6. Troubleshooting and check

6-2

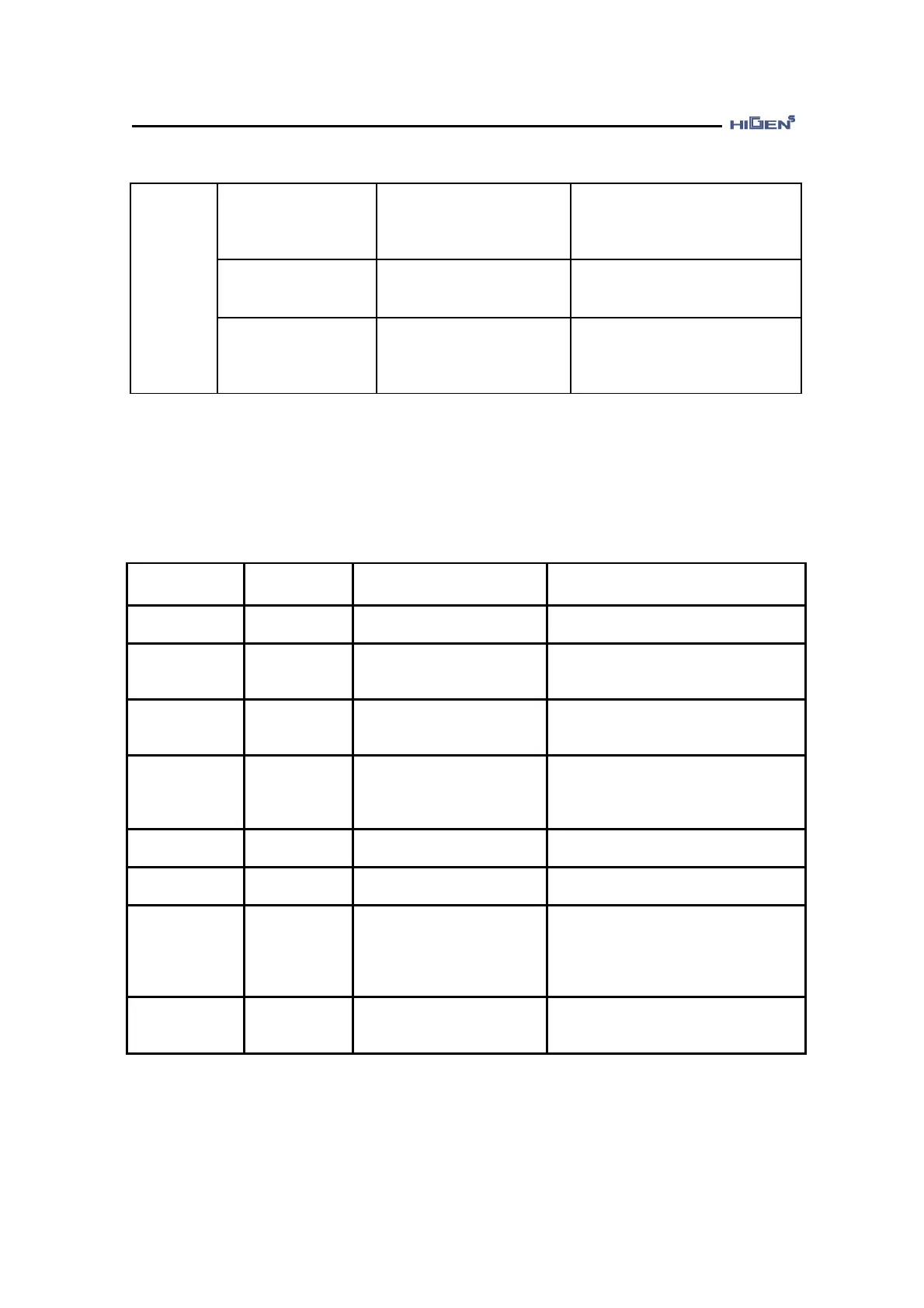

Abnormal

noise is

generated.

Check the screw condition

of the coupling and copper

core of the connection

part etc.

Check the bearing

vibration and abnormal

noise.

Parameter mis-

setting(Motor/encoder

ID, inertia ratio, gain,

TC)

Check the control

parameter.

Refer to parameter setting

method in chapter 3.

