6 - Maintenance

71

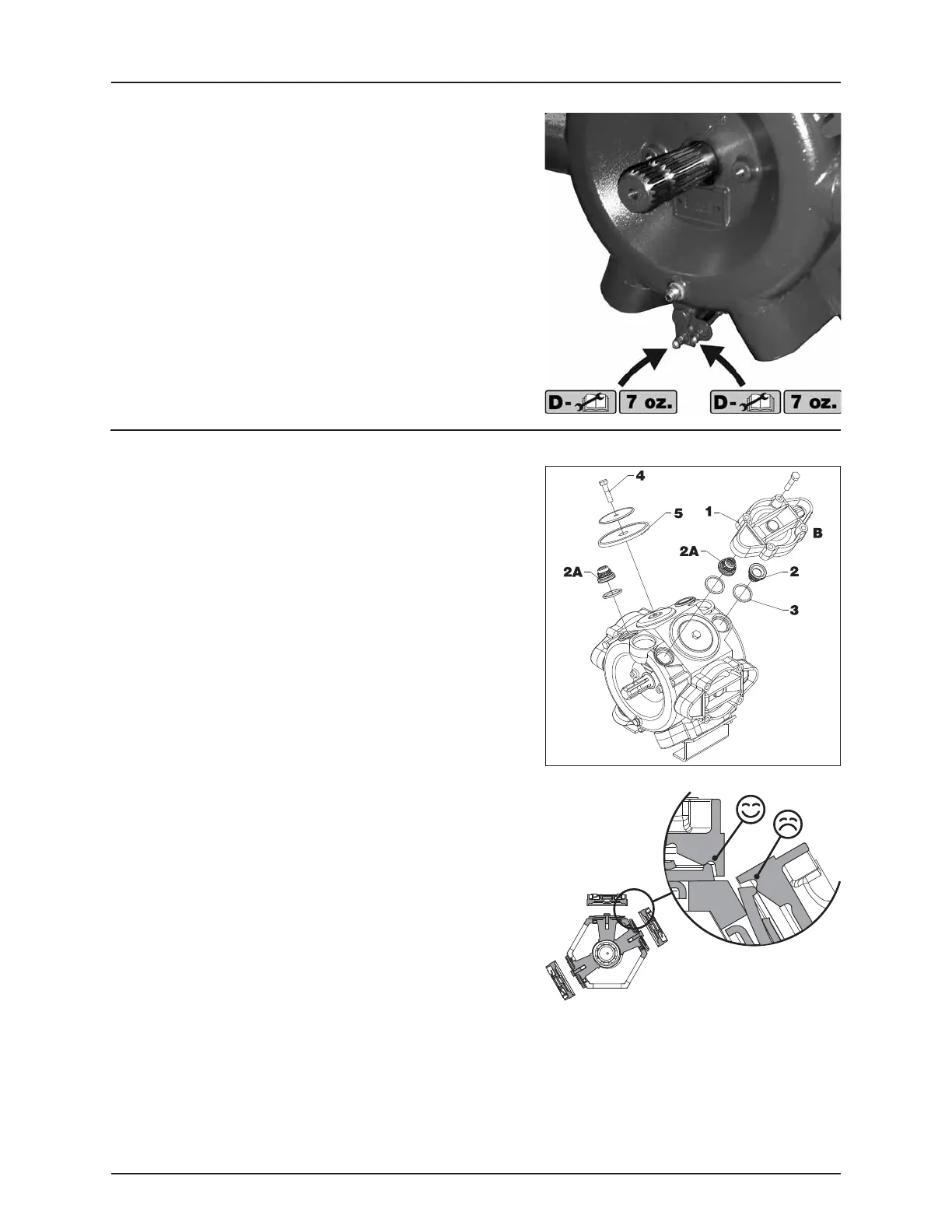

Re-lubrication after assembly

After disassembling the pump (diaphragm replacement, etc.), the pump

MUST be lubricated with 7 oz. (200 grams) grease into each lubrication

point.

ATTENTION! In order to avoid excessive wear, it is important to

use a recommended lubricant (i.e. HARDI® part no. 28164600).

See “Recommended lubricants” on page 63.

