9--4

109

Use and maintenance manual S20DSP

Lubricant/coolant fluid

The lubricant/coolant fluid must ensure so that neither the saw teeth nor the work

piece material in the cutting zone overheat. Furthermore, there must be a

sufficient quantity and pressure of lubricant/coolant to remove swarf from the

cutting zone. The lubricant/coolant fluid must be of the highest quality in order to

prevent tooth abrasion and welding of swarf to the teeth themselves (seizing).

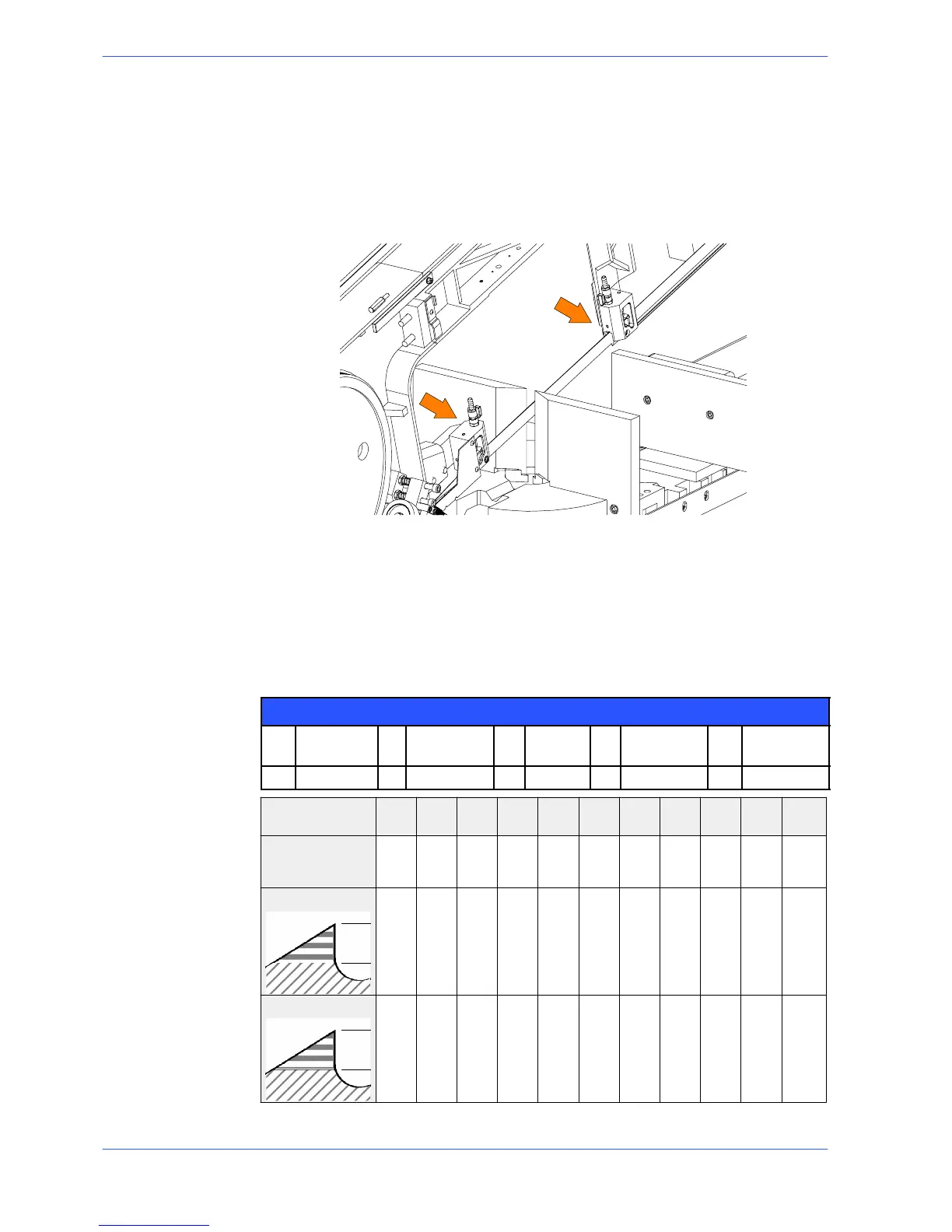

Blade structure

The most commonly used blades are the bimetal types, i.e. manufactured with a

silicon steel body and having a high fatigue strength, and super high---speed steel

teeth; the two parts are welded by electronic or laser---welding.

Standardised teeth types are termed M2 and M42; the difference being that M42

teeth are harder due to the addition of cobalt to the steel used to make the teeth.

Key

Mo Molyb-

denum

Ni Nickel Si Si licon V Va n a d i um W Tun gst en

Al Aluminium C Carbon Co Cobalt Cr Chromium Mn Manganese

HSS M2

HSS M42

C Mn Si W Mo V Ni Co Al HRCCr

0,47 0,75 0,22 1,00 1,00 0,12 0,52 0,08 45--50

0,85 0,25 0,30 4,15 6,37 5,00 1,92 64--66

1,07 0,25 0,20 3,75 1,50 9,50 1,15 8,00 67 --69

HRC 67--68

HRC 45--50

HRC 65--66

HRC 45--50

TYPE OF

BLADE

The numbers in the columns indicate the % content of the element in the steel.N.B.

Loading...

Loading...