5 - Operation

57

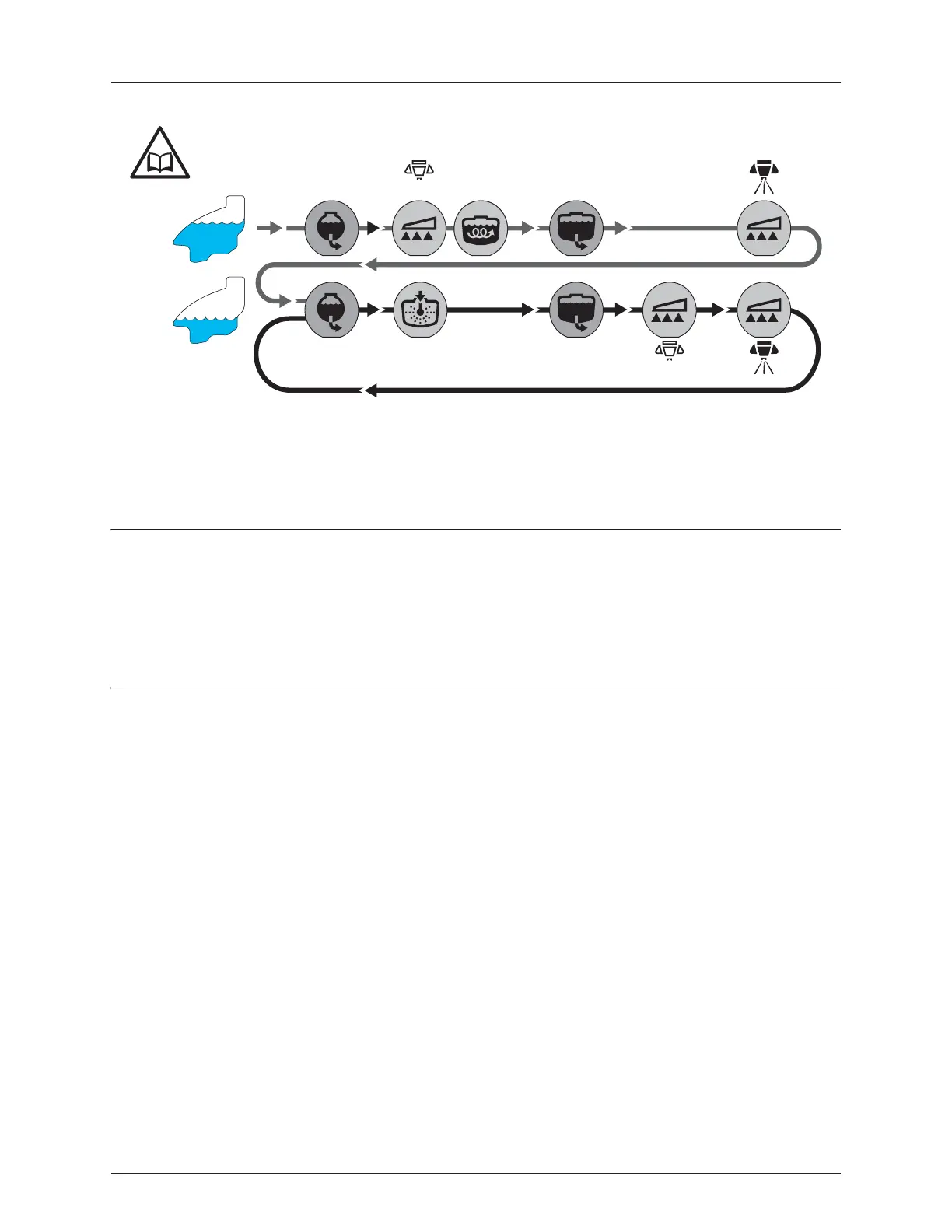

Quick reference - Cleaning

A. Full agitation.

B. Engage FlexCapacity pump. Spray until air comes out of nozzles.

C. Min. 45 seconds with nozzles OFF.

D. Spray until air comes out of nozzles.

Cleaning and maintenance of filters

Clean filters ensure:

• Sprayer components such as valves, diaphragms and operating unit are not hindered or damaged during operation.

• Nozzle blockages do not occur while spraying.

• Long life of the pump. A blocked suction filter will result in pump cavitation. The main filter protecting sprayer

components is the suction filter. Check it regularly.

