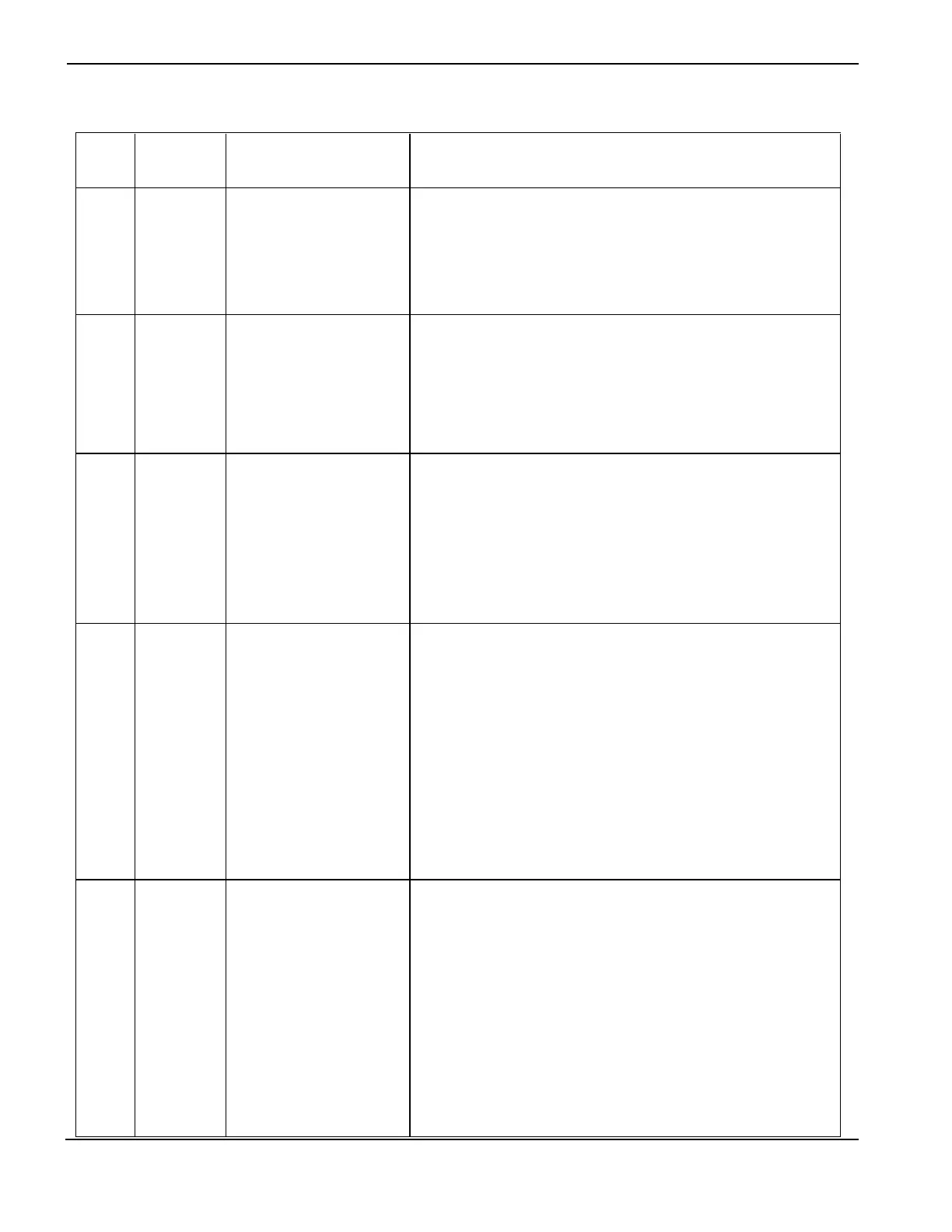

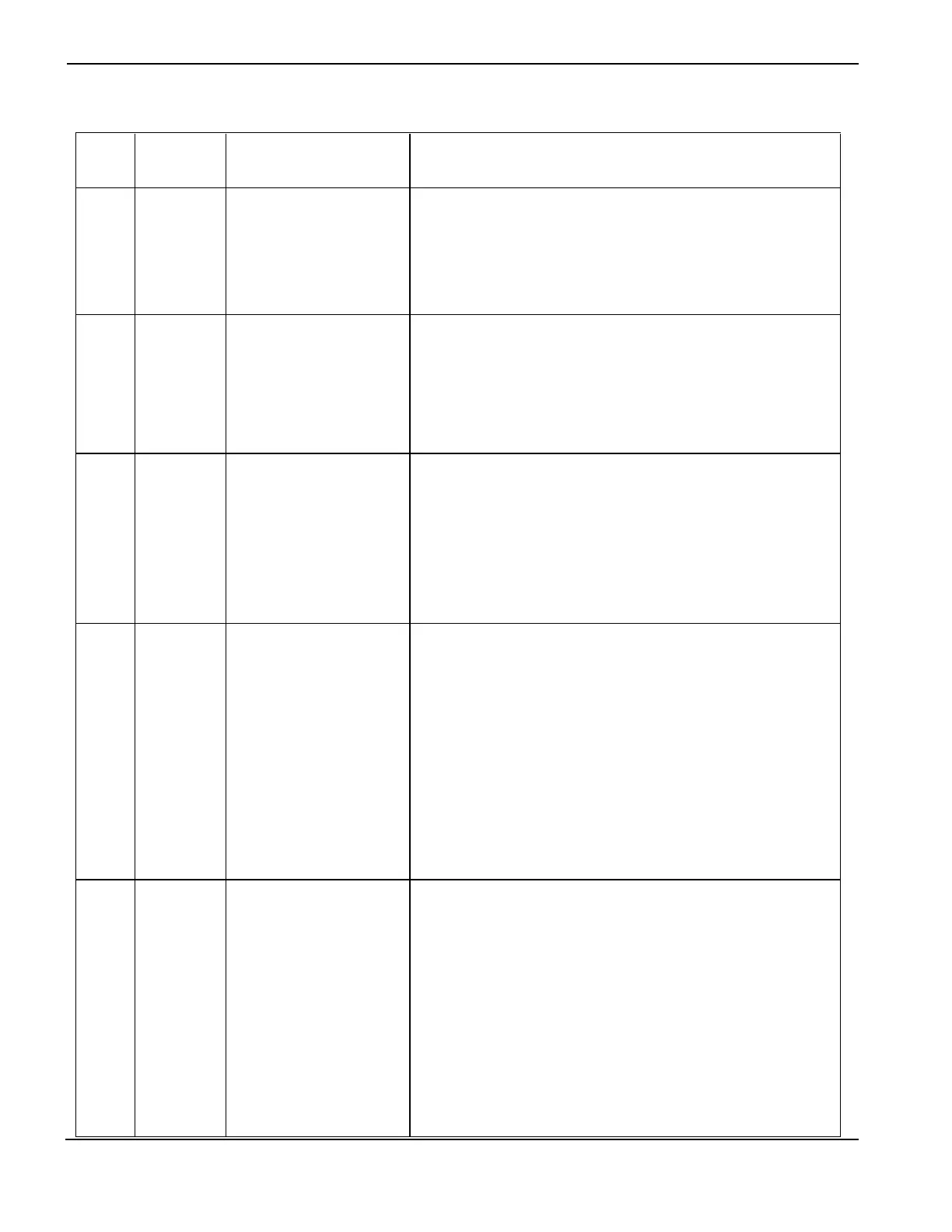

MAINTENANCE

5-8 HPR130 Manual Gas Instruction Manual

5

Error code troubleshooting (2 of 6)

Error

code

No.

Name Description Corrective action

1. Check the interface cable for damage. The hold wires may

be short-circuiting inside.

2. The CNC is maintaining this input, it could be waiting for an

IHS complete input from another torch.

3. If CNC interface cable is good and it is a one-torch system,

change PCB3.

Plasma gas pressure

under lower limit of

1. Inspect gas supply pressure and volume of gas remaining in

supply tanks.

0.34 bar (5 psi) – pre-flow 2. Verify gas regulator settings on gas console with cut chart.

3.45 bar (50 psi) – cutflow

(cutting)

3. See how to set your supply regulators (

Installation

section).

0.34 bar (5 psi) – cutflow

(marking)

4. Perform leak test procedure (

Maintenance

section).

1. Verify gas supply pressure settings.

2. Verify gas regulator settings on gas console with cut chart.

3. See how to set your supply regulators (

Installation

section).

4. Solenoid at off-valve is not opening. Verify power to valves,

disconnect plasma and shield hoses exiting off-valve. If

pressures decrease a valve is not functioning or no power to

the valve.

1. Verify input-line voltage. Voltage needs to be within 10 % of

nominal (120 VAC).

2. Verify fuses on PCB2.

3. Verify 120 VAC voltage on plug J2.4, pins 3 and 4 on PCB2.

4. Verify voltage on receptacle J2 on PCB2. Should be

approximately 1.65 VDC between pins 1 and 2.

5. If AC voltage on J2.4, pins 3 and 4, is greater than 108 VAC

