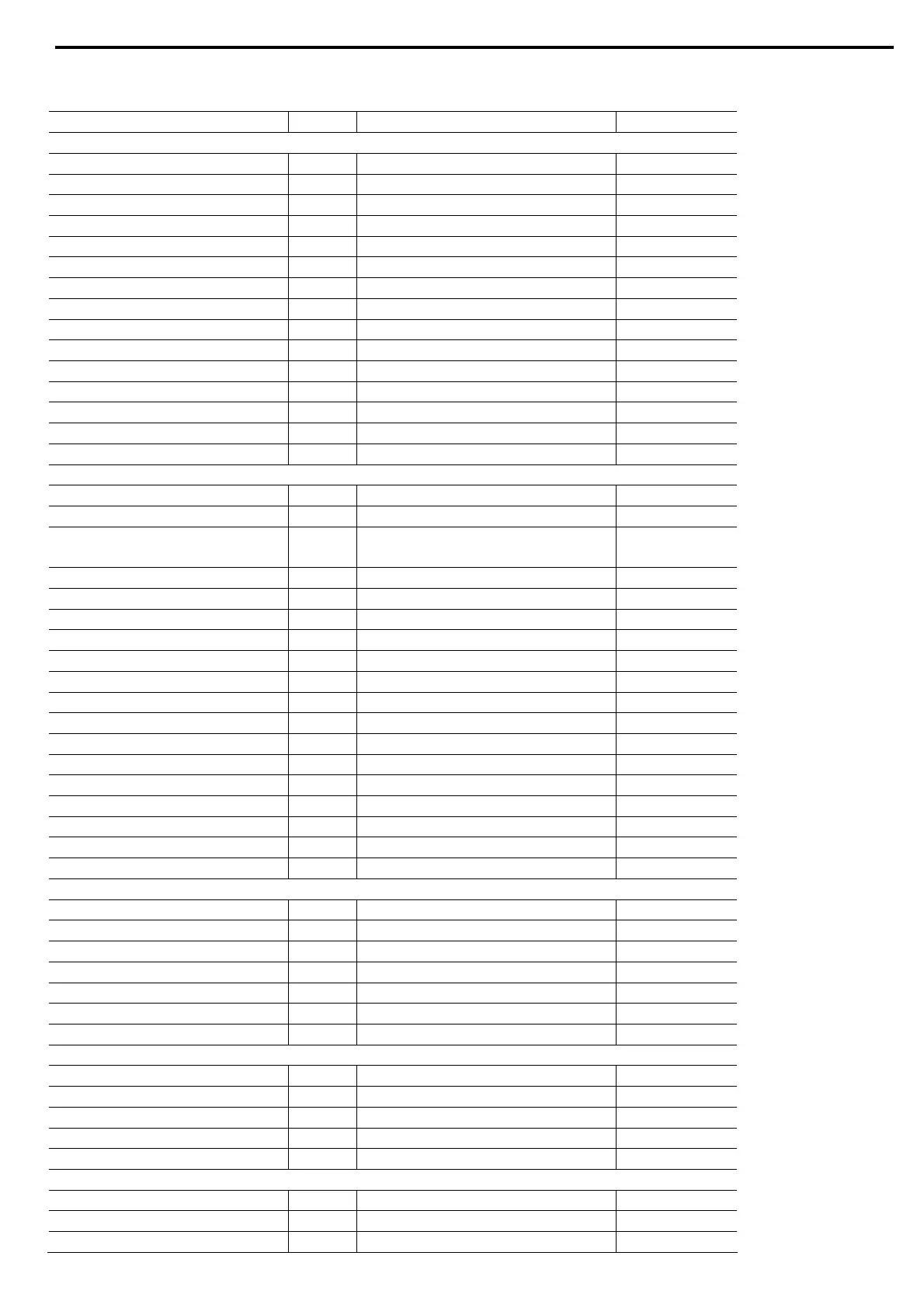

Overview table of ASTAT-XT mode pages and their default parameter values.

Details on the ASTAT-XT's default display page showing motor current, line voltage, and thermistor input.

Configuration of primary ASTAT-XT settings including starter current, motor current, and protection levels.

Configuration of soft start curves, kickstart time, and starting voltage/current for ASTAT-XT.

Detailed explanation of the five available soft start curves for the ASTAT-XT.

Configuration of soft stop curves, ramp down time, and end torque for ASTAT-XT.

Description of the five soft stop curves, including standard and pump control options.

Settings for dual operating characteristics, including starting voltage and current for different conditions.

Configuration of energy saving levels and slow speed torque settings for the ASTAT-XT.

Configuration of protective functions like phase loss, phase sequence, and auto reset for the ASTAT-XT.

Configuration of programmable inputs, fault relay, and analog output settings for the ASTAT-XT.

Details on programming functions for input terminals 7 and 8, including Reset, Slow Speed, and Dual Settings.

Configuration of communication parameters for Modbus and Profibus protocols on the ASTAT-XT.

Configuration of communication parameters for DeviceNet protocol on the ASTAT-XT.

Information on recorded statistical data, including start times, run times, and fault history.

Non-adjustable protection features like frequency, phase loss, and SCR short circuit.

Description of non-adjustable protection features like frequency, phase loss, and SCR short circuit.

Explanation of how ASTAT-XT handles faults, LED indications, and local/remote reset methods.

