PACE Pressure Controller User Manual

[EN] English 2 - 5 K0443 Revision A

Supply equipment

Pneumatic supplies should have isolation valves and, where necessary, conditioning

equipment.

The positive pressure supply should be regulated to between 110% of the full-scale pressure

range and MWP stated on the control module.

To protect the instrument from over-pressure a suitable protection device (such as a relief

valve or bursting disc) must be fitted to prevent over pressurization.

On instruments without a negative supply, the positive pressure discharges from the system

to atmosphere through the negative supply port. Pipe the negative port to a safe discharge

area or fit a diffuser to the negative port.

During system pressure vent operations, the pressure discharges from the system to

atmosphere through the negative and vent ports. Pipe both ports to a safe discharge area or

fit a diffuser to the negative port.

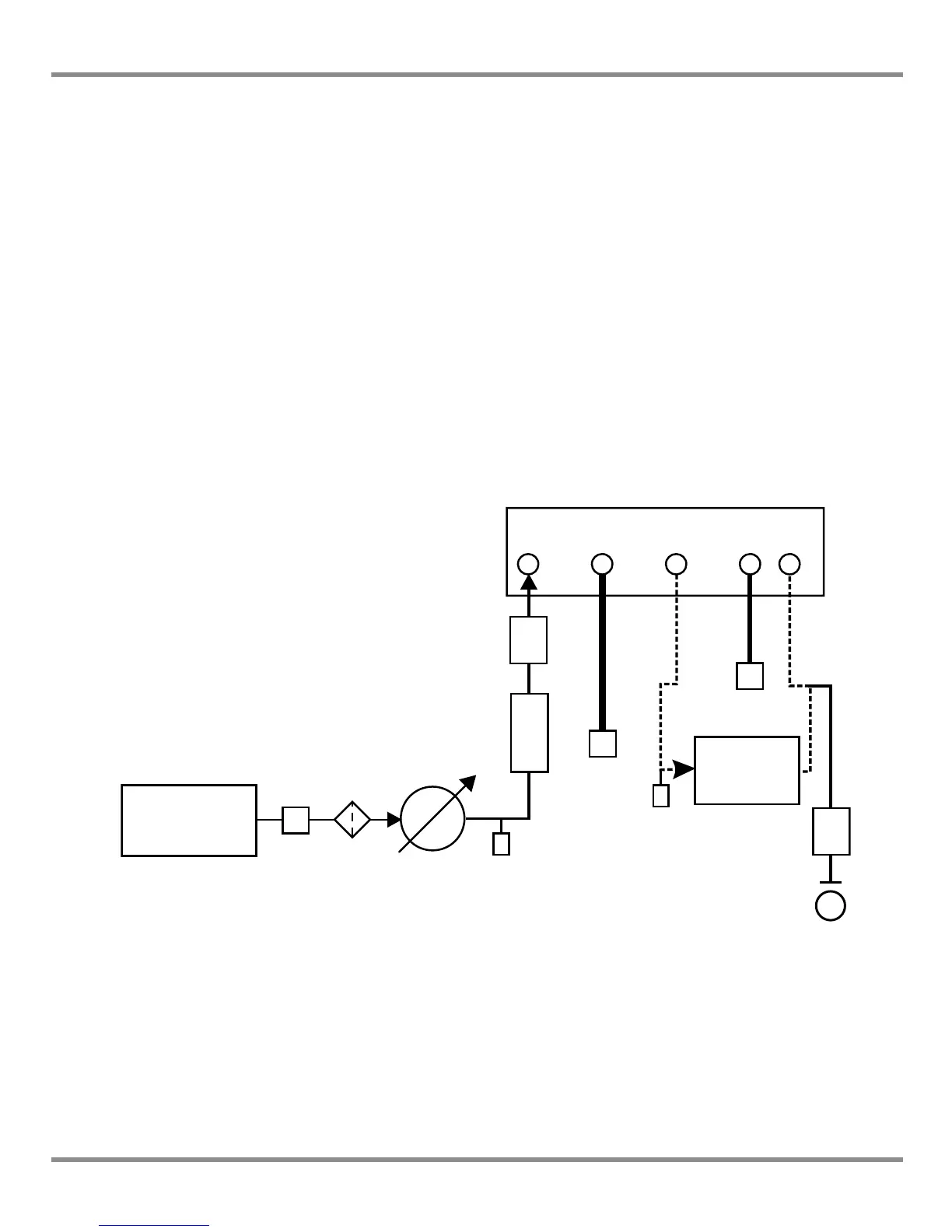

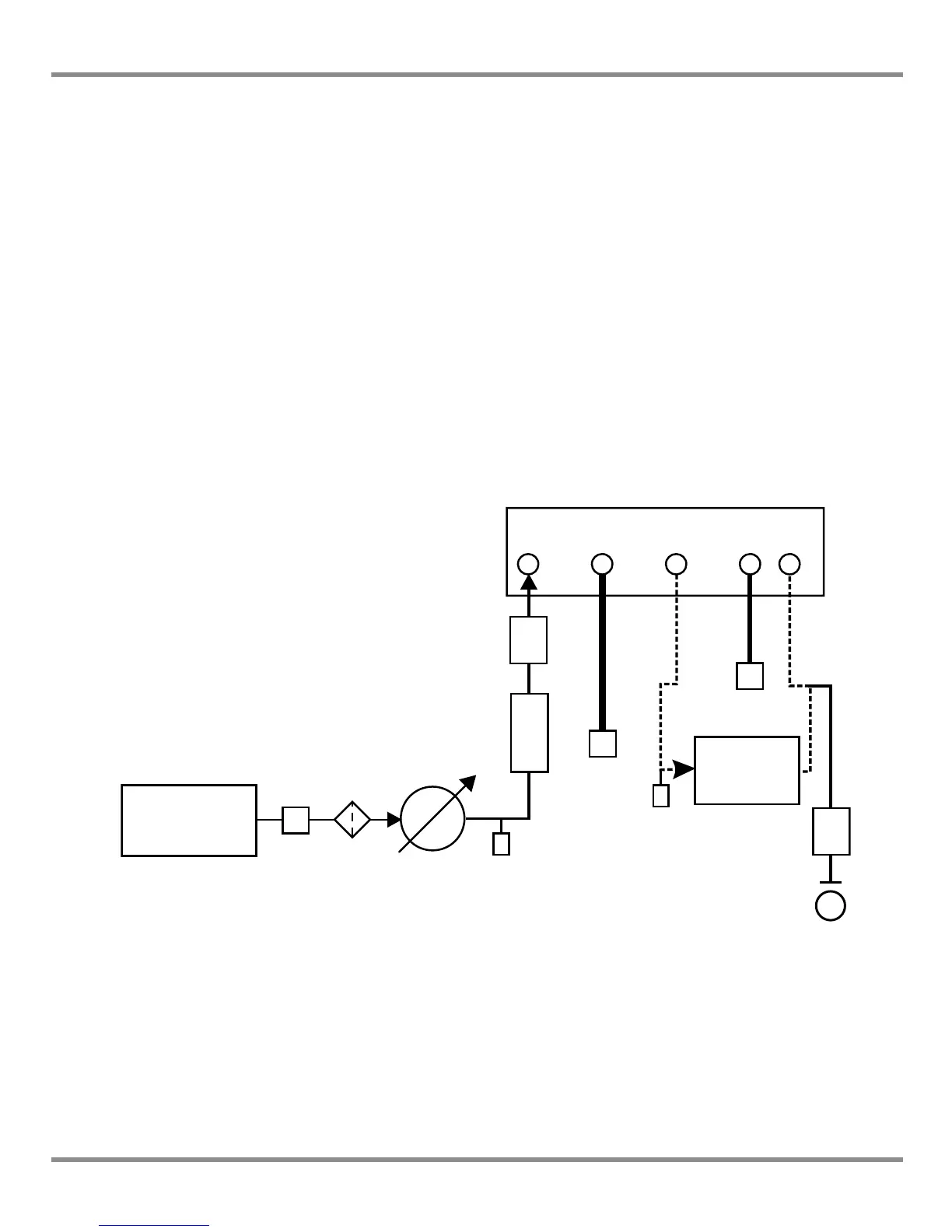

Pneumatic Connection Examples (Ref: Figures 2-3, 2-4 and 2-5)

The examples that follow show a single channel connection detail, using supply equipment

described above.

Figure 2-3, Pneumatic Connections without vacuum supply

1) Pressure source 2) Conditioner 3) Filter

4) Regulate to between 110% full-scale and MWP 5) Diffuser*

6) Unit under test 7) Optional reservoir † 8) Protection device

9) Optional differential connection 14) Manual external vent valves

a) Atmosphere

OUTPUT

1

2

3

4

5

6

7

+

5

9

a

-

SUPPLY

VENT REF

8

14

14

Loading...

Loading...