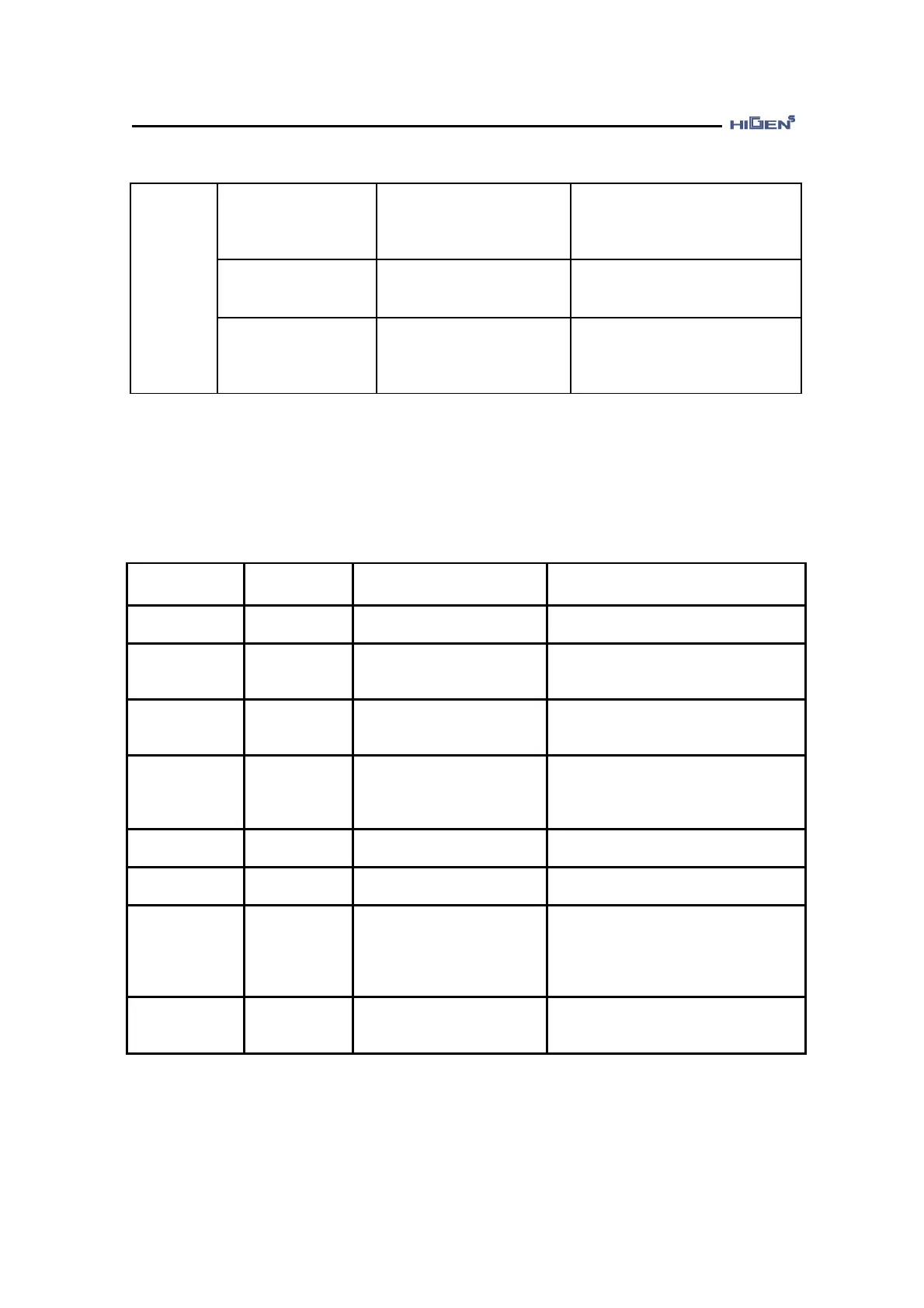

6.1.2. Servo drive

When an alarm occurs in servo drive and error signal output contact point (ALARM) goes OFF

and the motor is stopped by dynamic brake.

Turn external ESTOP

contact point input OFF.

Check external DC 24V power.

Check ESTOP contact point ON

status

Servo drive output terminal

(U, V, W) short circuit,

output over-current

Check output terminal wiring, re-

operate after resetting, replace drive

when O.C continues

Input over-voltage

(280V or above)

Regenerated resistance

burnt, Overload GD

2

Use input voltage of 230V or below

Replace brake resistance, increase

acceleration/deceleration time,

replace servo drive

Mechanical overload

Motor mis-wiring

Check load condition, check motor

and encoder wiring

Main power blocked when

SERVO is ON

Check 3 phase main power (R, S, T)

input condition

Mis-wiring of

motor and

encoder

Motor and encoder related

set value error, motor and

encoder mis-wiring,

encoder defect,

mechanical overload

Check motor, encoder, wiring and

set value, remove overload

Over-gain, parameter set

value error,

over gravity load

Adjust gain

Check parameter (P03-15, P03-16)

Remove over gravity load

Loading...

Loading...