Details on auto-reset functionality for specific faults and a table showing fault occurrence timing.

Guidelines for checking motor/starter compatibility, mounting the ASTAT-XT, and temperature considerations.

Information on operating temperature limits, heat dissipation calculations, and ventilation for ASTAT-XT.

Diagrams showing main PCB locations and identification of optional PCBs and fan jumpers.

Explanation of dip switch functions for display modes, generator parameters, language, and expanded settings.

Configuration of internal fan operation and analog I/O functions, including thermistor input and output.

Instructions for installing the optional remote key-pad, including dimensions and connection.

Important warnings and notes regarding motor connections, voltage, and starting sequence for the ASTAT-XT.

Step-by-step guide for performing a standard motor start-up and troubleshooting common starting issues.

Examples of ASTAT-XT starting curve settings for light loads, high inertia loads, and pump applications.

Procedure for using dual starting characteristics with ASTAT-XT for specific motor acceleration needs.

Wiring diagram for DUAL settings and guidance on selecting suitable pump start curves.

Guidelines for selecting stopping curves and adjusting end torque to prevent water hammer in pump applications.

Troubleshooting common ASTAT-XT faults like storage error, access lock, thermistor trip, and overload.

Troubleshooting procedures for faults related to voltage, phase loss, sequence, and connection issues.

Resolving issues with wrong connections, shorted SCRs, over-temperature, and parameter transfer.

Diagrams showing terminal 21 connections for various mains types and control supply wiring.

Wiring configurations for control supply and mains, including separate source options.

Wiring examples for soft start, soft stop, and immediate stop functions using various control inputs.

Application diagrams for energy saving, slow speed, and reset functions using input terminals.

Wiring for external fault input and typical installation with a line contactor for ASTAT-XT.

Diagram showing the wiring for a bypass contactor, including end-of-ramp relay control.

Wiring diagram for reversing motor direction using two line contactors with the ASTAT-XT.

Instructions for operating the ASTAT-XT via Modbus, Profibus, or DeviceNet communication interfaces.

Configuration for starting the ASTAT-XT from a diesel generator using D.Set: Generator Parameters mode.

Tables for selecting circuit breakers and fuses for Type 1 coordination with ASTAT-XT.

Procedure for selecting fuses for semiconductor protection based on ASTAT-XT current and I²t values.

Explanation of Inside Delta connection, current reduction, and potential issues like THD and phase sequence.

Details on motor terminal connections for Inside Delta configuration and wiring standards.

Wiring diagram for ASTAT-XT connection Inside Delta with bypass and Inside Delta contactors.

Wiring diagram for reversing motor speed with ASTAT-XT connected Inside Delta.

Dimensional drawings and specifications for UL cUL approved ASTAT-XT models (8A to 460A).

Dimensional drawings and specifications for non UL cUL approved ASTAT-XT models (210A to 1400A).

Overview of the serial link protocol used for communication between a master and the ASTAT-XT.

Explanation of Modbus RTU frames, sync, serial link number, and supported functions.

Explanation of Modbus data fields, CRC calculation, and ASTAT-XT memory organization.

Mapping of actual data parameters like voltage, current, and logic status to Modbus 3X and 4X references.

Table detailing ASTAT-XT parameters, their ranges, default values, and Modbus 4X references.

Procedure for writing to the ASTAT-XT's control register using Modbus function 16.

Explanation of discrete commands (coils) for controlling ASTAT-XT functions like Stop, Start, and Energy Save.

Description of discrete hardwired inputs for ASTAT-XT functions like Stop, Start, and Energy Save.

Procedure for performing Modbus diagnostics (loopback) on the ASTAT-XT.

Explanation of Modbus exception codes returned by the ASTAT-XT for error conditions.

Description of PROFIBUS modes, receiving/transmitting frames, and register selection.

Procedure for reading and writing registers using PROFIBUS Data Request (DPV1).

Step-by-step guide to configure PROFIBUS communication settings on the ASTAT-XT.

Explanation of the Watch-Dog mechanism for monitoring PROFIBUS communication with the ASTAT-XT.

Table of decimal register numbers for actual data parameters in PROFIBUS communication.

Table listing PROFIBUS register numbers for ASTAT-XT setting parameters.

Overview of DeviceNet data types and definitions, reference documents, and ODVA.

Configuration of DeviceNet MAC ID/baud rate and explanation of LED indicators.

Details of DeviceNet Identity Object attributes and the Message Router Object.

Attributes for Assembly, Output, and Input Objects in DeviceNet for controlling and monitoring ASTAT-XT.

Details of the DeviceNet Connection Object and common services for attribute access.

Attributes and services for Softstart and Control Supervisor Objects in DeviceNet.

Attributes and services for the Modbus/Serial Object in DeviceNet, including slave ID and timeout settings.

Attributes and Modbus addresses for the Input Object in DeviceNet, covering logic status and motor parameters.

Attributes and Modbus addresses for the Main Parameter Object in DeviceNet, covering starter and motor settings.

Attributes and Modbus addresses for Start and Stop Settings Objects in DeviceNet.

Attributes and Modbus addresses for the Dual Settings Object in DeviceNet, for secondary start/stop parameters.

Attributes and Modbus addresses for Slow Speed/Saving and Fault Settings Objects in DeviceNet.

Attributes and Modbus addresses for I/O Settings and Communication Parameter Objects in DeviceNet.