4.5.5 Typical Control Technique and Function Code Setting for the Crane System

The CS500 provides the built-in brake time sequence control function. This function

requires that an output terminal is set to "brake output"; that is, the corresponding function

codes F5-01 to F5-05 are set to 21.

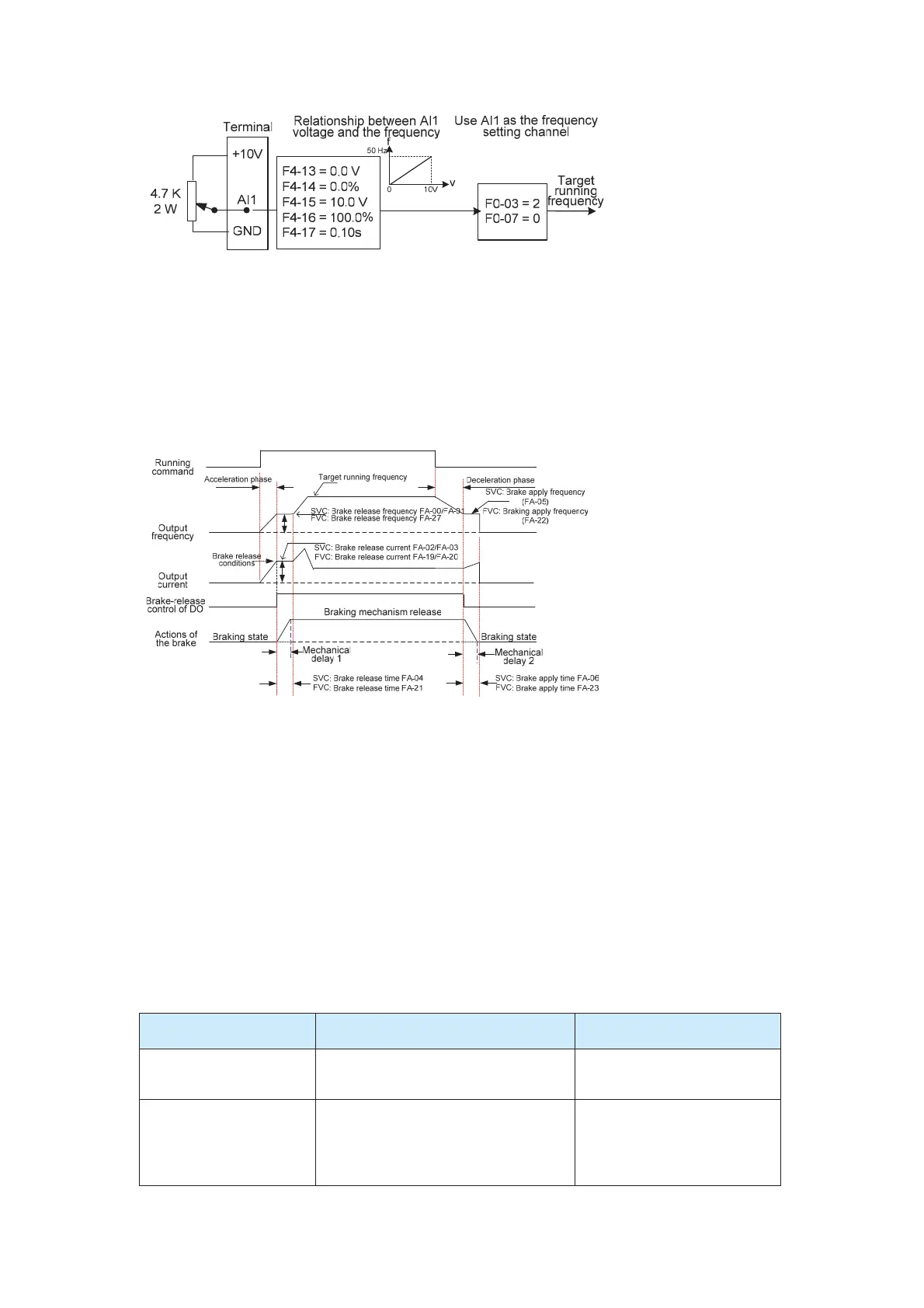

In the following figure, the function codes in SFVC (F0-01 = 0) and CLVC (F0-01 = 1) are

different. You need to select the corresponding function codes based on actual wiring and

set the function codes according to the figure.

