6 - Maintenance

70

Occasional maintenance

General info

The maintenance and replacement intervals for the following will depend very much on the conditions under which the

sprayer will be operated and are therefore impossible to specify.

Model 464 pump valves and diaphragms replacement

Diaphragm pump overhaul kit (valves, seals, diaphragms etc.) can be

ordered. Detect the pump model - kit can be ordered using correct

HARDI® part No.:

Model 464: part No. 75586000

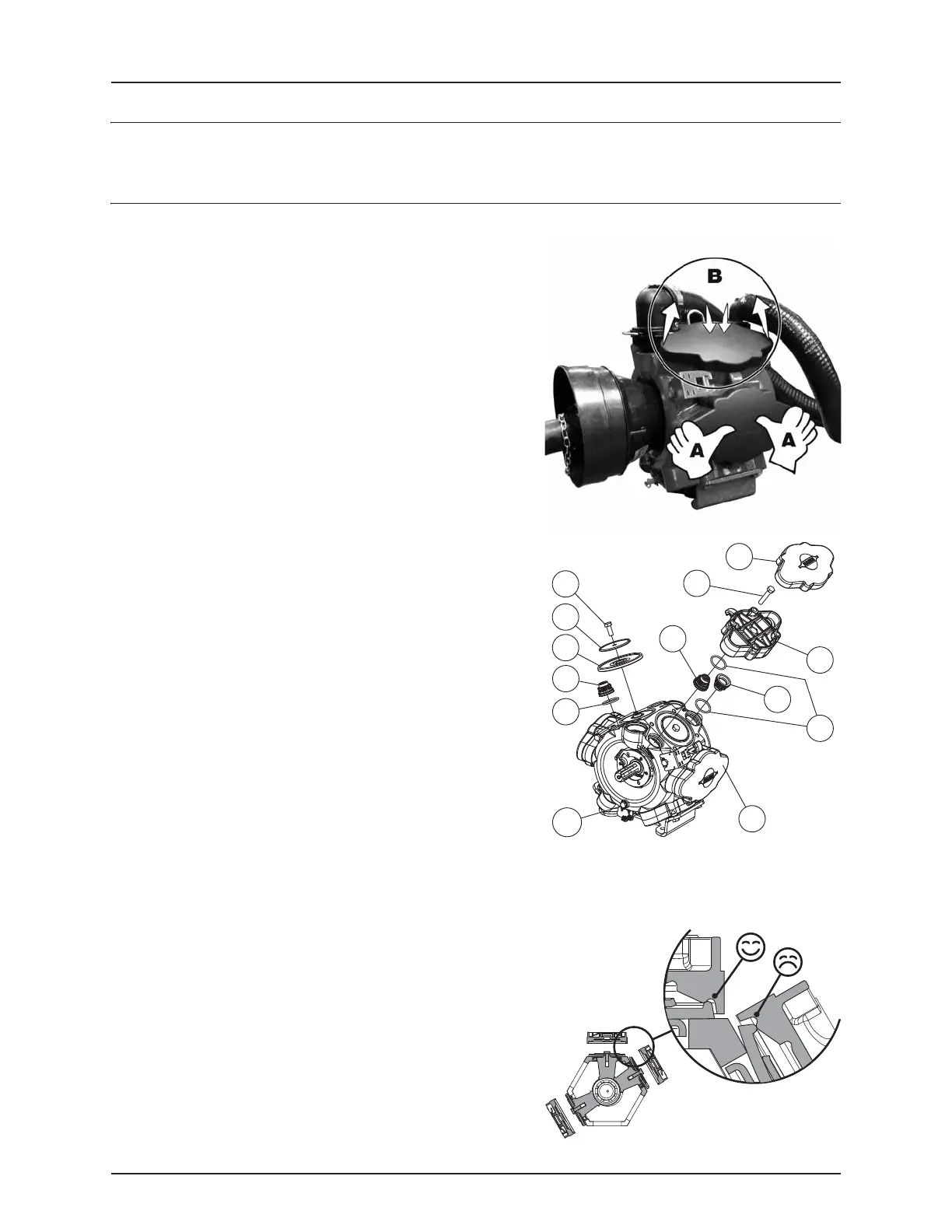

1. Lift off the plastic covers (C) with your hands (A) by pulling with the

finger tips while pushing with the thumbs in the center, as shown

in (B).

