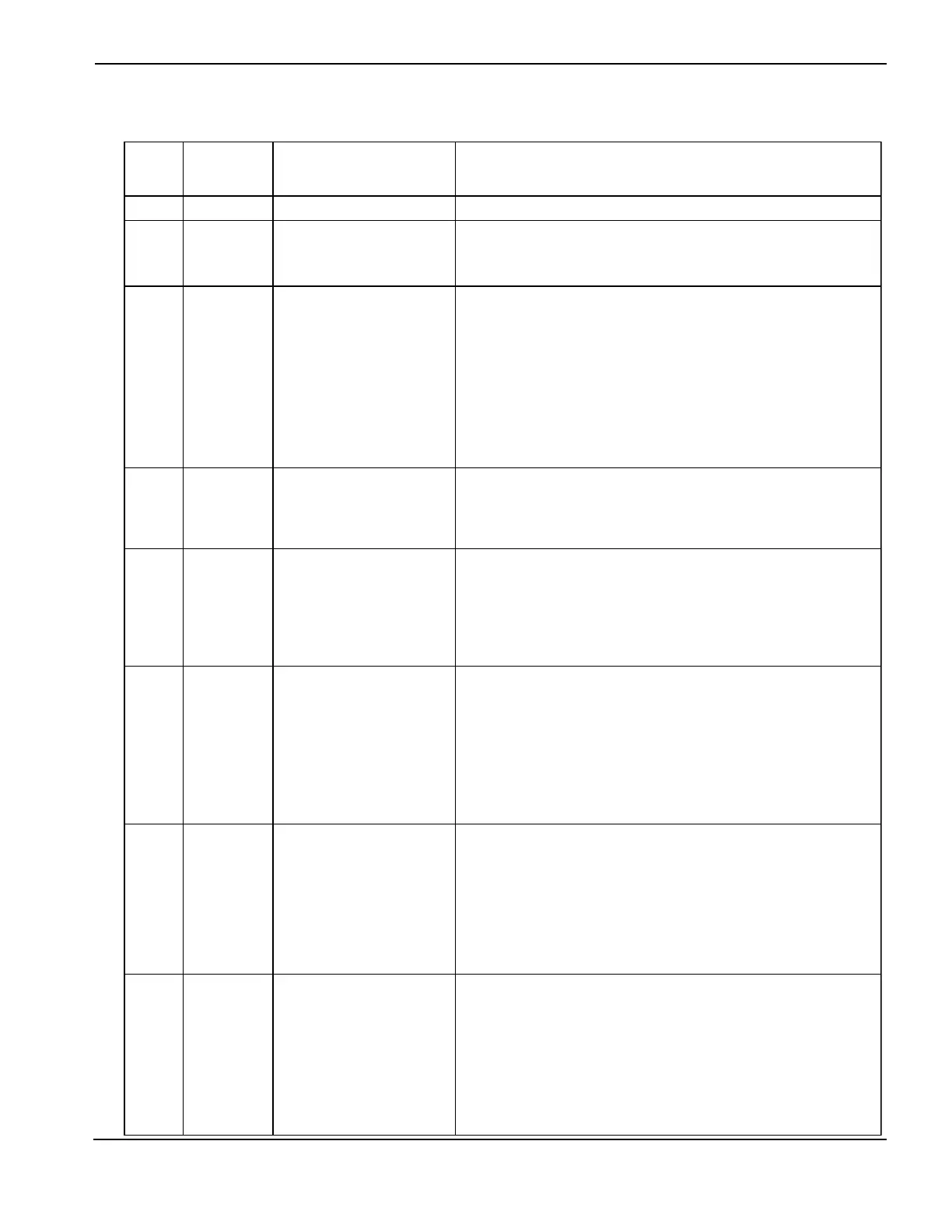

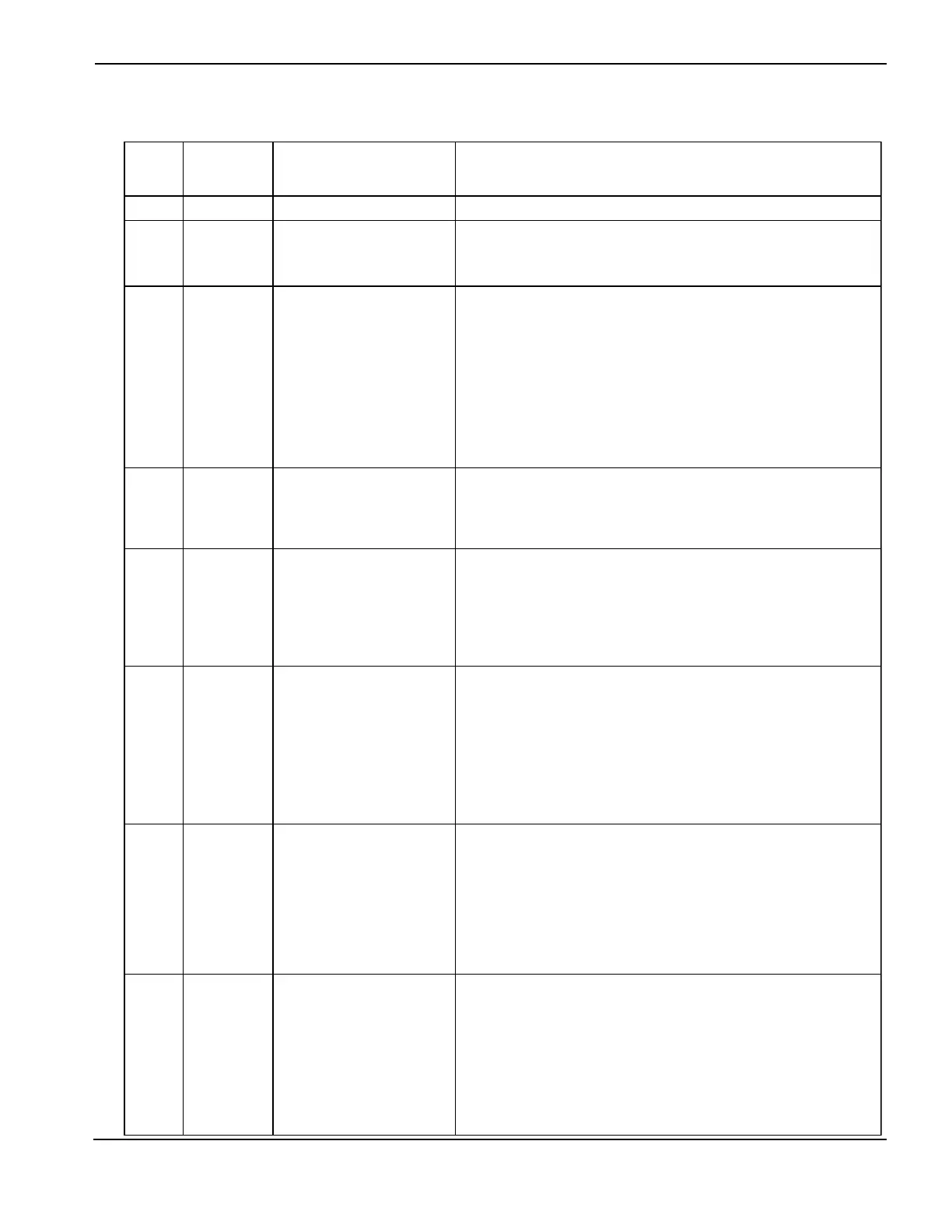

Error code troubleshooting (1 of 6)

Error

code

No.

Name Description Corrective action

0 No error System is ready to run None needed

1. Verify that coolant filters are in good condition.

2. Verify that there are no restrictions in the coolant system.

1. Verify that the consumable parts are in good condition.

2. Verify proper pre-flow and cut-flow settings.

3. Perform leak test.

4. Verify spark across spark gap.

5. Inspect CON1 and pilot arc relay for excessive wear.

6. Perform gas flow test (see

Maintenance

section).

7. Perform torch lead test (see

Maintenance

section).

8. Perform start circuit test (see

Maintenance

section).

9. Perform chopper test (see

Maintenance

section).

1. Verify proper pierce height.

2. Verify proper pre-flow and cut-flow settings.

3. Inspect work lead for damage or loose connections.

4. Perform current test (see

Maintenance

section).

1. Verify that the consumable parts are in good condition.

2. Verify proper cut-flow gas settings.

3. Verify pierce delay time.

4. Verify arc did not lose contact with plate while cutting (hole

cutting, scrap cutting, etc).

5. Perform chopper test (see

Maintenance

section).

1. Verify that the consumable parts are in good condition.

2. Verify proper cut-flow gas settings.

3. Verify pierce delay time.

4. Verify arc did not loose contact with plate while cutting (hole

cutting, scrap cutting, etc).

5. Inspect work lead for damage or loose connections.