Model 463 pump valves and diaphragms replacement

Diaphragm pump overhaul kit (valves, seals, diaphragms etc.) can be

ordered. Detect the pump model - kit can be ordered using correct

HARDI® part No.:

Model 463: part No. 75073900

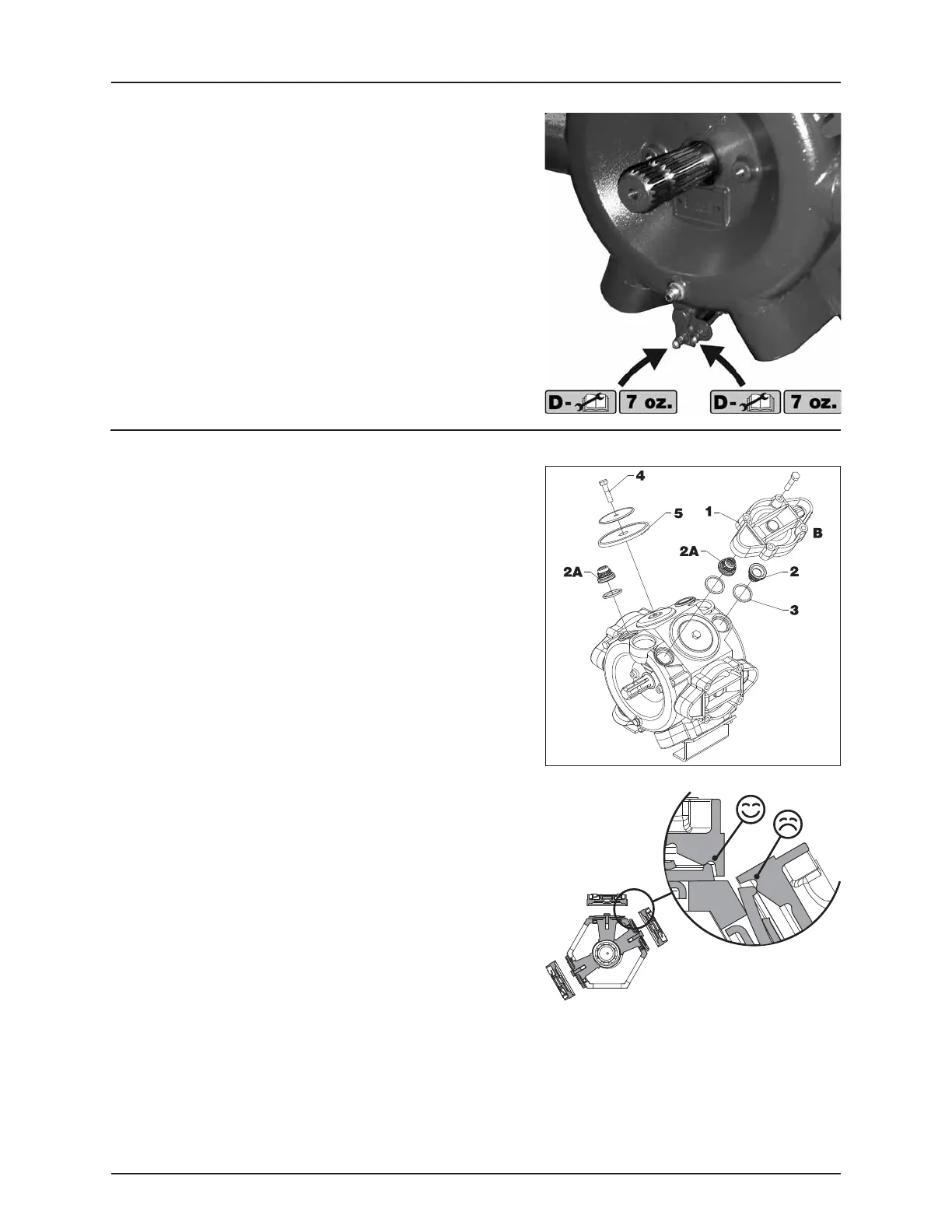

Valves

Remove valve cover (1) before changing the valves (2) - note their

orientation so they are replaced correctly!

AT TENTION! A special valve with white flap (2A) is used at the two

upper side inlets. It has to be placed in the valve openings as

shown. All others are the type with black flap. It is recommended

to use new gaskets (3) when changing or checking the valves.

Diaphragms

Remove the diaphragm cover (4). The diaphragm (5) may then be

changed. If fluids have reached the crankcase, re-grease the pump

thoroughly. Also check that the drain hole at the bottom of the pump is

not blocked. Reassemble with the following torque setting.

Reassemble pump model 463 with the following torque setting.

Diaphragm cover: 67 Ft/lb (90 Nm)

Diaphragm bolt: 67 Ft/lb (90 Nm)

ATTENTION! Before tightening the 4 bolts for the diaphragm cover (B) the diaphragm must be positioned between

center and top to ensure correct sealing between diaphragm pump housing and diaphragm cover. Turn crank shaft

if necessary.

Loading...

Loading...