63

6 - Maintenance

Lubrication

General info

Always store lubricants clean, dry and cool - preferably at a constant temperature - to avoid contamination from dirt and

condensed water. Keep oil filling jugs, hoppers and grease guns clean, and clean the lubricating points thoroughly before

lubricating. Avoid skin contact with oil products for longer periods.

Always follow the quantity recommendations. If no quantity is recommended, feed lubricator till new grease becomes

visible.

Pictograms in lubrication & oiling plans designate the following:

1. Lubricant to be used (see “Recommended lubricants”).

2. Recommended intervals (hours).

ATTENTION! If the sprayer is cleaned with a high pressure cleaner,

lubrication of the entire machine is recommended.

Recommended lubricants

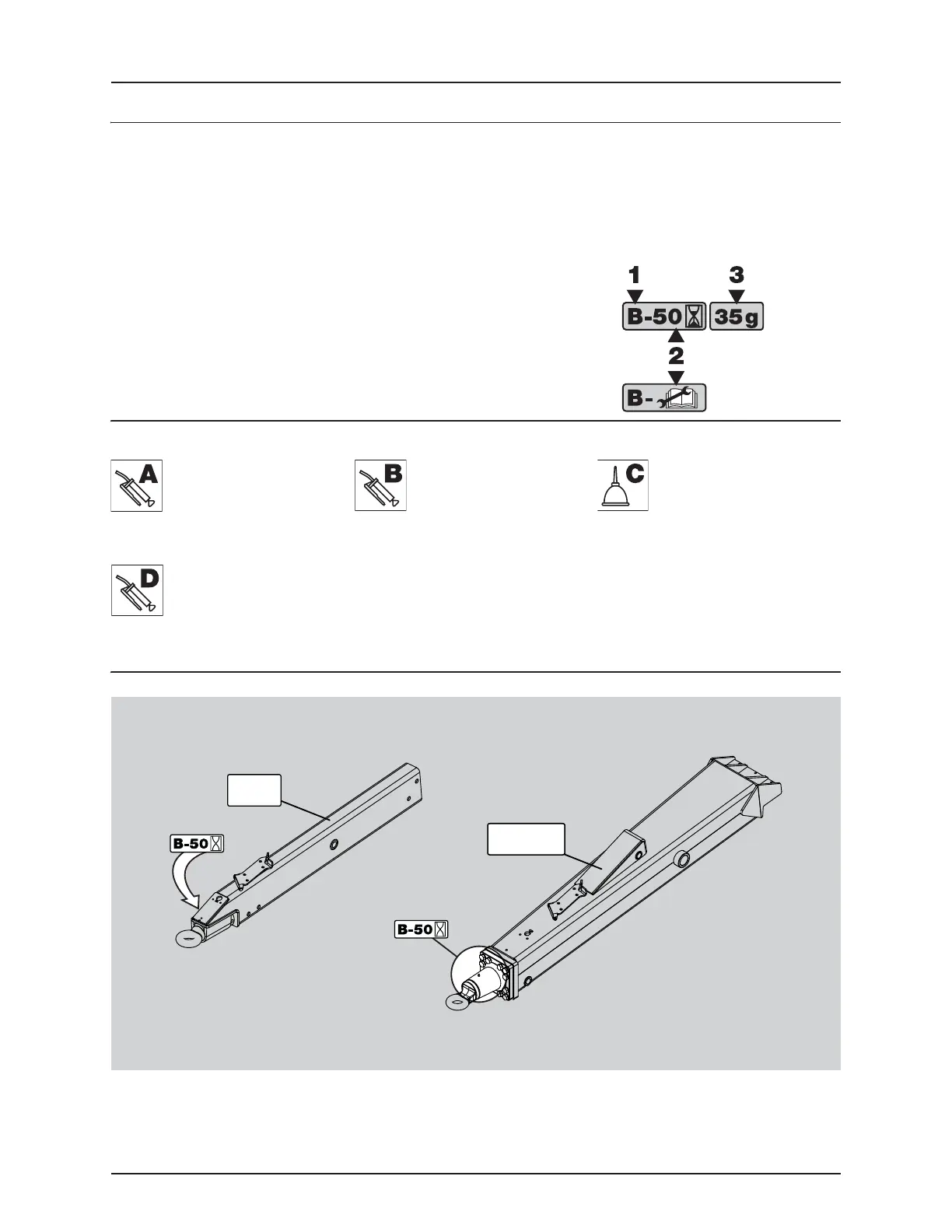

Drawbar lubrication

BALL BEARINGS:

Universal Lithium grease, NLGI No. 2

SHELL RETINAX EP2

CASTROL LMX GREASE

SLIDE BEARINGS:

Lithium grease with

Molybdenumdisulphide or graphite

SHELL RETINAX HDM2

CASTROL MOLYMAX

OIL LUB. POINTS:

TOTAL Transmission TM

SAE 80W/90

Castrol EPX 80W/90

SHELL Spirax 80W/90

Mobil Mobilube 80W/90

PUMPS:

Complex Lithium grease, NLGI No. 1

Viscosity @104°F (40° C) > 460 cSt

SHELL Gadus S3 V550L 1

Mobilgrease XHP 462

TOTAL Multis Complex SHD 460

Models

5500/7000

Model

4500

Loading...

Loading...