6. Try connecting work lead directly to the plate.

7. Perform chopper test (see

Maintenance

section).

1. Verify phase-to-phase voltage to power supply.

2. Disconnect power to power supply, remove cover on

contactor and inspect contacts for excessive wear.

3. Inspect power cord, contactor, and input to chopper for loose

connections.

4. Inspect phase loss fuses on Power Distribution board.

Replace board if fuses are blown.

5. Perform phase loss test (see

Maintenance

section).

1. If a mechanical relay is being used to provide the HPR with a

start signal, this relay is either bouncing when activated or the

contacts are faulty. Replace the relay.

2. Inspect interface cable for damage; faulty crimps, or poor

electrical connections.

3. If interface cable is good and a relay is not driving the start

input, the CNC is dropping the start signal before a steady state

arc has been established.

18

Pump over

pressure

Pump output has

exceeded 13.79 bar (200

psi).

20 No pilot arc

No current detected from

chopper at ignition and

before 1-sec timeout.

21

No arc

transfer

No current detected on

work lead 500 milli-

seconds after pilot arc

current was established.

24 Lost current

Lost current from chopper

after transfer.

31 Start lost

Start signal was received

and then lost before an arc

was established.

26 Lost transfer

After transfer lost the

transfer signal.

27 Lost phase

Phase imbalance to

chopper after contactor

engaged or while cutting.

MAINTENANCE

HPR130 Manual Gas Instruction Manual 5-7

5

Loading...

Loading...