26 - 3

Removal

1 Park the machine on firm level ground, engage the

parking brake and set the transmission to neutral.

Lower the loader arms to the ground.

2 Position the carriage centrally and rest the bucket on

the ground, remove the starter key.

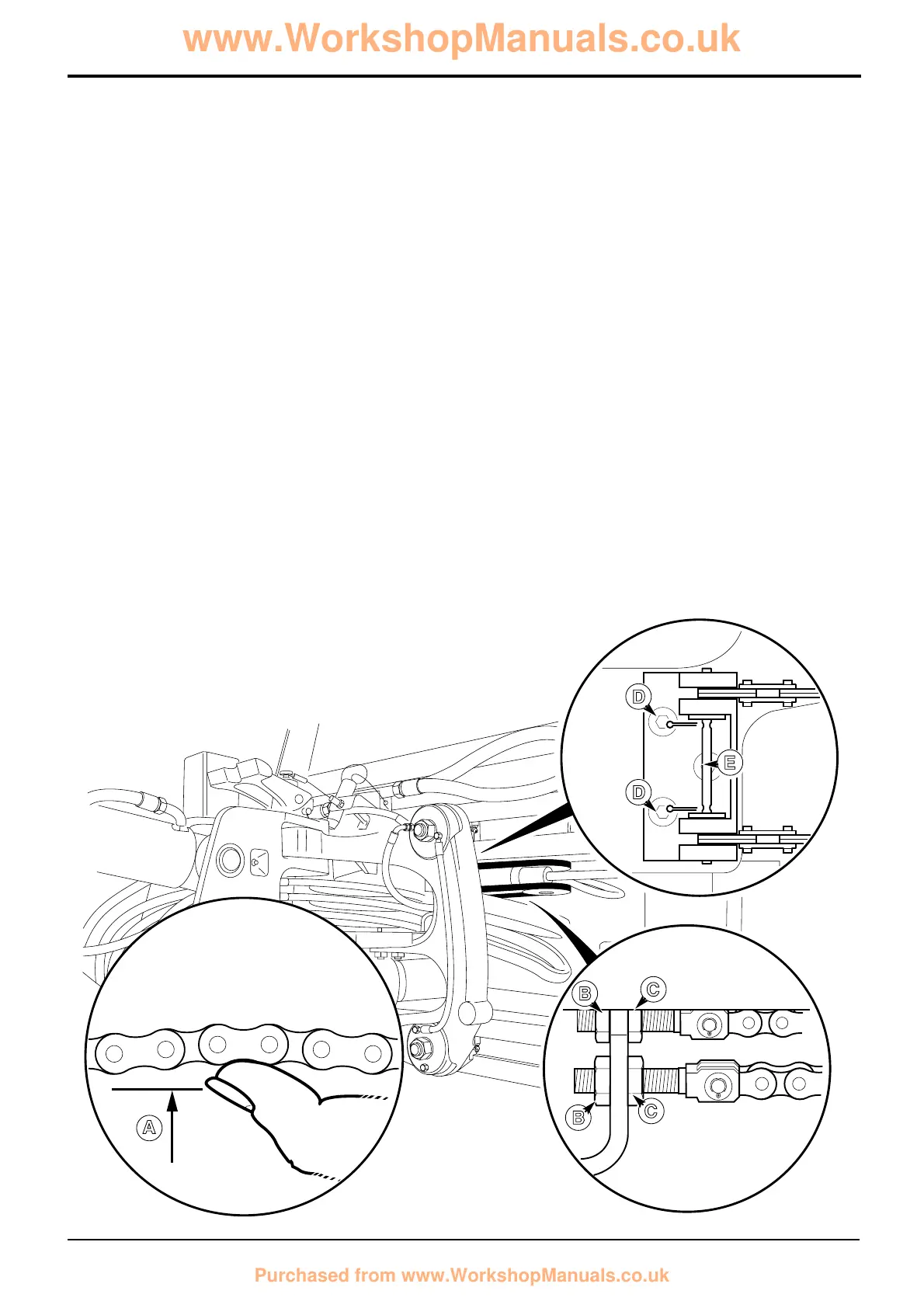

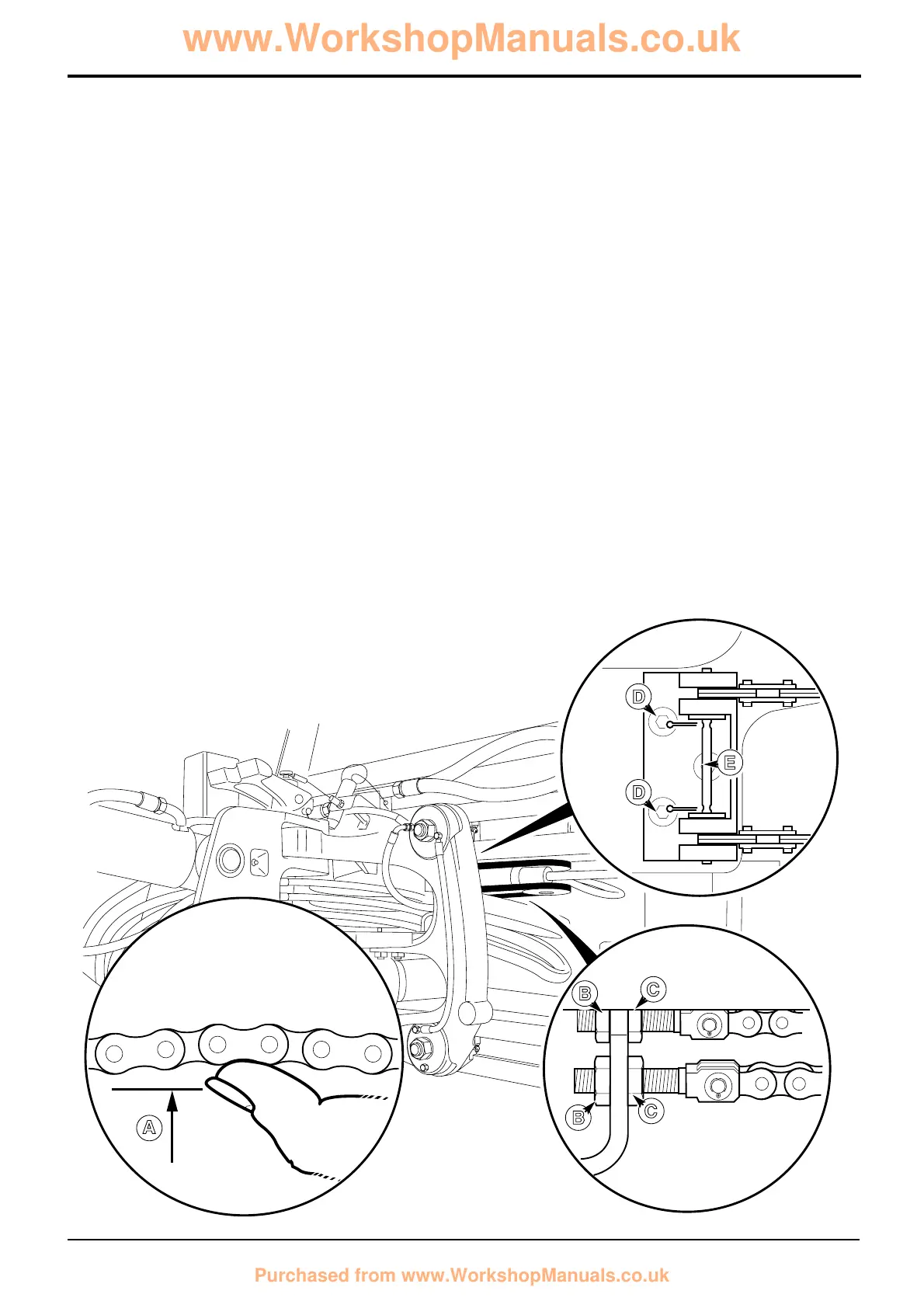

3 Undo and remove nuts B.

4 Remove split pins D and pin E.

5 Withdraw chains from the machine.

Assembly

1 Thread the chains around the pulley and secure to the

carriage with pin E, fit new split pins D.

2 Connect chain adjusters, tension chains as required,

see Check and Adjust.

Power Sideshift - Chain Adjustment

The chain tension should be checked at the initial 100 hours

service and every 500 hours.

Check and Adjust

1 Park the machine on firm level ground, engage the

parking brake and set the transmission to neutral.

Lower the loader arms to the ground.

2 Position the carriage centrally and rest the bucket on

the ground, remove the starter key.

3 Check the chain tension which should be 5 to 10mm

(0.19 to 0.39in) deflection A at the mid point. The

tension should be equal for all chains.

4 If adjustment is required, slacken locknuts C and adjust

on nuts B as required, tighten locknuts C on

completion.

5 Repeat steps 3 and 4 for the opposite pair of chains.

Note: When there is no thread left for adjustment fit new

chains.

6 Operate the carriage side to side several times and

recheck the deflection.

Section B Body & Framework

9803/3280

Section B

26 - 3

Issue 1

Service Procedures

A326830

B

B

A

C

C

D

D

E

Loading...

Loading...