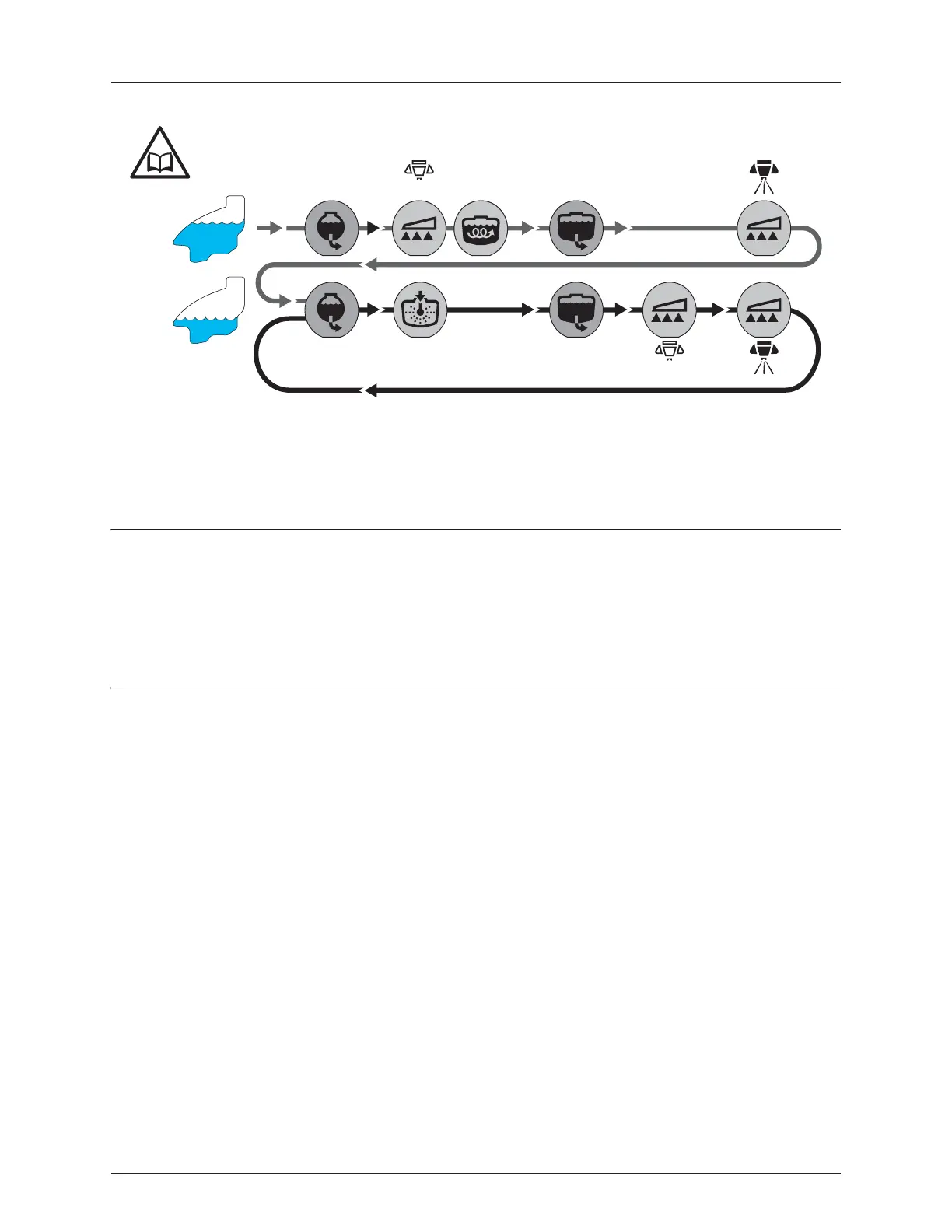

Use of rinsing tank and rinsing nozzles

The incorporated rinsing tank can be used for three different purposes:

A. Full internal rinsing (in-field before cleaning or when using same chemicals again soon).

B. External cleaning (can only be carried out on completion of “A”).

C. Rinsing spray circuit without diluting main tank content.

D. Full internal cleaning (before storage or when switching chemicals).

ATTENTION! The cleaning procedures stated requires the TurboFiller to be cleaned out beforehand (directly after the

last chemical filling). If the TurboFiller has not been cleaned, it must be cleaned before performing cleaning

procedures A, B, C or D - see “TurboFiller rinsing” on page 53.

÷

Note that cleaning the TurboFiller will use water from the rinsing tank, reducing the available quantity for cleaning

procedures A, B, C or D.

ATTENTION! Do NOT add any cleaning detergents into the rinsing tank. If cleaning agents are to be used, they should

be added the main tank.

A

1/31/3

4 x 1/64 x 1/6

B

C D

Loading...

Loading...