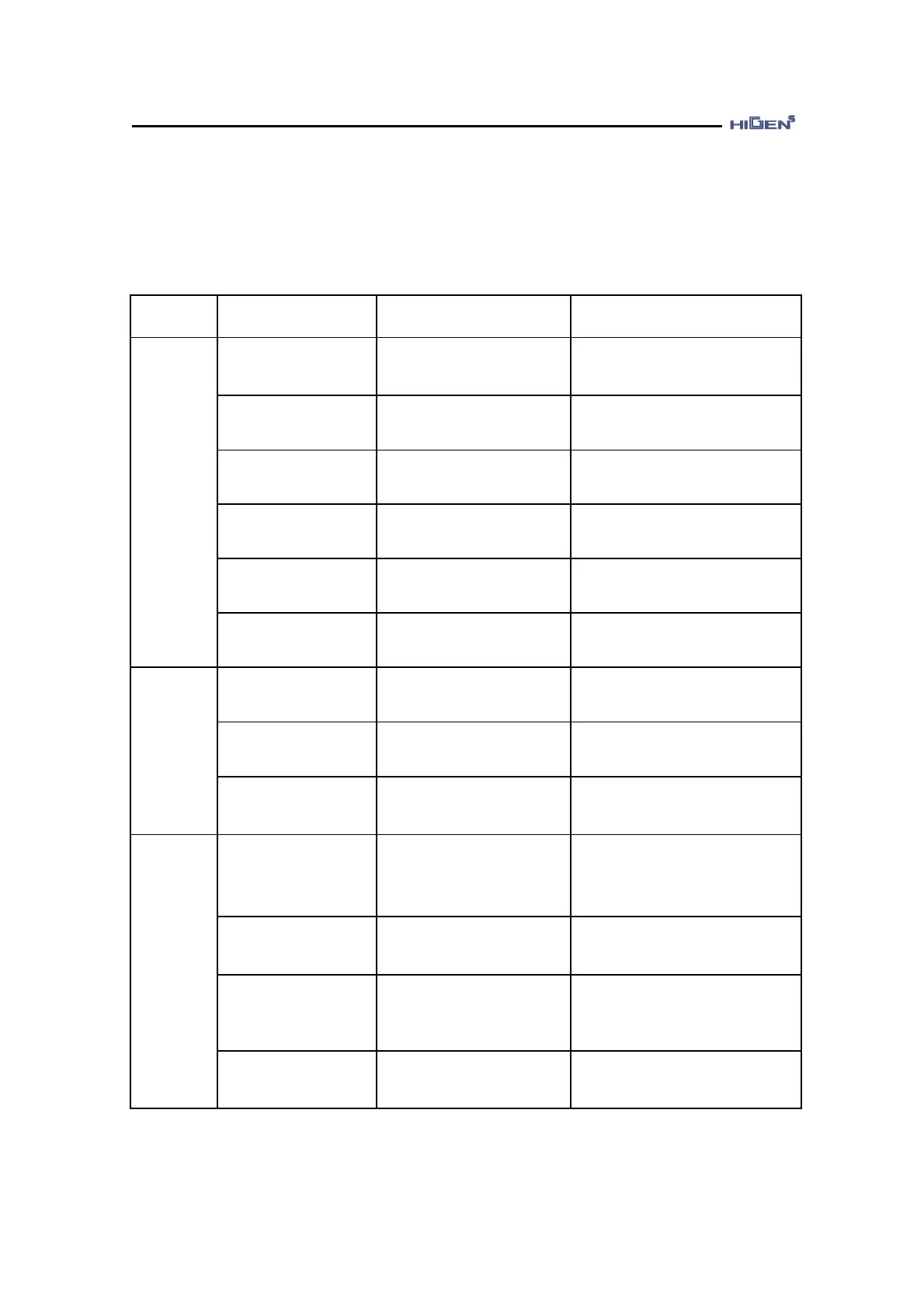

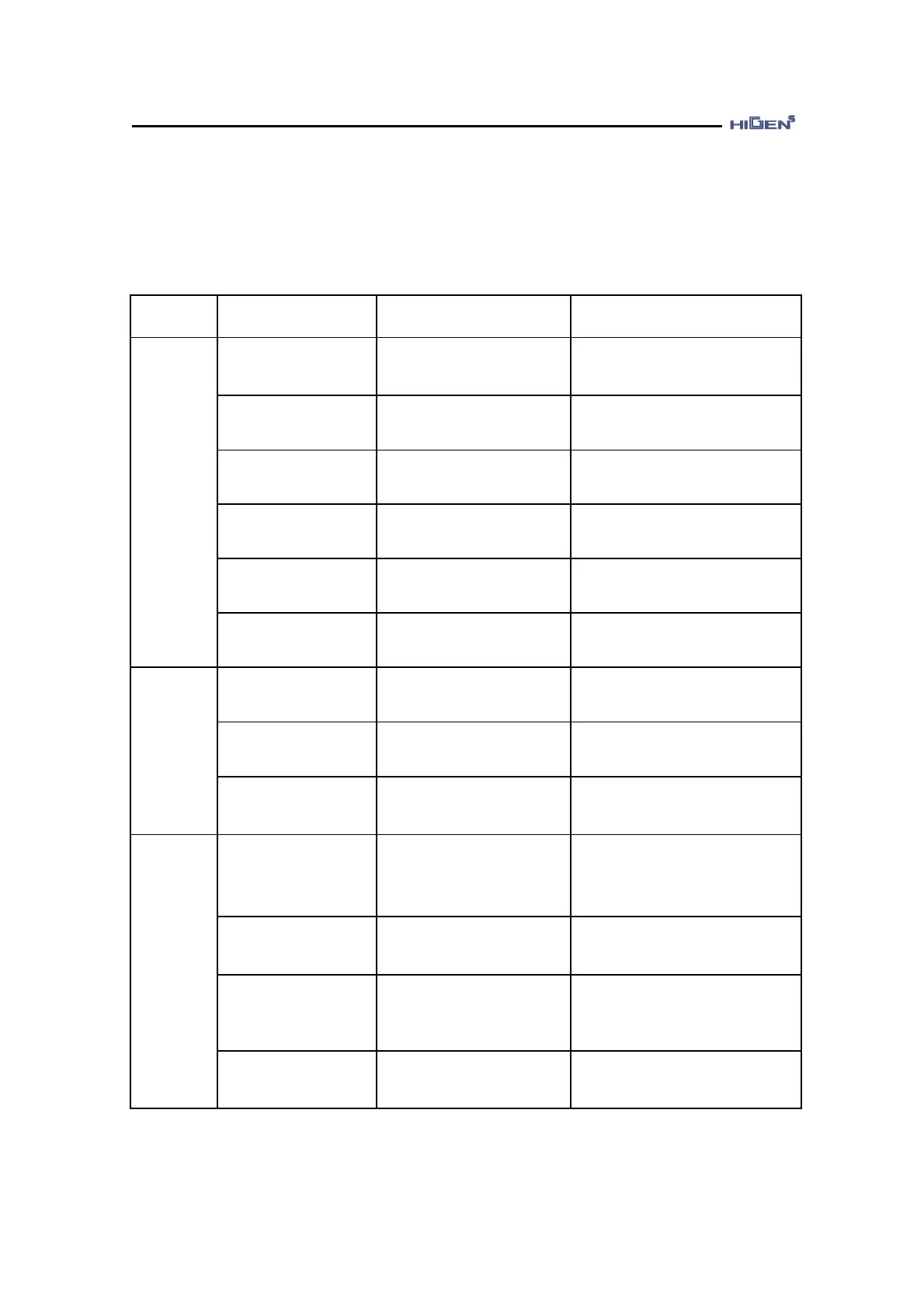

6. Troubleshooting and check

6-1

6.1. Troubleshooting

6.1.1. Servo motor

Check the parameter of

motor, encoder, encoder

type, control mode etc.

Reset parameter.

(Refer to Chapter 3)

Check the revolution

condition of the machine.

Readjust the machine device.

Measure the motor lead

terminal with a tester.

For normal voltage, replace the

motor.

Check the connection part

with drive.

External mis-wiring

Cable disconnection

Check motor and encoder

wiring.

Rework on the wiring.

Replace the cable.

Check the output wave

shape.

Replace the encoder.

(Request for repair)

Motor

revolution

is unstable

Wiring connection

defectiveness

Check the connection of

the motor lead terminal.

Check the drive input

voltage.

Check the machine

condition.

Remove any particle on the

revolution part and supply

lubricant (or grease)

Check the surrounding

temperature of the motor

installation part.

(40 or below)

Reduce ambient temperature to

40 max.

Contamination on

motor surface

Check whether there are

any alien particles on the

motor surface.

Check the load rate of the

drive. Check the

acceleration/deceleration

frequency.

Reduce load. Increase

acceleration/deceleration time.

Low magnetic power

of magnet

Check the comparator

voltage and voltage wave

shape.

Loading...

Loading...