Valves

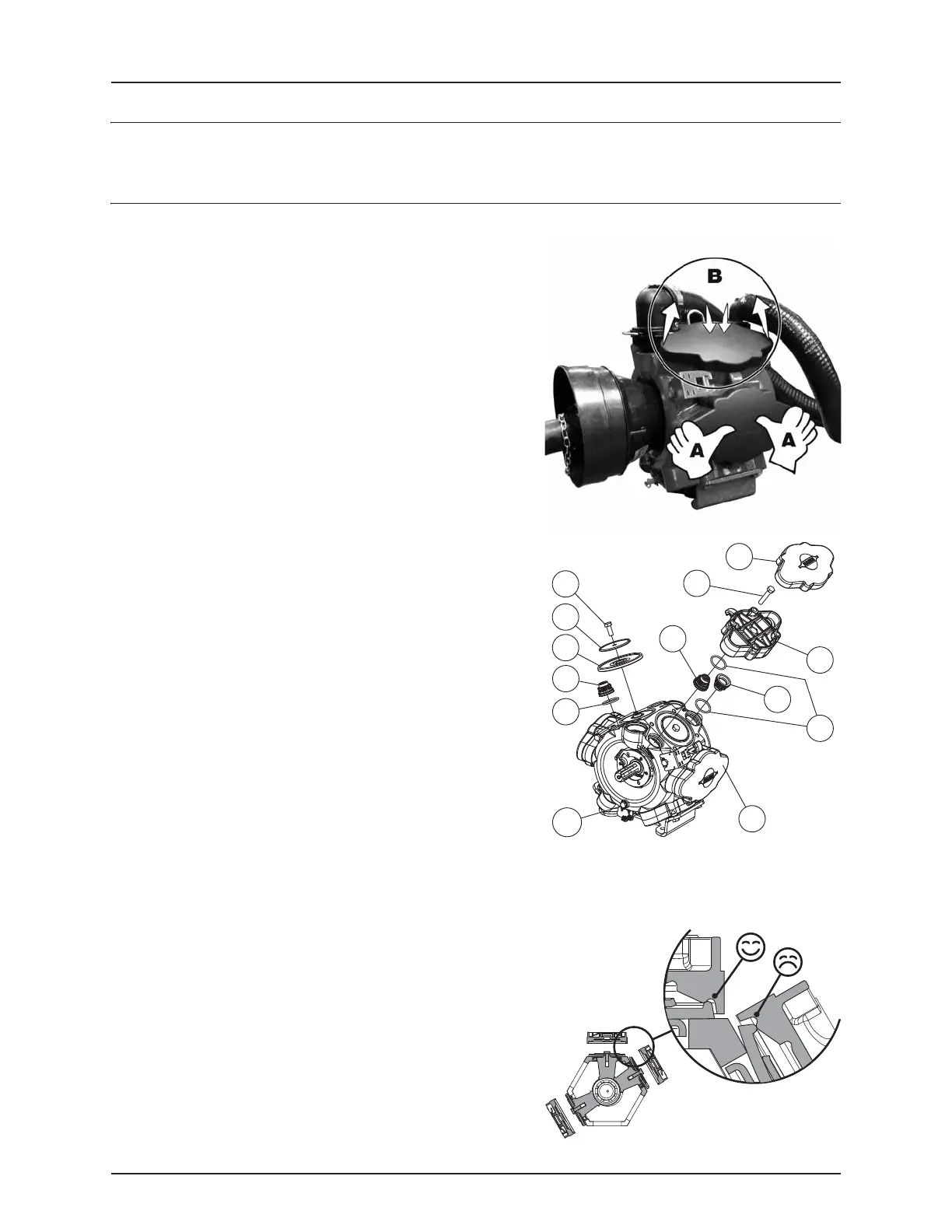

2. Loosen the 4 head bolts (1).

3. Remove the head (2).

4. Change the valves (3) - note their orientation so that they are

replaced correctly!

ATTENTION! It is recommended to use new gaskets (4) when

changing or checking valves.

Diaphragms

5. Loosen the diaphragm bolt (5).

6. Remove the diaphragm washer (6).

7. The diaphragm (7) may then be changed.

8. Check that the drain hole (8) at the bottom of the pump is not

blocked.

9. Apply a small amount of pump grease on the underside of the

diaphragms (between diaphragm and connecting rod washer).

10. Reassemble the pump with the following torque setting:

• Diaphragm head bolts (1): 67 Ft/lb (90 Nm)

• Diaphragm bolt (5): 67 Ft/lb (90 Nm)

• Refit the plastic covers (C).

÷

NOTE! The diaphragm bolt on 1000 r.p.m. pumps must be

secured with a locking compound such as Loctite® 262

(HARDI® Part No.: 28045503).

ATTENTION! Before tightening the 4 bolts for the head (2), the

diaphragm must be positioned between the center and top to

ensure correct sealing between the diaphragm pump housing

and diaphragm cover. Turn the crank shaft if necessary.

C

C

1

2

3

3

3

4

4

5

6

7

8

Loading...

Loading...