Figure 4-11 Function code setting for the crane system

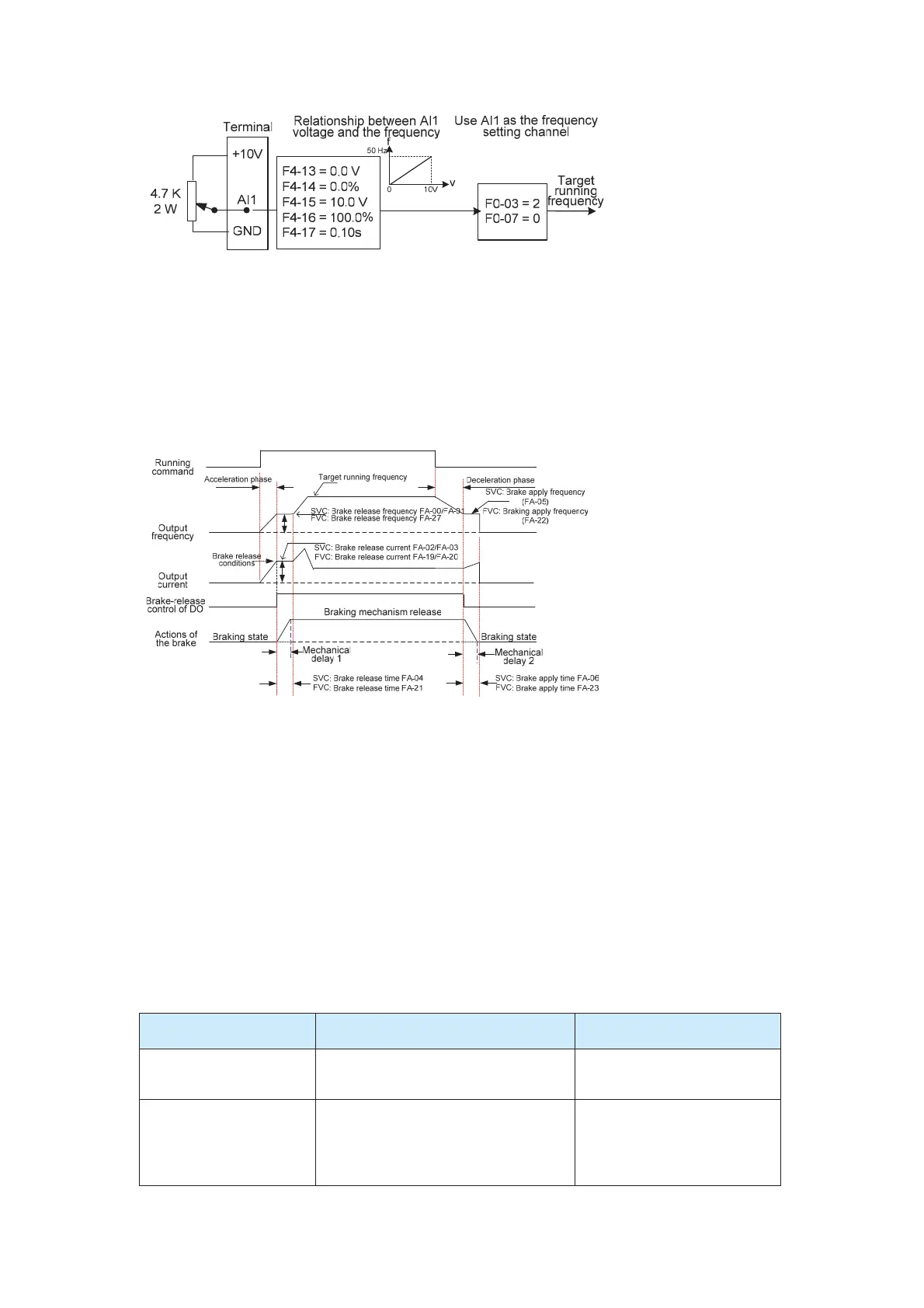

The braking mechanism keeps applied when de-energized and becomes released when

energized. Because the brake needs to act mechancially, there has to be a mechanical

delay between the brake output signal of the AC drive and the braking state. The open

time and close time need to be set based on the actual mechanical delay of the brake.

Theoretically, the open time and closing time must be slightly longer than the mechanical

delay to prevent hook gliding.

4.6 Motor Parameter Setting and Automatic Tuning

4.6.1 Motor Parameter Setting

The AC drive running in vector control (F0-01 = 0 or 1) requires correct motor parameters,

which is unnecessary for the V/F control (F0-01 = 2). To achive better driving performance

and running efficiency, the AC drive must obtain the correct motor parameters.

The involved motor parameters are listed in the following table.

Table 4-2 Setting of the motor parameters

Function Code Parameter Name Description

F1-00 Motor type

Common or frequency-variable

asynchronous motor

F1-01 to F1-05

z Rated powe

z Rated voltage

z Rated current

Model dependent, manually

input

efesotomas

on.com

Loading...

Loading...