and DC voltage on J2 is less than 1.485 VDC, replace PCB2.

1. Verify input-line voltage. Voltage needs to be within 10 % of

nominal (120 VAC).

2. Verify fuses on PCB2.

3. Verify 120 VAC voltage on plug J2.4, pins 3 and 4 on PCB2.

4. Verify voltage on receptacle J2 on PCB2. Should be

approximately 1.65 VDC between pins 1 and 2.

5. If AC voltage on J2.4, pins 3 and 4, is less than 132 VAC and

DC voltage on J2 is greater than 1.815 VDC, replace PCB2.

6. If AC voltage on J2.4, pins 3 and 4, is less than 132 VAC and

DC voltage on J2 is less than 1.815 VDC , verify the DC voltage

to J3.201 on PCB3. It should equal the voltage reading on J2. If

the DC voltage readings are the same and the wiring passes

continuity tests, replace PCB3.

6. If AC voltage on J2.4, pins 3 and 4, is greater than 108 VAC

and DC voltage on J2 is also greater than 1.485 VDC, verify

the DC voltage to J3.201 on PCB3. It should equal the voltage

reading on J2. If the DC voltage readings are the same and the

wiring passes continuity tests, replace PCB3.

32 Hold timeout

Hold signal was active for

longer than 60 seconds.

44

Low plasma

gas

pressure

45

High plasma

gas

pressure

Plasma gas pressure over

upper limit of 7.58 bar (110

psi).

46

Low line

voltage

Line voltage is close to or

less than the lower limit of

102 VAC (120 VAC -15%).

The normal lower limit for

operation is 108 VAC (120

VAC -10%).

47

High line

voltage

Line voltage is close to or

greater than the upper

limit of 138 VAC (120 VAC

+15%). The normal upper

limit for operation is 132

VAC (120 VAC +10%).

Loading...

Loading...