4--5

25

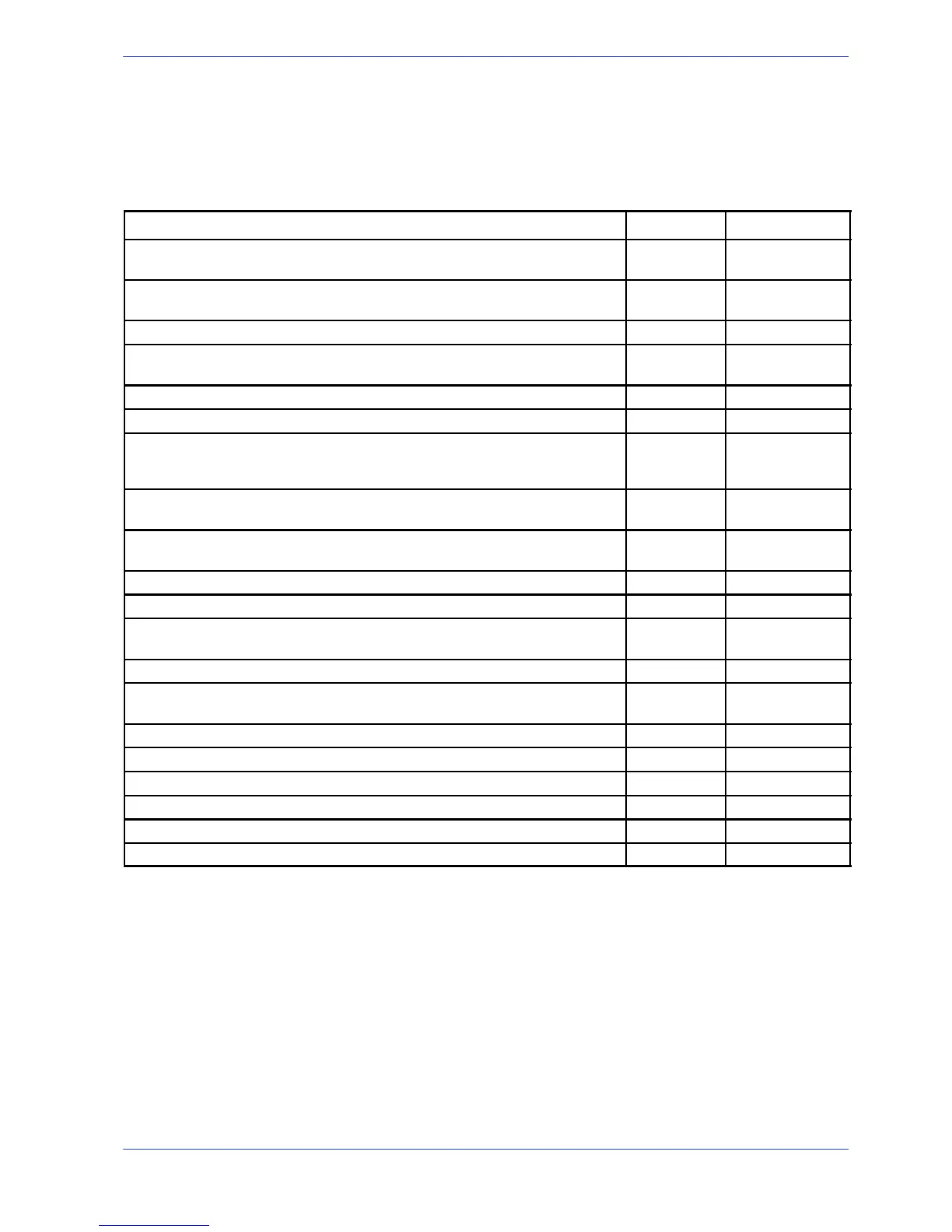

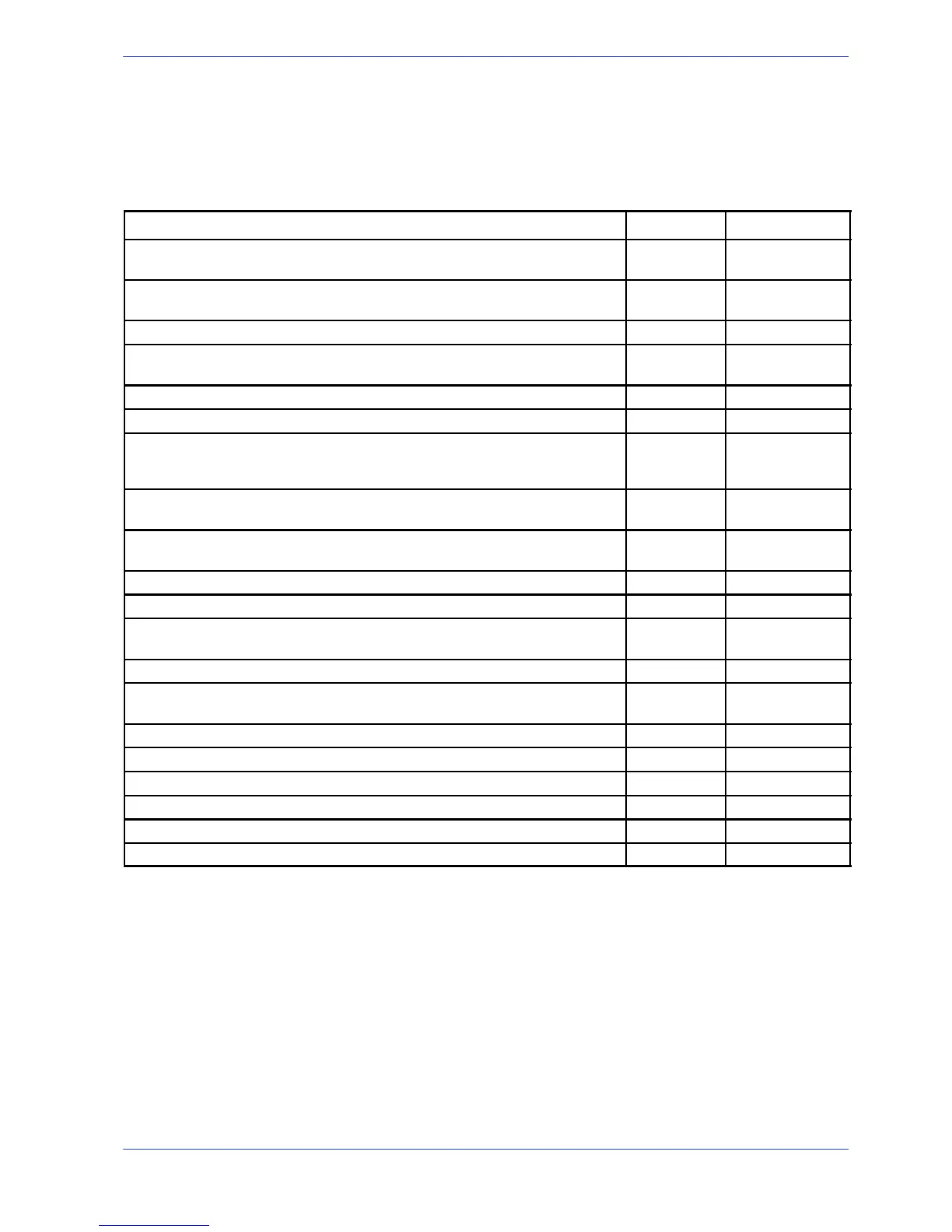

Machine installation

Check list

Before starting installation, check that all the accessories, whether standard or

optional, supplied with the machine are present.

CHARACTERISTIC S

STANDARD OPTIONAL

Base with large swarf collection drawer, removable coolant tank and electro-

pump for band saw lubrication/cooling

n

Bar support sliding on straight ball guides, located to the left of the cutting

table

n

Mechanical variator of blade rotation from 20 to 100m/min n

Small head mobile blade---guide running on the linear guides and slides with

re---circulation of pre---loaded spheres

n

Blade 4500 x 27 x 0,9 mm n

Recordable stroke to perform cuts of the same size n

Rotating head on a rotating surface with ball bearings and recordable strokes

allow the stopping and the blocking in correspondence of the 0˚,45˚,60˚

right and 45˚,60˚ left angles

n

Electronic transducer of the stretching of the band with display on the con-

sole

n

Blade cleaning device with rotating brushes with movement transmitted from

the pulley engine

n

Designed for transpallet handling systems n

Mobile console to ope rate while maintaining visual control n

Manual vice with screws with rapid nearing and transfer on the linear guides

a n d s l i d e s w i t h r e --- c i r c u l a t i o n o f p r e --- l o a d e d s p h e r e s

n

Motorchipdischargerunit n

Steel blade guide head with adjustable hard metal blocks which open to facili-

tate blade replacement

n

Work table spray gun n

Accessory kit n

Vertical roller table pair n

Feed roller table K250 (1500 x N) n

Discharge roller table K250 (1500 x N) n

Cutting oil 5 lt n

*ACCESSORIES AVAILABLE ON REQUEST

The bag of accessories is enclosed in the machine before being packed and

contains:

H hex wrenches 3/4/5/6/10 mm;

H pipe wrench 10 mm;

H 36mm wrench;

H use and Maintenance manual, including order form for parts in relevant user lan-

guage.

Loading...

Loading...