MAINTENANCE

7-9

PERIODIC REPLACEMENT OF PARTS

To ensure safe operation, be sure to conduct periodic inspec-

tion of the machine. In addition, the parts listed below, if defec-

tive, may pose serious safety/fire hazards. It is very difficult to

gauge the extent of deterioration, fatigue, or weakening of the

parts listed below simply by visual inspection alone. For this

reason, replace these parts at the intervals shown in the table

below. However, if any of these parts are found to be defective,

replace before starting operation, regardless of the interval.

Also, when replacing hoses, check the clamps for deformation,

cracks, or other deterioration, and replace as necessary.

Be sure to perform periodic inspection of all hoses, as shown

below, and replace or retighten any defective parts found, as

necessary.

Consult your authorized dealer for correct replacement.

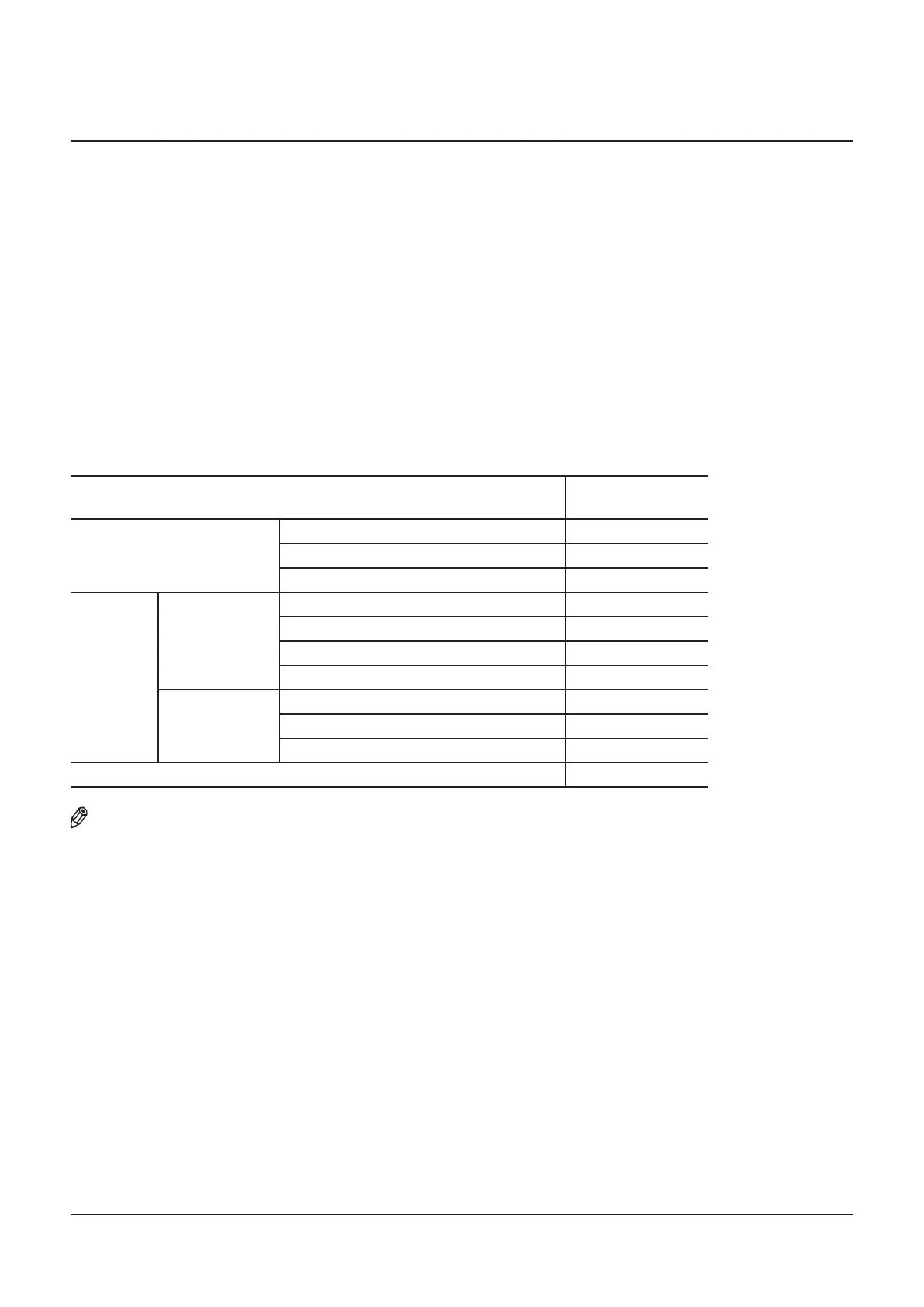

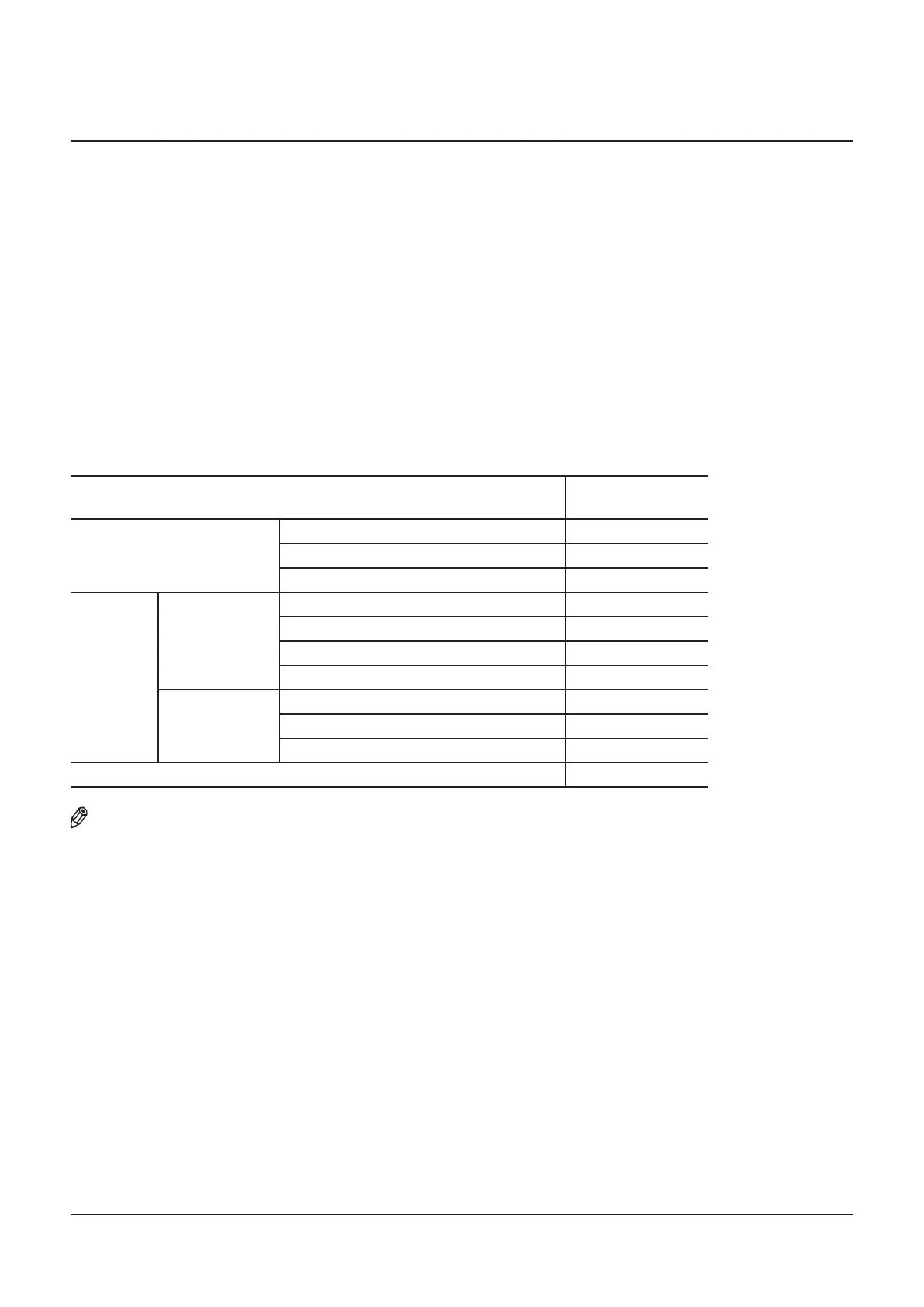

Periodic Replacement Parts

Replacement

Intervals

Engine

Fuel hose (Fuel tank to Supply pump) Every 2 years

Oil filter hose (Engine to oil filter) Every 2 years

Heater hose (Heater to engine) Every 2 years

Hydraulic

System

Base Machine

Pump suction hose Every 2 years

Pump delivery hose Every 2 years

Swing hose Every 2 years

Travel high pressure hose Every 2 years

Front

Attachment

Boom cylinder line hose Every 2 years

Arm cylinder line hose Every 2 years

Bucket cylinder line hose Every 2 years

Seat belt Every 3 years

NOTE: Be sure to replace seals, such as O-rings and

gaskets, when replacing hoses.

Loading...

Loading...